Initiatives at the JUKI Group

nvironment-conscious design at the Tama head office

Various environmental considerations are incorporated into the design of the head office building in Tama-shi, Tokyo.

Along with energy-saving equipment and systems such as rainwater treatment equipment and highly insulated double-glazing (Low-E) glass, we are actively introducing a BEMS system that measures and monitors energy consumption by energy type (electricity, gas, and water), use, and zone and enables operational improvements.

The building has also acquired a rank “A”-equivalent rating in the CASBEE assessment (Comprehensive Assessment of Building Environmental Efficiency) for environmental performance.

In addition to outstanding environmental performance, the building is also designed for ease of use, with spatial layouts that allow people to communicate and interact spontaneously and organically.

-

Rainwater utilization

Rainwater collected on roof surfaces is treated by sand filtration and sterilized for reuse as toilet flushing water or for other purposes. -

Promotion of rooftop/premises greening

By greening the rooftop and premises as much as possible (approximately 2.5 times the greening standard area of the Tokyo Metropolitan Government), we improve building insulation and contribute to heat island control.

Our “greened” environments also make workplaces more comfortable by alleviating employee fatigue and promoting mental peace of mind. -

Solar radiation shielding

Highly insulated double-glazing (Low-E) reduces solar radiation load and air-conditioning load.

In addition, a titanium oxide coating applied to the exterior walls and glass promotes self-cleaning by rainwater and light from the sun, natural forms of energy. -

Lighting control

The main component is a high-efficiency, long-life Hf fluorescent lamp. A dimming sensor dims and brightens the spaces based on the natural lighting conditions to ensure that the needed brightness is achieved with as little energy as possible.

Activities to promote energy-saving in production

A newly formed energy-saving promotion team made up of members from manufacturing sites is promoting activities to reduce CO2 emissions and other environmental loads in production, the most energy-intensive of the JUKI Group’s business activities, based on the JUKI Group’s know-how.

Main Initiatives

- Promote the introduction of renewable energy.

- Switch to high-efficiency equipment in line with capital investment plans.

- Horizontally deploy energy-saving initiatives.

- Improve the skills of members and develop human resources capable of horizontal deployment.

Examples of the energy-saving promotion team’s activities and reduction effects (including expected values)

-

Introduce renewable energy.

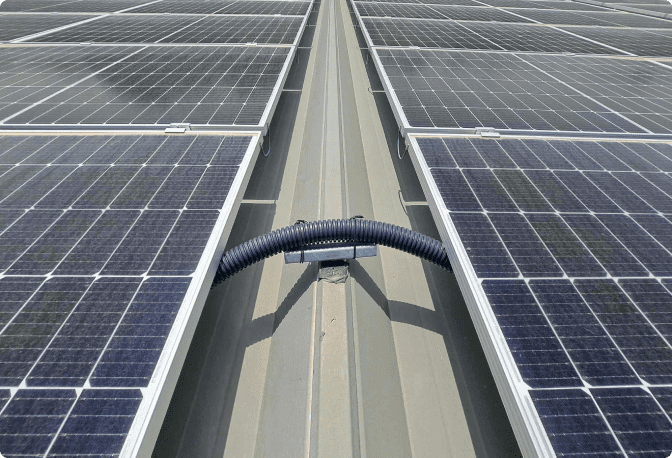

We will introduce solar power generation as a renewable energy.

We will continue to expand the number of factories partially or fully powered by solar power cells.

Reduction effect 450t-CO2/year (2 factories)

-

Loop air piping.

The experienced and skilled JUKI group company employees and the members of the energy-saving promotion team investigated waste at the subject factory.

After investigating compressor operating conditions, piping conditions, air usage, and the like, the team improved the efficiency of energy circulation by looping the piping, reviewing the use of receiver tanks, and so on.

We will horizontally expand the system to other group company factories.

