Testing and Evaluation Supporting Product Development

As many of JUKI’s products are used for the manufacture of goods in different parts of the world, they must operate stably in the widest possible range of working environments.

To prevent problems with strength, safety or durability, JUKI’s evaluation tests employ forefront 3-dimensional CAD and testing equipment that virtually simulates physical phenomena such as power, heat, vibration, and electromagnetic radiation. JUKI’s evaluation testing ensures reliable quality and safety at the highest levels.

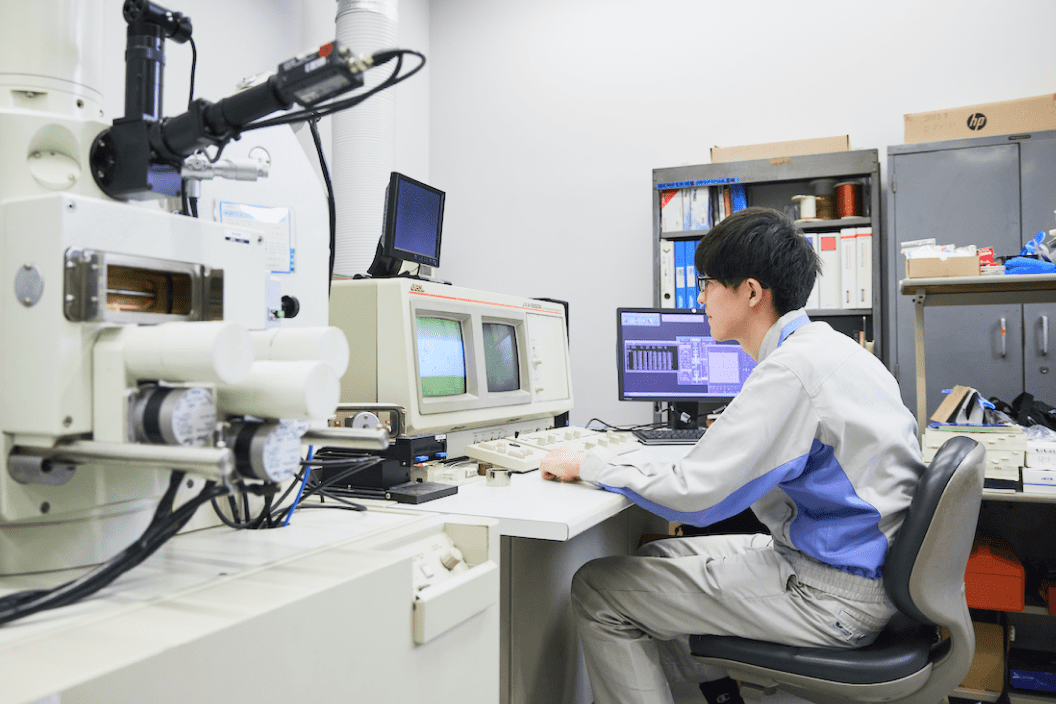

Material research with an electron microscope

A scanning electron microscope (SEM) visualizes the microscopic structures of materials at the highest possible resolution. JUKI’s R&D and quality management departments use SEMs to develop new materials and elucidate the mechanisms of product breakage by observing the physical properties of materials, analyzing their surface morphologies and organizational structures, and conducting fracture surface and wear analyses.

Elemental analyses with the EPMA

The electron probe micro analyzer (EPMA) is used for micro-region elemental analyses. The instrument can evaluate the physical properties and compositions of substances by quantifying elemental compositions at high resolution. JUKI uses the EPMA for the quality management control of product materials.

