What is SMT-related equipment?

This equipment manufactures electronic circuit boards, the core components of electronic devices.

What is SMT-related equipment?

Surface mounting-related equipment is manufacturing equipment used mainly to mount electronic components such as IC chips, semiconductors, and capacitors on electronic circuit boards to complete them. The various types of Surface mounting-related equipment in a factory manufacturing electronic circuit boards are linked within a system that outputs completed products almost automatically.

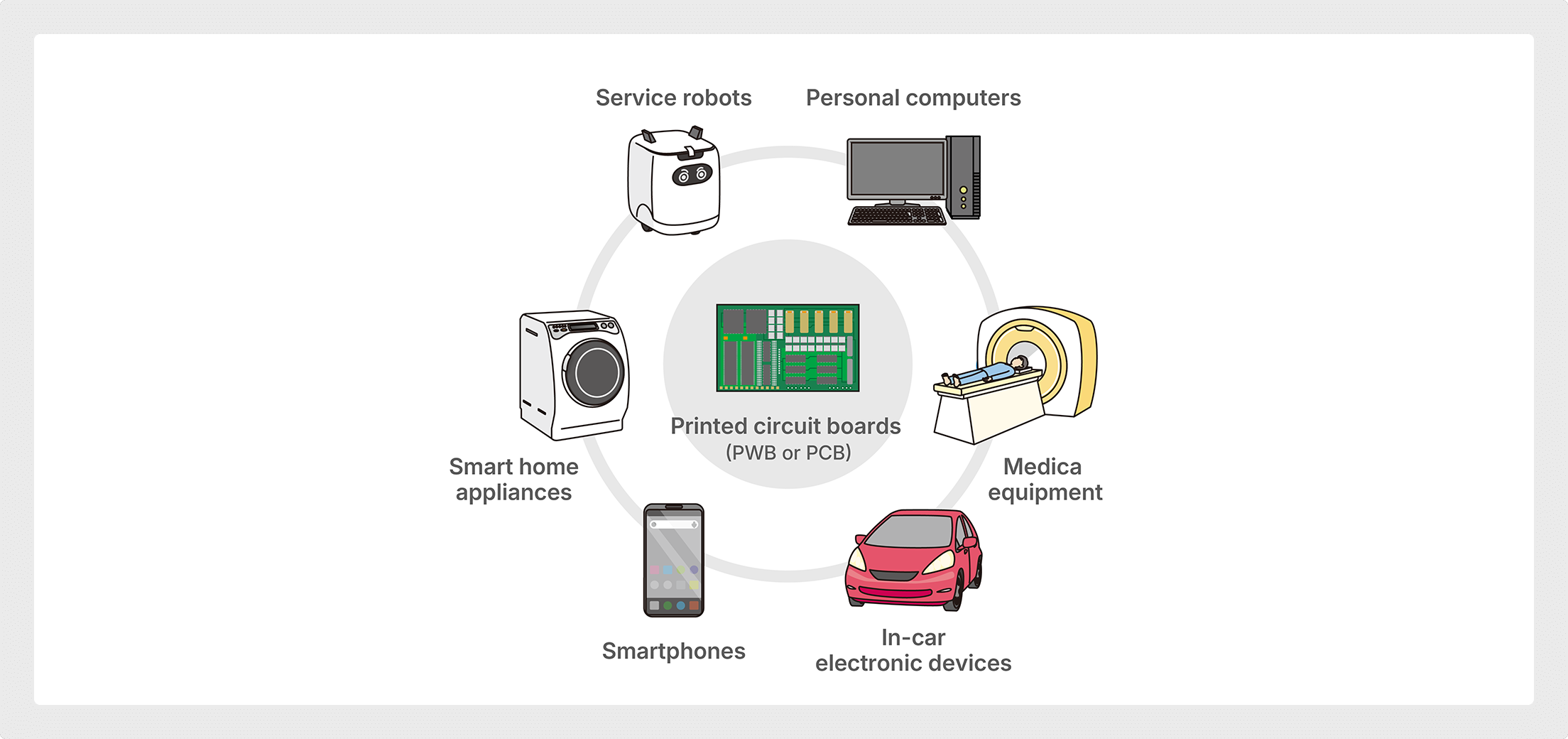

Electronic circuit boards are incorporated in almost all of the various machines and devices regarded as indispensable to daily life, from smartphones and home appliances to vehicles such as cars and trains and the equipment in offices, hospitals, and factories.