→ Reduction effect 74t-CO2/year (3 factories) -

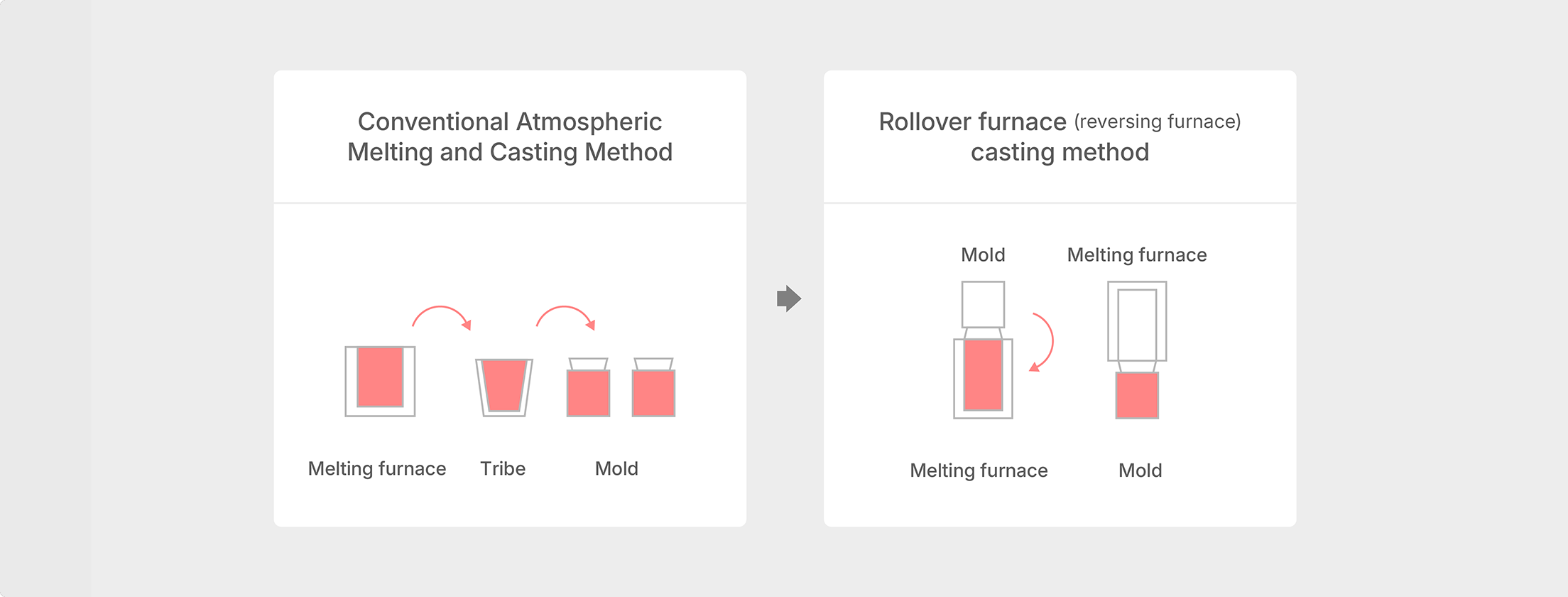

Improve quality and reduce energy usage by changing the casting method (smarter casting).

In the earlier method, the molten material was placed in a large melting furnace, poured into a container called a “trivet,” and poured into the “mold.” A new method of pouring directly from the melting furnace into the “mold” prevents the temperature from dropping and stabilizes quality.

Improved quality saves energy (reduces CO2 emissions) by reducing the number of products that are either defective or require reworking.

Energy-saving activities at factories

CO2 emission reduction is being promoted through the introduction of renewable energy, upgrades to high-efficiency equipment and facilities, and the activities of the energy-saving promotion teams.

JUKI’s CO2 emissions in fiscal 2022 were reduced to 96% of the planned level.

- Introduce a solar power generation system.

- Hold a debriefing session on CO2 reduction activities.

- Replace with high-efficiency equipment and facilities.

- Conduct energy-saving diagnostics using external resources.

- Save energy through the use of exhaust heat.

Waste reduction initiatives through a refurbishment business

The JUKI Group is reducing waste and realizing a circular economy through operation of the JUKI Green Rewards Program, a refurbishment business.

Under its JUKI Green Rewards Program, JUKI collects and refurbishes products that were originally intended for disposal by customers.

JUKI collects its customers’ used products and refurbishes them using proprietary JUKI technologies. JUKI is working to build a recycling-oriented business model by providing its customers with refurbished machines.

The image is based on the word “Leaf” for green.

The image is based on the word “Leaf” for green.