SDGs-conscious Development Technology

SDGs-friendly core technology

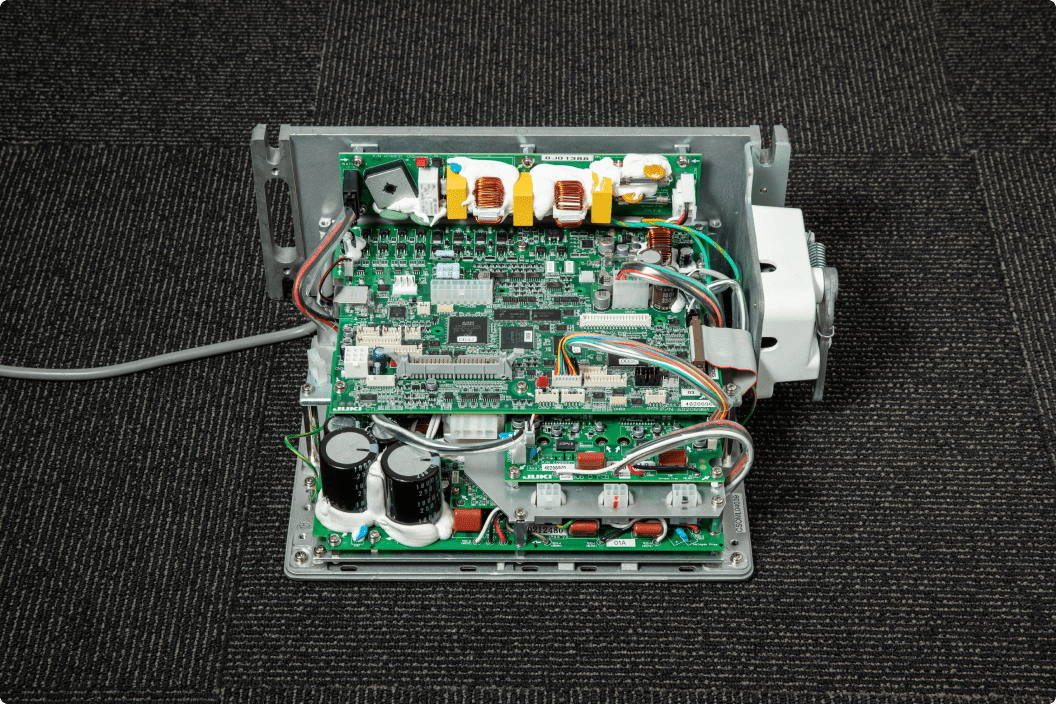

Energy-saving technology

Controlling and optimizing various motors to reduce power consumption

This technology optimizes power consumption through JUKI’s proprietary tuning technology that takes advantage of the characteristics of various motors to maximize performance without waste.

Many energy-saving technologies are employed, including a circuit design that shuts down the power circuit when the machine stops and then quickly restarts it when the machine is up and running.