Examples of products in which electronic circuit boards are incorporated

Manufacturing process for electronic circuit boards

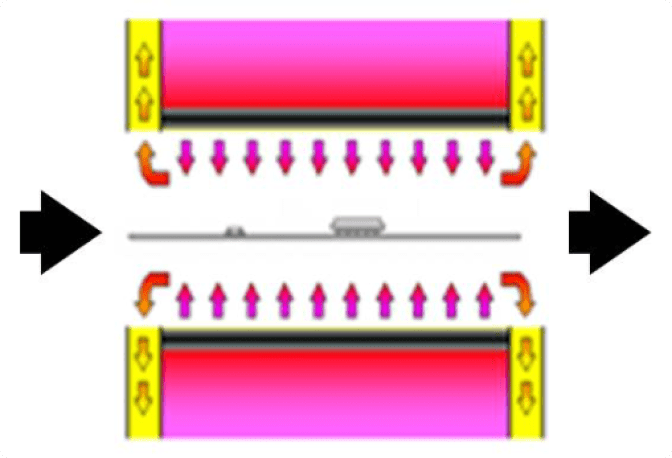

Screen printing process

This is the process of printing solder paste on the PWB on which components will later be mounted. The solder paste, which acts as an adhesive, is printed on electronic circuit boards in bulk using a thin plate called a screen.

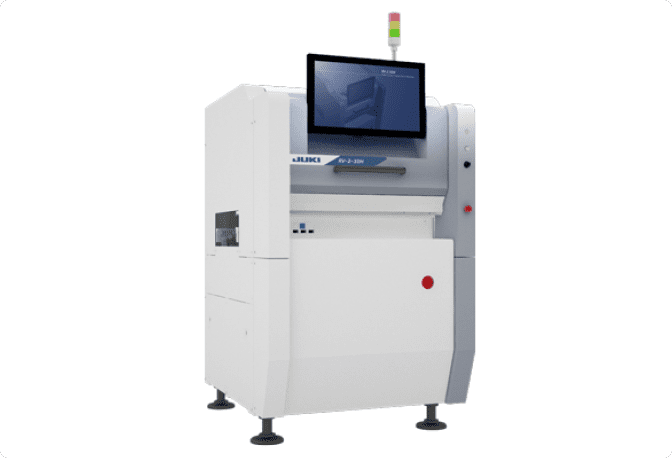

Inspection process

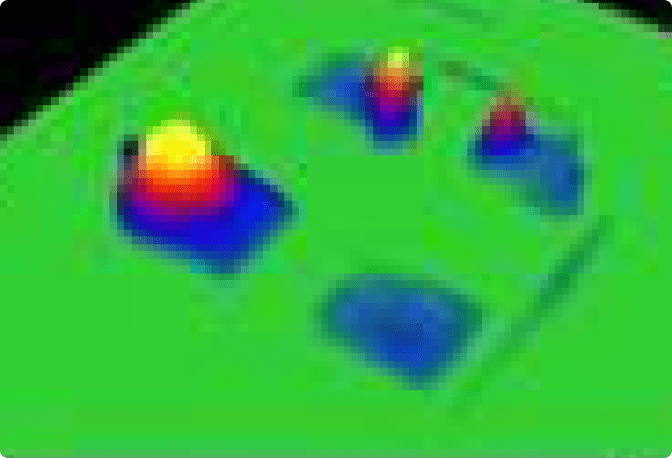

This is the process of inspecting whether the solder paste is correctly printed on the PWB. The printed solder is inspected from multiple directions to measure the area, height, and quantity of solder and check its misalignment. Differences in shadow illuminance are analyzed by illuminating the PWB from eight directions. The PWB can also be inspected with a 3D sensor.