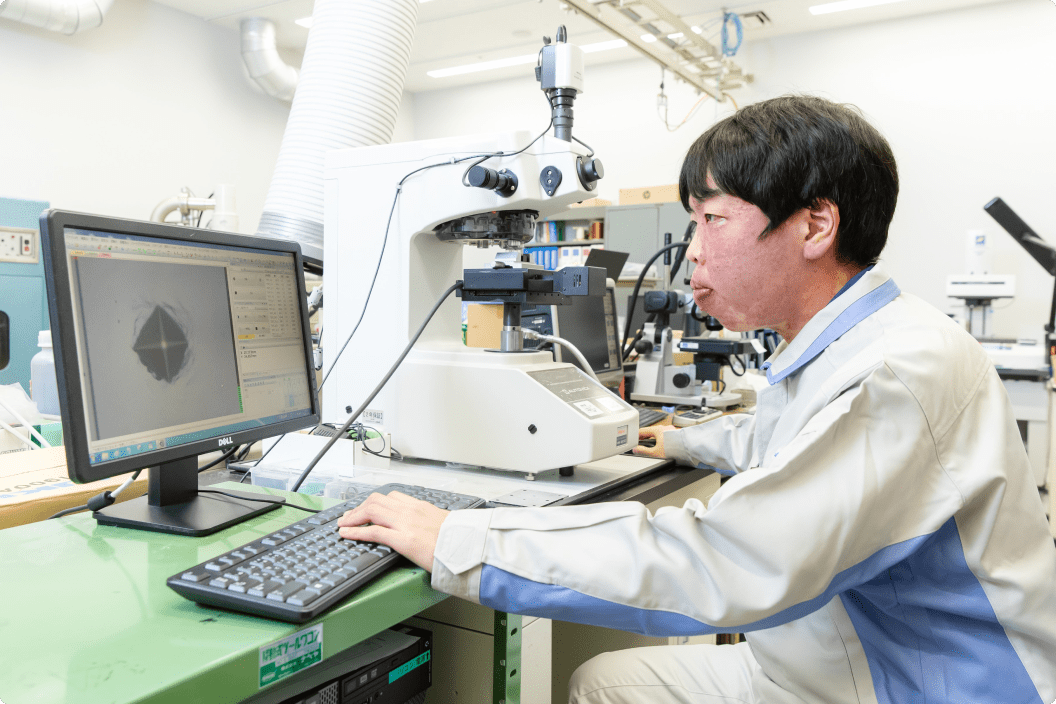

Hardness test using a Vickers hardness tester

The Vickers hardness tester measures the hardness of substances. JUKI uses the instrument to evaluate the hardness and durability of materials for optimization at the product design and manufacturing stages and the detection of defective materials.

Test using an electrostatics tester

Electrostatic tests are performed to confirm that the products will not break or malfunction due to exposure to static electricity, an ever-present force during operation. Quality determination tests are conducted with equipment that generates static electricity.

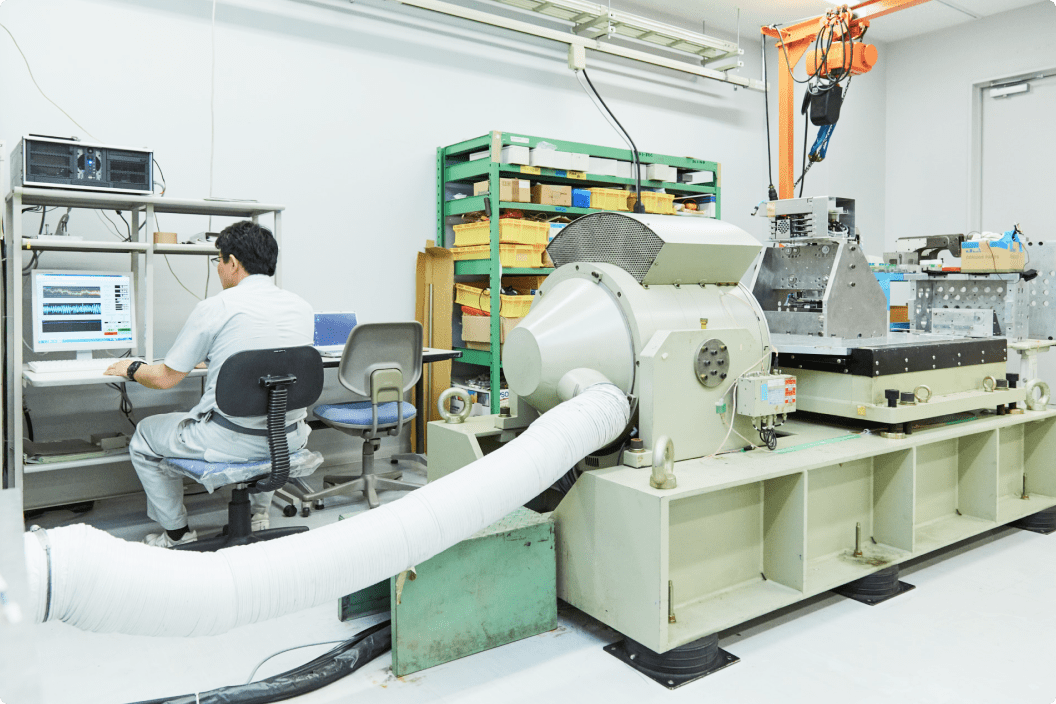

Vibration test using a vibration exciter

A product may break or fail when subjected to vibration over long hours of operation. JUKI develops hard-do-break products by exposing prototypes to the various types of vibration possible during product operation, and maintaining the exposure over extended testing periods.