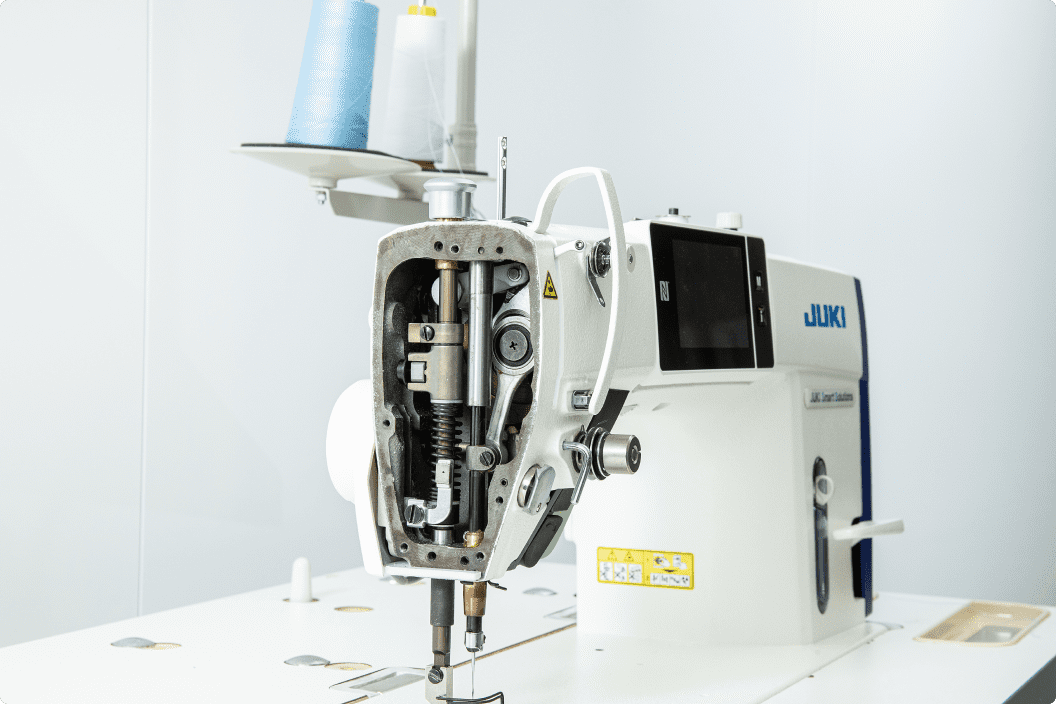

Drying technology

Maximizing trace amounts of lubricating oil to prevent oil stains on sewn items and reduce environmental load

This technology minimizes the amount of lubricating oil, an essential consumable for industrial sewing machines that rotate at high speed to dry the face plate portion.

This proprietary mechanism searches for optimum conditions for sewing machine operation. The needle bar is coated with a unique, ultra-hard DLC coating that will never damage machine parts, along with a small amount of “JUKI grease,” a semi-solid oil used to prevent wear.

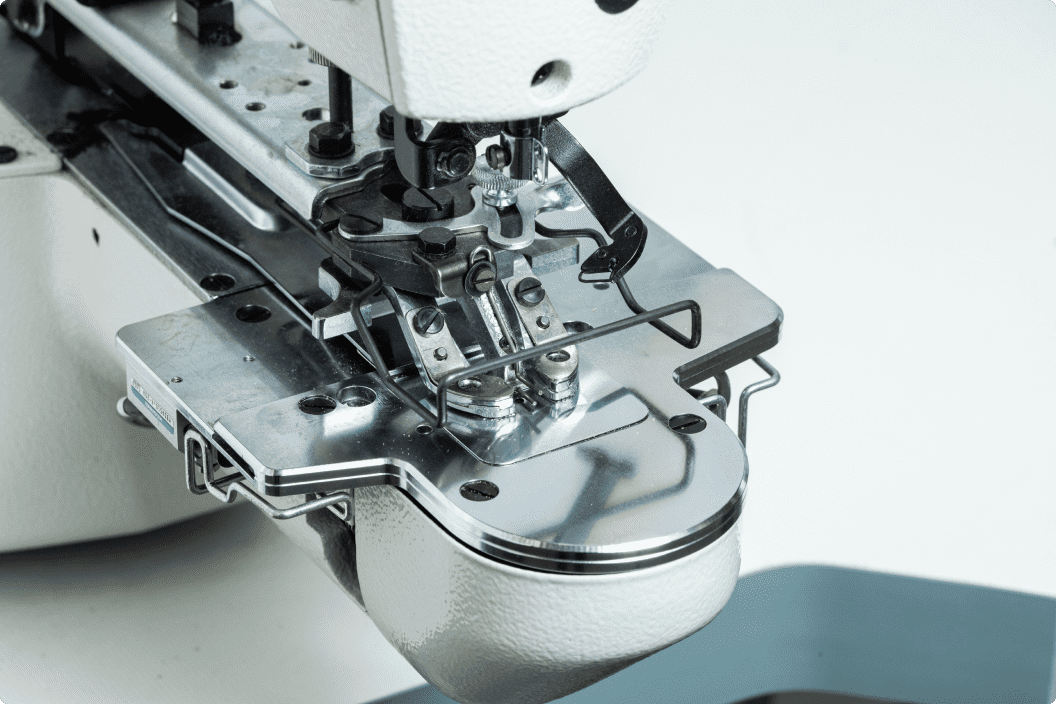

Bird’s nest preventing/Shorter-thread remaining technologies

Eliminating the work of picking threads and improving sewing quality on the fabric backing

This technology prevents the thread from tangling in a bird’s nest at the beginning of sewing and cuts the thread to the shortest possible length at the end of sewing.

