What is Automated Warehouse?

Realization of DX (digital transformation) in parts management.

Smartification of the management of all parts.

What is an automated warehouse?

JUKI’s automated warehouse automates the inventory management of small parts and small, light-weight articles and their entry and dispatch to and from the warehouse.

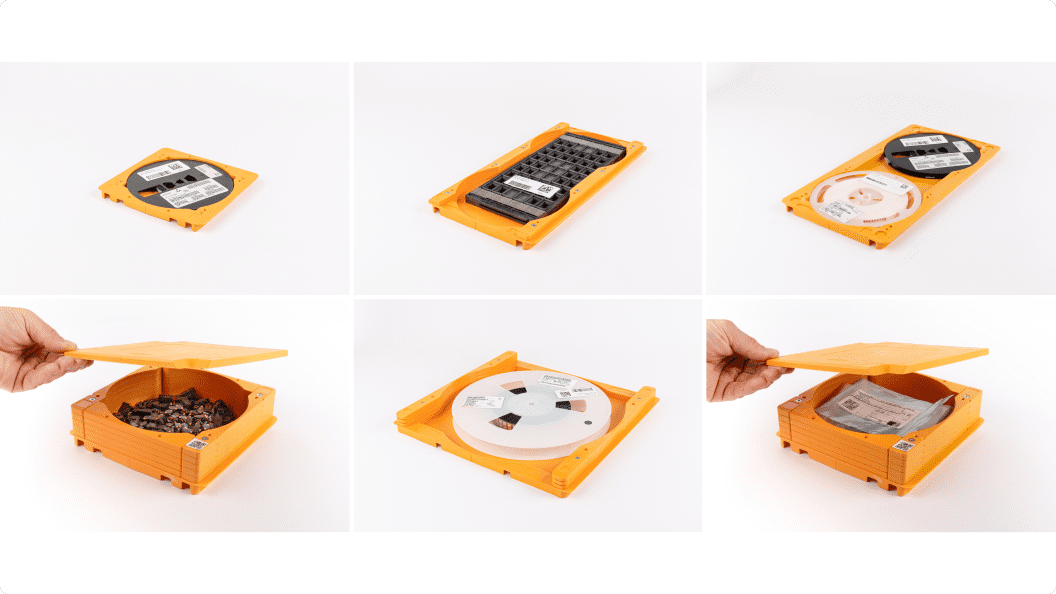

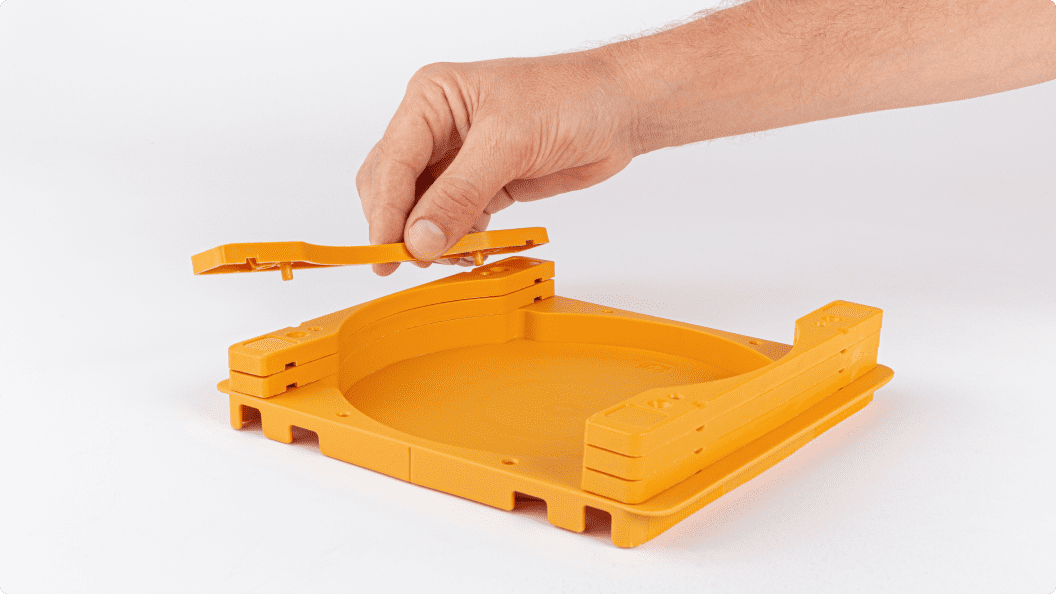

Variations in the types and sizes of parts or articles can be easily accommodated by switching the storage trays. The automated warehouse prevents the intrusion of dust, maintains quality in a humidity-controlled space, and ensures the security of the stored assets. The automated warehouse also saves space by allowing for storage without spatial gaps. Bar-code management enables the retrieval of required items from large inventories with pinpoint accuracy.