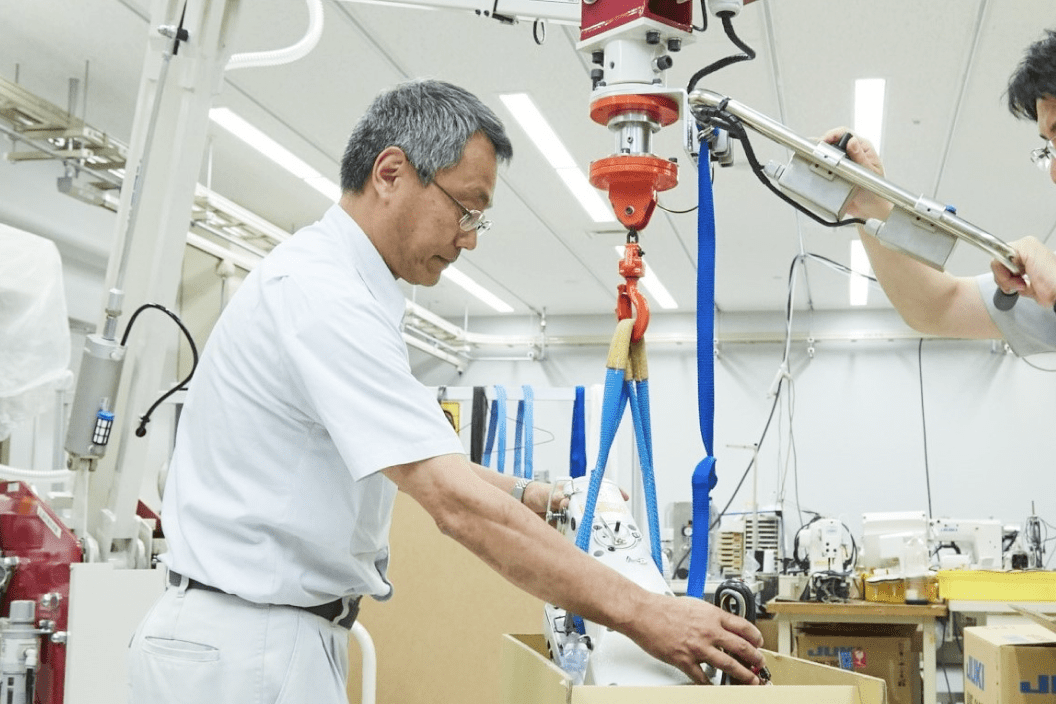

Product packaging drop test

JUKI researches optimal packaging methods to protect products from falling accidents by conducting real-world drop impact tests that simulate the journey from factory shipment to customer delivery.