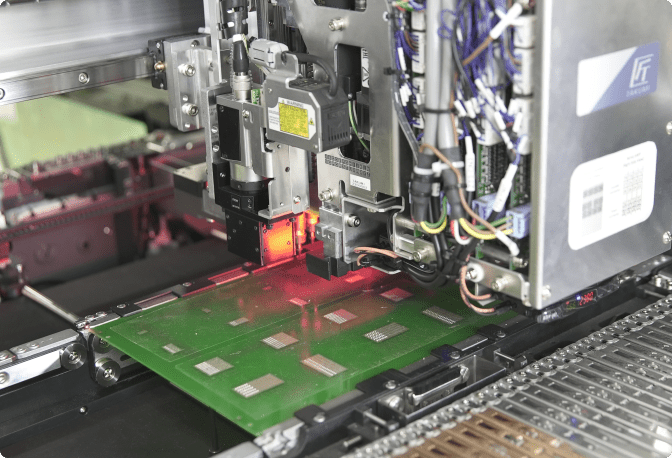

surface-mounting process

This is the process of placing components at the locations on the PWB designated in the circuit design.

Components come in various shapes and sizes, both large and small, and must be placed with extreme accuracy at the designated locations on the PWB at extremely high speeds. The nozzle picks up and places components and then the head brings components to the placement locations. Different types of nozzles and heads are deployed according to the components to be placed, such as high-speed types designed for the placement of very small components. Multiple machines are connected and used together in production sites. The head travels at a high speed and places about 26 components on the PWB per second.

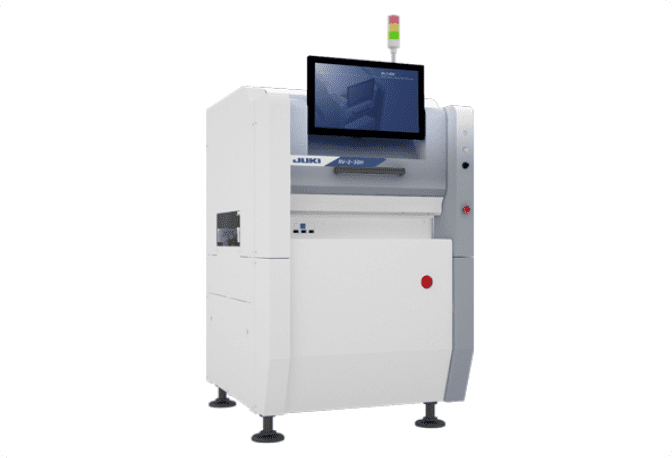

Inspection process

This is the process of inspecting whether the components are placed at the correct locations. Electronic circuit boards undergo comprehensive evaluations using 3D and 2D camera imagery to detect various defects. This inspection checks for missing or misaligned components, floating components, character recognition issues, and soldering quality all at once. Each electric circuit board is either accepted or rejected based on the assessments.

Reflow process

This is the process of fixing components on the PWB by melting the solder. The components are fixed by melting the solder on the soldered PWB in hot air (140℃ to 250℃), or dipping the PWB in a solder bath and remelting and cooling the PWB. (No product of this reflow process is available from JUKI.)

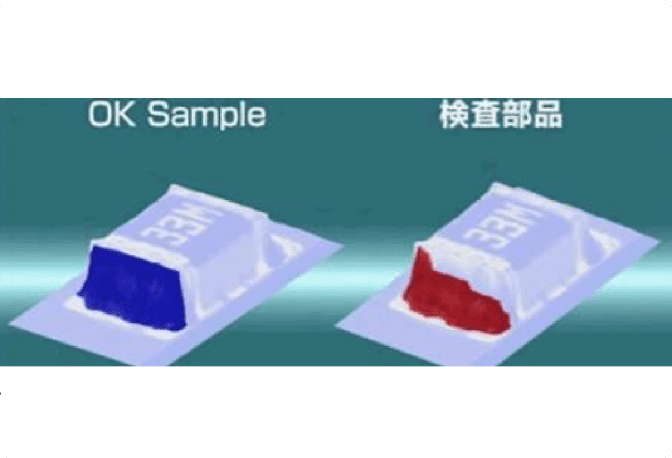

Inspection process

This is the process of inspecting the completed PCB. The 3D shape of the completed PCB is analyzed by comparing shapes by the outlines, heights and luminosities of the components and solder. Each PCB is accepted or rejected based on the results. A 2D inspection function can also be applied.

