What is Inspection and Measurement?

Automating visual inspections that require human “inspection” skills and experience

What is inspection and measurement?

This equipment automates visual inspections of metal parts to assess their external appearance. The processes to quantify and standardize visual inspections, processes that formerly required human experience and skill, can now be performed automatically in the in-line stages of a manufacturing line.

Main target products for JUKI’s inspection and measurement equipment

Engines for the automobiles and two-wheeled vehicles, electrical components cases for electric vehicles, etc.

Target (defective) areas for inspection

“Inspection and measurement” in a nutshell (illustration)

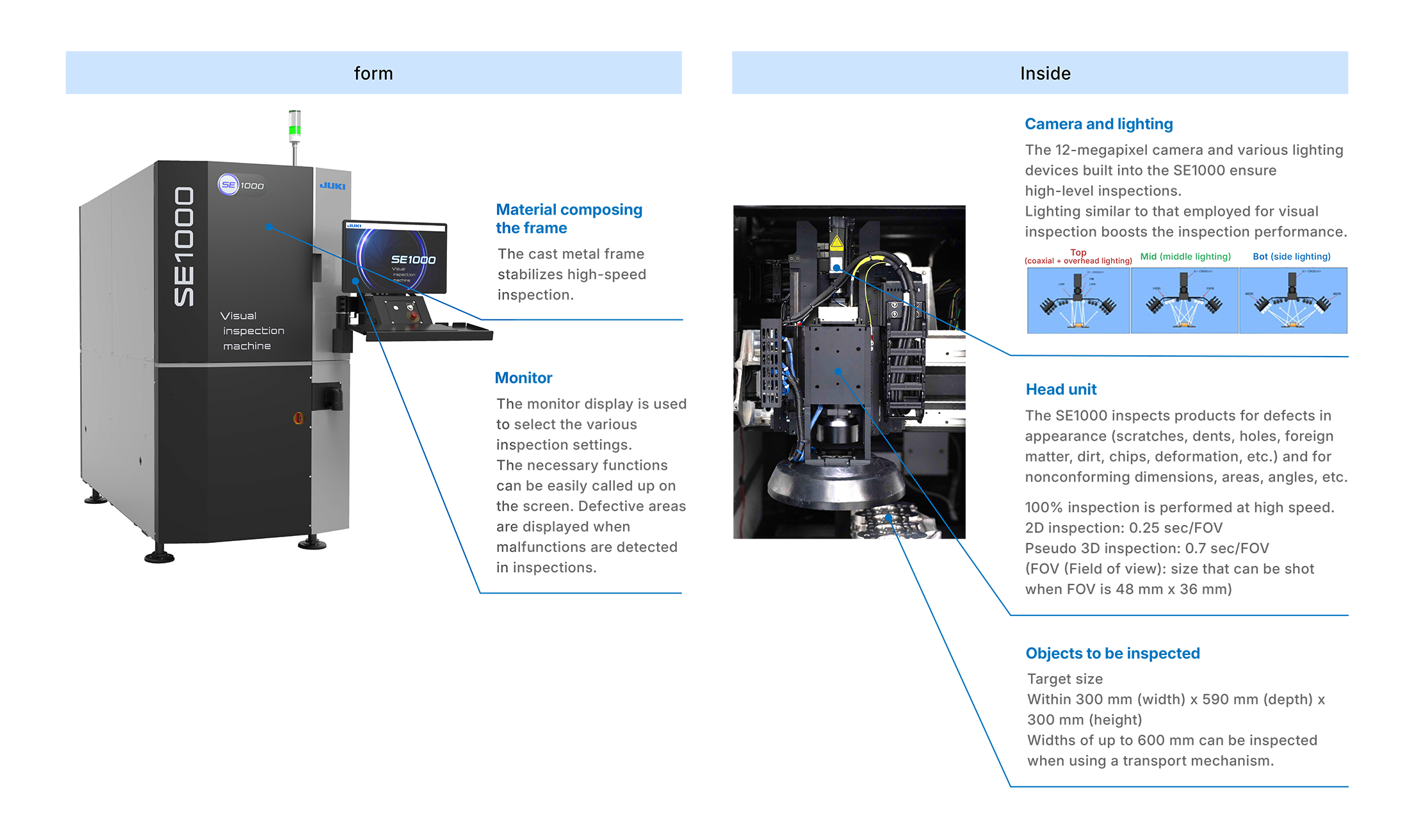

This section introduces the visual inspection machine SE1000.

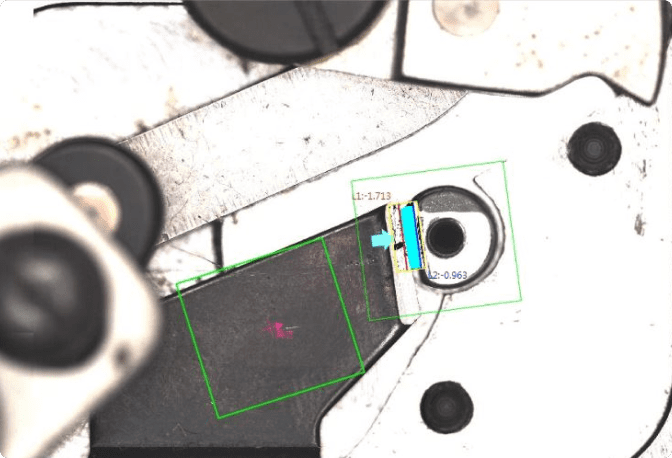

The SE1000 inspects parts for defects in appearance (scratches, dents, holes,foreign matter, dirt, chips, deformation, etc.) and for nonconforming dimensions, areas, angles, etc. Automatic visual inspections can be incorporated into a production line by deploying the SE1000 model configured with an automated product transfer function.

Visual inspection machine SE1000

Dedicated website for inspection and measurement

Dedicated website for inspection and measurement