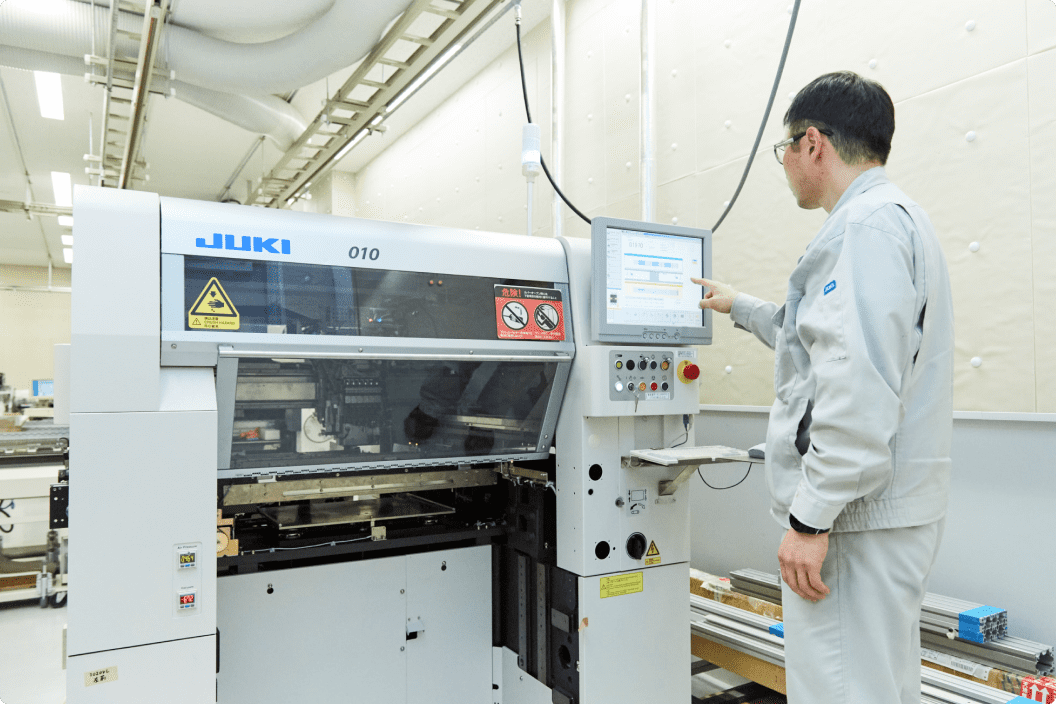

Durability test on chip mounters

Chip mounters must achieve micron-scale precision and have the durability to ensure uninterrupted 24-hour operation. JUKI conducts long-term continuous operation to ensure functional integrity and reliable performance over extended periods of time.

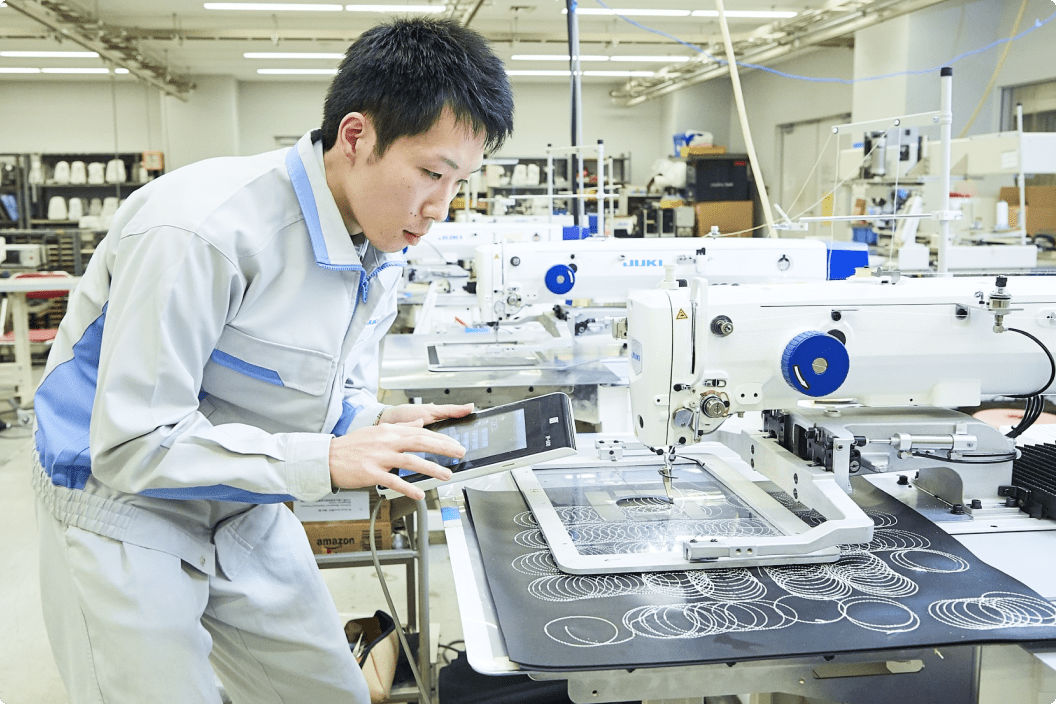

Sewing test on industrial sewing machines

Sewing factories process a wide variety of fabrics and threads for the manufacture of diversified sewing items. To produce beautifully finished seams that match the sewing items under any sewing condition, regardless of the fabrics and threads used, a constant focus for JUKI in the various sewing tests it performs is to broaden the range of applicable materials and items.

Noise rating in a semi-anechoic chamber

A full understanding of a product’s operating noise allows a product designer to reduce operating noise, which in turn reduces noise stress and improves the comfort of the work environment. A semi-anechoic chamber filters out interfering sounds from outside and eliminates sounds reflected from interior wall surfaces. The resulting quiet allows a manufacturer to precisely measure the source and acoustic characteristics of the noise generated by a product or piece of equipment.