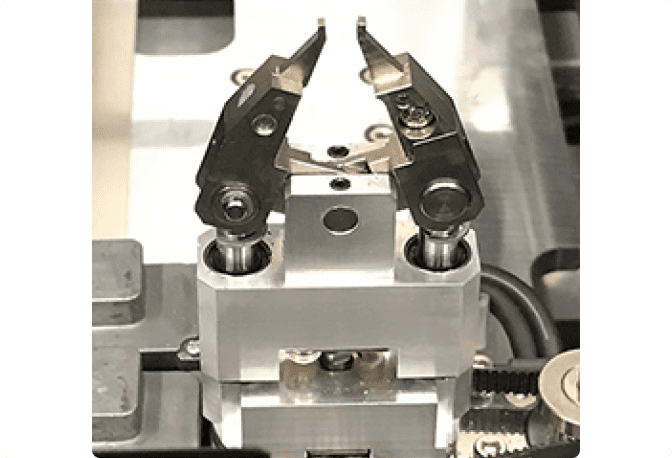

Insertion process for odd-shaped components

This is the process of inserting large or odd-shaped components that cannot be placed in the conventional surface-mounting process. The standard-spec components that can be placed with a chip mounter are stored on reels, while the components with complex, irregular shapes are delivered in bulk in bags and mounted using the odd-shaped component insertion machine.

