What is an Industrial Sewing Machine?

The “seam” of a garment is the contact point between JUKI and the people of the world.

What is an industry sewing machine?

Industrial sewing machines are designed for high-speed performance, high quality, durability, and safety in sewing factory production. Diverse types of specialized industrial sewing machines are available to accommodate the various sewing items and areas to be sewn. JUKI also provides a large selection of automatic machines that complete multiple processes automatically to enhance quality and reduce the need for skilled labor in complex sewing operations.

JUKI’s industrial sewing machines

Features

| Industrial sewing machines (JUKI) | (Reference) Household sewing machines (JUKI) | |

|---|---|---|

| Functions | Industrial sewing machines are special-purpose sewing machines that perform specialized “sewing” processes such as lockstitch (straight stitch), zigzag stitch and buttonholing with high accuracy. The number of industrial sewing machine models used to produce a single item on a production line can range from several up to about 30. (The number of models required depends on the sewing item.) | Every household sewing machine model incorporates its own range of diverse or specialized “sewing functions.” General items such as blouses, bags and small articles can be completed with just one machine. |

| Speed | Approximately 600 to 8,500 sti/min | Approximately 700 to 1500 sti/min |

| Weight | Approximately 40 to 950 kg | Approximately 6 to 15 kg |

Major target items

“Industrial sewing machines” in a nutshell (illustration)

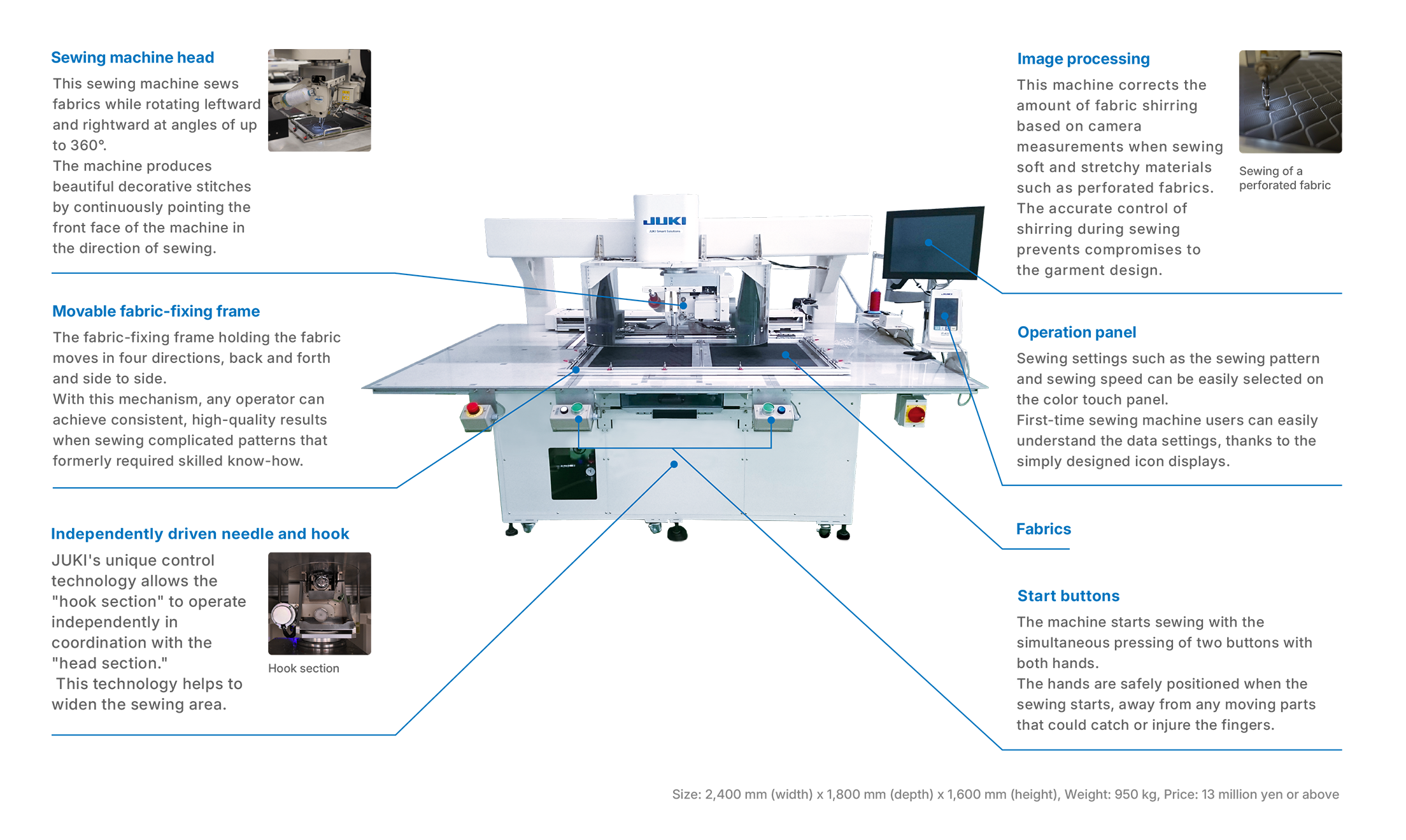

This section introduces the AMS-251, a 1-needle, CNC* sewing machine (head turning type), one of JUKI’s many different models of industrial sewing machines.

The AMS-251 performs decorative stitches on genuine leather or vinyl-coated cloth products such as car seats, luxury bags, and school satchels.

-

*

CNC: Abbreviation for Computerized Numerical Control

1-needle, CNC sewing machine (head turning type) AMS-251