The thread gripper grabs the needle thread at the beginning of sewing and grips it firmly until the end of sewing.

After the normal thread-trimming operation and sewing operation are completed, the knife trims the needle and bobbin threads at the end of the stitch and the needle thread at the beginning of the stitch, and the remaining threads are sucked in.

Operator-friendly technology

Equipped with features that provide comfort during use and reduce the environmental load

As industrial sewing machines are operated by “people,” we are working to develop “people-friendly products and equipment” that reduce worker fatigue and maintain a clean and stress-free environment with reduced noise/vibration and a mechanism to collect thread and fabric-edge dust.

We are also developing products that reduce power consumption to achieve carbon neutrality by 2050 and designing circuits that maximize performance without waste by harnessing the characteristics of the various motors used.

We also turn to recycling as a principle means of “Reducing/Reusing” JUKI products and reducing waste.

Promotion of JUKI SUSTAINABLE PRODUCTS

We have established the “JUKI SUSTAINABLE PRODUCTS” certification system to achieve carbon neutrality and the SDGs materialities that JUKI has set forth.

Twenty-two sustainable assessments are performed to evaluate and certify products that meet the company’s internal standards, in addition to the 38 environmental assessments performed on “JUKI ECO PRODUCTS.”

We are working to enhance functionality and performance of products to solve various social challenges of reducing Scope 3 CO2 emissions, reducing resource loss, and improving the working environments of our customer factories.

“JUKI SUSTAINABLE PRODUCTS” mark design

The “j” in JUKI is designed using the logomark design colors for development goals No. 8 and No. 12 from the 17 SDGs.

The core design aim for “JUKI Sustainable Products” is to make progress towards goal No. 8 “Job Satisfaction and Economic Growth” and goal No. 12 “Responsibility to Create and Use.”

The new design for the “j” in JUKI expresses our commitment to achieving these two goals.

The gold medal motif in our design for the ENERGY SAVING mark, a testament to a product’s success in achieving a 25% reduction in power consumption, expresses the confidence and pride of JUKI’s advanced technology in achieving its goals.

Major items for sustainability assessment

| Items related to the SDGs | Contents | Specific examples |

|---|---|---|

|

No.12

Responsible Consumption and Production |

Contribution to CO2 emission reduction | Reduction of power consumption, reduction of material emission source units |

| Contribution to resource loss | Consumable material loss, garment loss, sewn material loss | |

| Support for technological innovation at customer factories | Automation, setup-free | |

|

No.8

Decent Work and Economic Growth |

Creation of better working environments for customers | Reduction of vibration, noise, heat generation, dust, etc. |

| Creation of a society where anyone can play an active role | Equipment that can be used even by persons with disabilities |

Promotion of ECO PRODUCTS

JUKI manufactures products that remain environment-friendly throughout their entire life cycles, from the design, manufacturing, transportation, and use to recycling and final disposal.

The JUKI ECO PRODUCTS certification is awarded to products that pass 38 assessments related to the environment.

“JUKI ECO PRODUCTS” mark design

Depicting the letters “e, c, o” as a pie chart

The “green” area, which expands as it moves to the right, expresses JUKI’s determination to further grow its lineups of environment-friendly JUKI products and its desire to return the earth to its original, green state.

Major items for environmental assessment

| Materials and parts procurement stage | Manufacturing and distribution stage | Usage stage | Recycling and disposal stage | |

|---|---|---|---|---|

| Environmental safety and preservation | Elimination/reduction of hazardous substances | Reduction of noise and vibration | Easier separation of environmentally hazardous substances | |

| Shift to resource saving | Reduction of raw materials Use of recycled materials |

Long-term credibility | ||

| Shift to energy saving | Improvement of transportation efficiency | Reduction of power consumption Reduction in the consumption of consumable goods |

||

| Recyclability | Recycling Ease of separation and sorting |