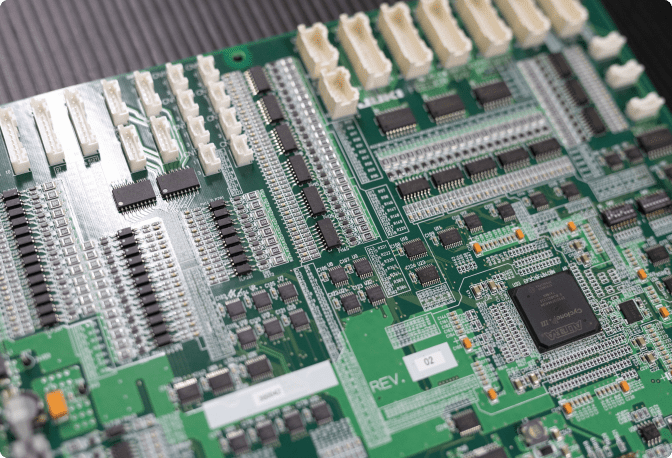

Completed electronic circuit boards

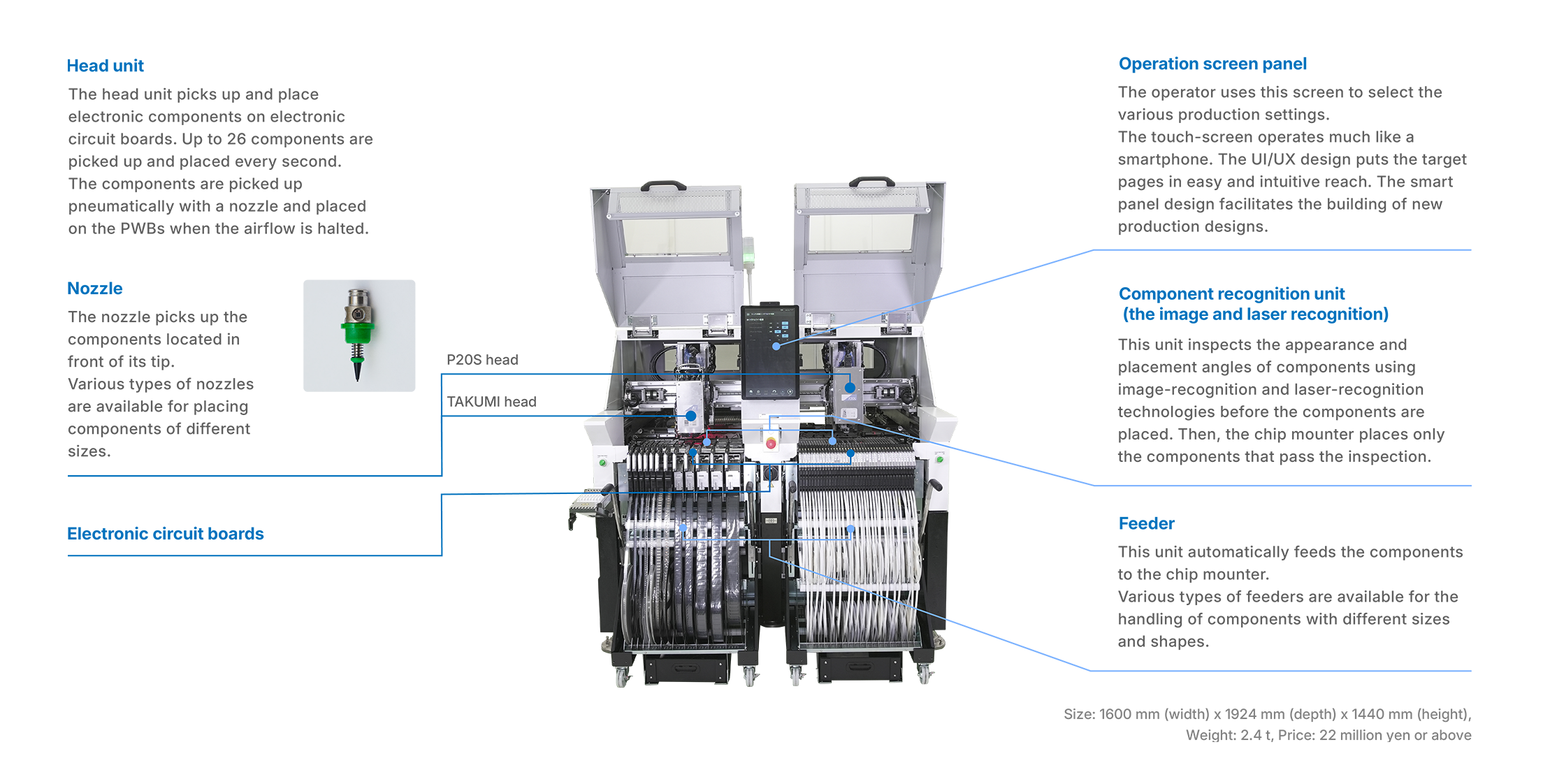

“Chip mounters” in a nutshell (illustration)

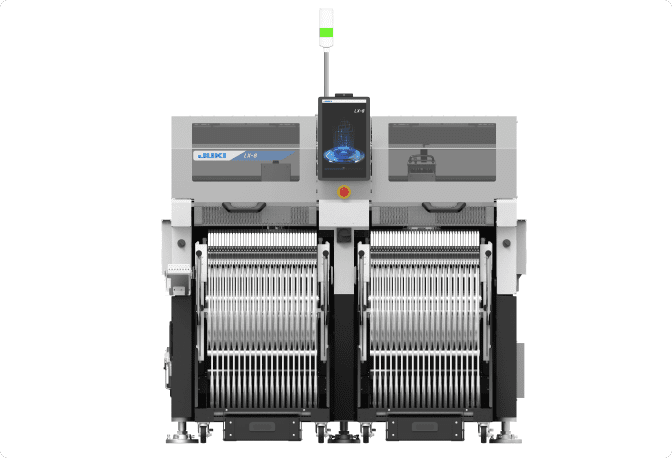

This section introduces the High-speed, Flexible Mounter LX-8, one of JUKI’s chip mounters.

The LX-8 is another JUKI mounter for the placement of electronic components on the PWBs. The LX-8 is a new concept mounter that allows the flexible combination and replacement of two different types of head (the high-speed, high-precision P20S head and high-speed, general-purpose “TAKUMI head”) in a single standalone machine.

High-speed, Flexible Mounter LX-8