Production of Household Sewing Machines

Production sites for household sewing machines

JUKI (VIETNAM) CO., LTD., the mother factory for JUKI’s household sewing machines, produces JUKI’s major household machines such as its models for computer-controlled sewing, overlock sewing, and professional sewing applications. The factory has delivered reliable quality and satisfaction to customers since its establishment in July 1990.

Examples of products

Kokochi DX-4000QVP

Haruka TL-18QVP

Akane MO-3000QVP

How a household sewing machine is completed

1Frame machining

In this process, surfaces are cut and screw holes are machined in an aluminum alloy frame. Computer-programmed machining (a numerically-controlled machine tool) ensures that the processes take place with high accuracy and speed.

Parts machining

The axis-related machining is performed by automatically switching several cutting tools through a programmed sequence.

Automated transportation

Once the machining is completed, an AGV transports the frames to the assembly line according to the production plan.

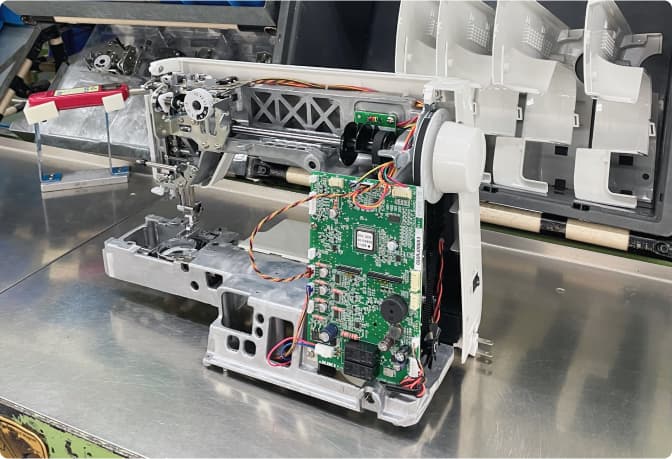

2Assembly

Once several parts are machined, the drive motor, thread trimming unit, etc. are assembled onto the frame. To prevent assembly errors, the assembly procedures and necessary parts are planned out and produced according to product specifications and drawing requirements. The workers overseeing these steps acquire multiple skills through in-house training.

Assembly of a household computer-controlled sewing machine (HZL line)

A household computer-controlled sewing machine is completed by attaching parts, plastic covers, and other components to an aluminum casing frame.

As many types of household computer-controlled sewing machines have to be produced, JUKI adopts a mixed flow production system in which several types of machines are assembled on a single line through “high-mix, low-volume production.”

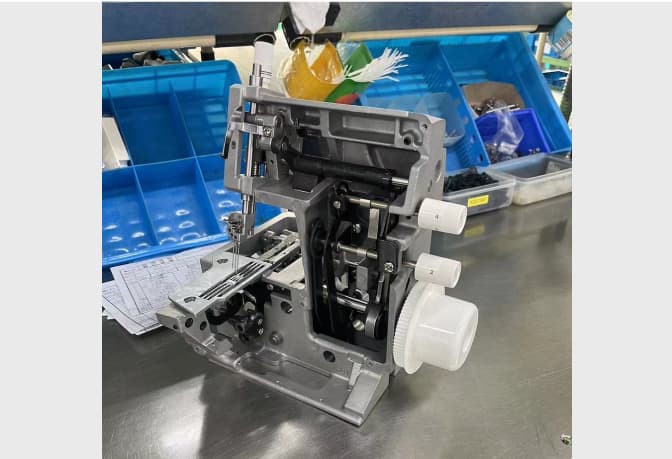

Assembly of a professional sewing machine (TL line)

After the frame is machined, the arm and bed are joined and then sent on to the assembly phase. After the parts are attached to the joined arm and bed, the top cover is attached to complete the assembly process.

JUKI’s “mass-produced models” for professional use are assembled using an “automatic conveyor production” method. A conveyor transports the machine to the next process at a specific takt time. The assembly is paced to match the time allotted.

Assembly of a household compact overlock sewing machine (MO line)

A household compact overlock sewing machine is completed by attaching parts, plastic covers, and other parts to an aluminum casing frame.

For difficult-to-assemble products such as sewing machines with an automatic thread tension function, JUKI uses a unit production system with a small team of 3 to 4 workers.

3Inspections

Process inspection

Precision inspections are performed under a variety of conditions in accordance with design requirements.

The objective of these inspections is to ensure that each product meets the required quality standards.

Pre-shipment inspection

Inspectors certified in-house strictly inspect the finished products.

The inspection records are digitized and managed to ensure that defects can be easily traced.

4Packing and shipping

Each machine is automatically packed and shipped to domestic or overseas sales bases. An electronic camera photographs the shipping condition to prevent any omission of standard accessories supplied with the machine.