Example of trays and storage types in JUKI’s automated warehouse

“Automated warehouses” in a nutshell (illustration)

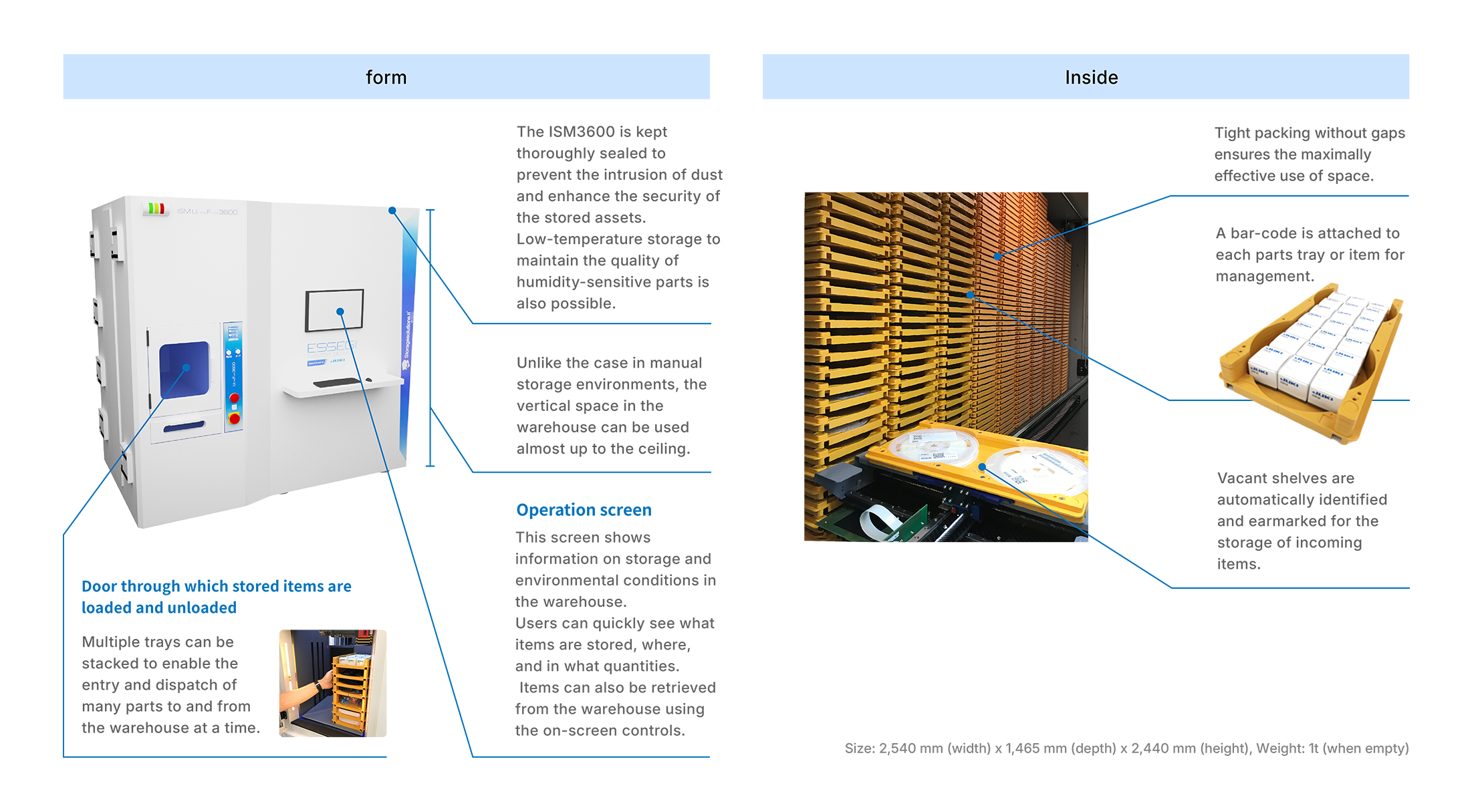

This section introduces the ISM3600 Intelligent Storage Management System from within JUKI’s lineup of automated warehouses.

The ISM3600 automates the inventory management of small parts and small, light-weight articles and their entry and dispatch to and from the warehouse. A maximum of 3,600 trays can be stored.

-

*

The maximum tray storage capacity depends on the tray size.

Intelligent Storage Management System ISM3600

Dedicated website for automated warehouses

Dedicated website for automated warehouses