Procurement

Basic policies for procurement activities

The global procurement policies of the JUKI Group place high priority on “Compliance with laws and regulations,” “Coexistence and co-prosperity,” and “Fair and equitable evaluation and selection” with suppliers.

Compliance with laws and regulations

We conduct our global procurement activities in compliance with the regulatory requirements and standards governing safety and health, global environmental protection, legal compliance, fair trade, corporate ethics, etc.

Coexistence and co-prosperity

We actively communicate with suppliers to deepen our relationships of trust and conduct manufacturing activities that encourage mutual growth. As an active supporter of co-existence and co-prosperity, we regularly hold a “workshop for cooperating companies” to share JUKI’s initiatives, sense of direction, and goals.

We aim for coexistence and co-prosperity with cooperating companies by learning from each other as good partners and existing and developing together sustainably into the future.

Fair and equitable evaluation and selection

JUKI selects suppliers based on a comprehensive evaluation of the following three items.

- Quality, price, delivery time, etc. of procured products

- Technical capabilities

- Reliability, etc. as a company

We always respond sincerely and provide fair and equitable opportunities to a new entrant, regardless of whether the business is large or small, domestic or overseas.

Suppliers who make notable contributions to QCD are commended at JUKI’s regularly held “workshop for cooperative companies.” Every supplier who meets JUKI’s quality assessment standards is issued a Certificate of Guaranteed Delivery.

Enhancing the quality of delivered parts

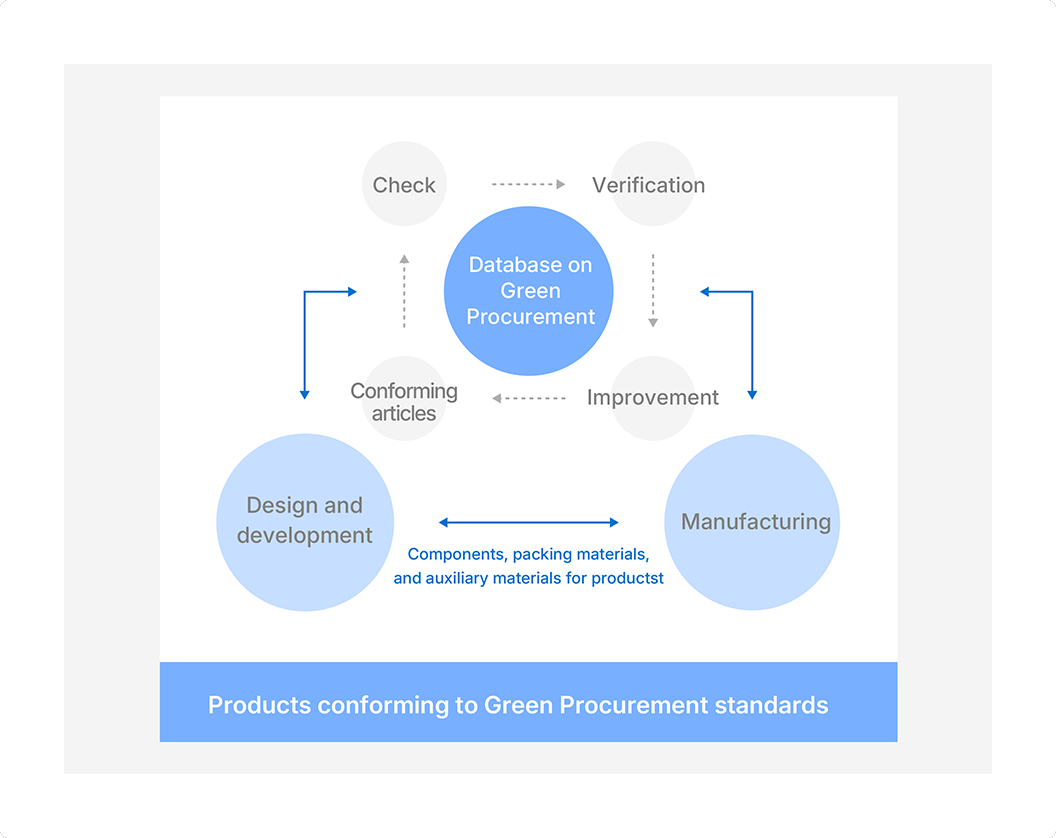

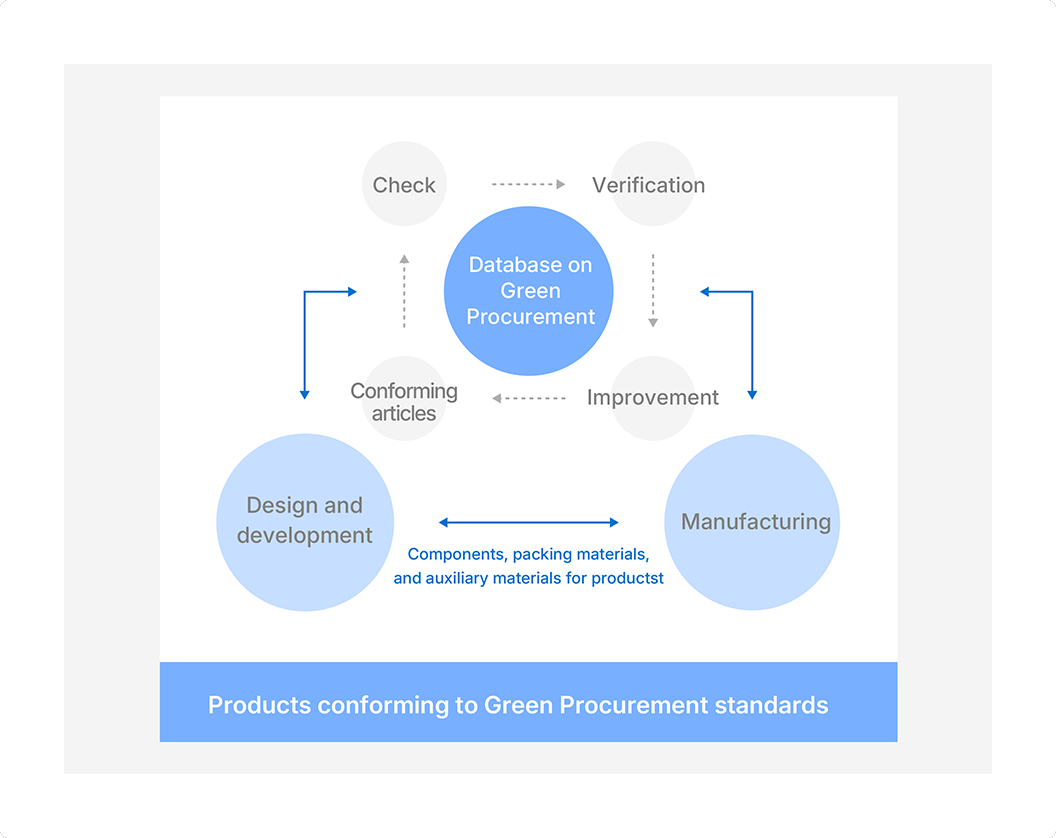

JUKI rechecks manufacturing quality continuously and redundantly.

As part of this quality effort, we conduct “audits” on technical and management functions in cooperation with major suppliers in Japan and overseas. If improvements are observed, we activate the PDCA cycle to increase the inspection-free rate.

Activities like these deepen our dialogs with suppliers in pursuit of higher-quality delivered parts and the building of long-term relationships of trust.