Industrial Sewing Machinery Business

JUKI’s industry-leading sewing machine business

ProductsRepresentative products

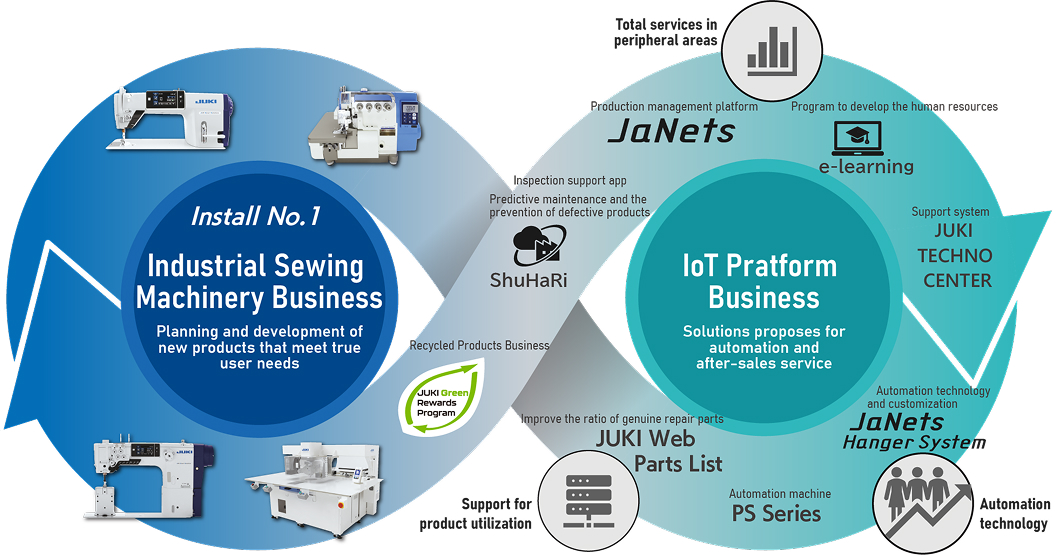

Providing business solutions with versatile products and services to support the growth of sewing factories

We support the world's sewing industry by sewing products in every field, from trendsetting maison brands to casual apparel, sporting goods, car seats, and more.

We provide a solution to every type of challenge a customer may face by integrating wide-ranging industrial sewing machines with IoT devices that automate processes, save labor, and visualize production management.

Taking the initiative as a platformer offering total support to sewing factories

The sewing industry is expanding to all parts of the world. The business environment is dramatically changing. The sewing industry faces various challenges within this evolving landscape, especially with regard to labor-saving, automation, and the reduction of environmental load.

JUKI provides customers with higher value-added solutions by combining its existing industrial sewing machines sales business with IoT technologies in automation, systems, and services. Through this integration, we expand from the sale of sewing machines (“products”) to the delivery of “services” that improve customer productivity and solve customer challenges.

As a platformer with a No. 1 market share in industrial sewing machines, JUKI provides total supports and eco-friendly products to sewing factories along with valuable business services that improve customer productivity and sewing factory environments.

These solution activities support the growth of sewing factories and promote sustainable business and social growth by driving the recycling model of “clothing” forward and helping create a decarbonized society and recycling-oriented economy.

Features and strengths of the business

1Providing the equipment for production control, automation, and production on a customer-by-customer basis

Customer factories differ not only in the products they produce, but in the layouts and equipment, the production plans, and many other parameters. The customer data accumulated on the platform is used to provide tailored production control systems, automation equipment and production equipment that respond to the unique challenges and goals of every customer.

2Deploying automatic machine lineups to automate a wide array of production processes

The shortage of manpower and skilled personnel in sewing factories is boosting the need for automation and labor-saving solutions. JUKI’s diverse lineup of automatic machines can handle a wide range of sewing items and sewing processes.

In the “Pattern Seamer” series in particular, we offer single machines that flexibly integrate JUKI’s original mechanisms, peripheral devices, and dedicated templates into sewing processes linked intelligently with robot transfer machines.

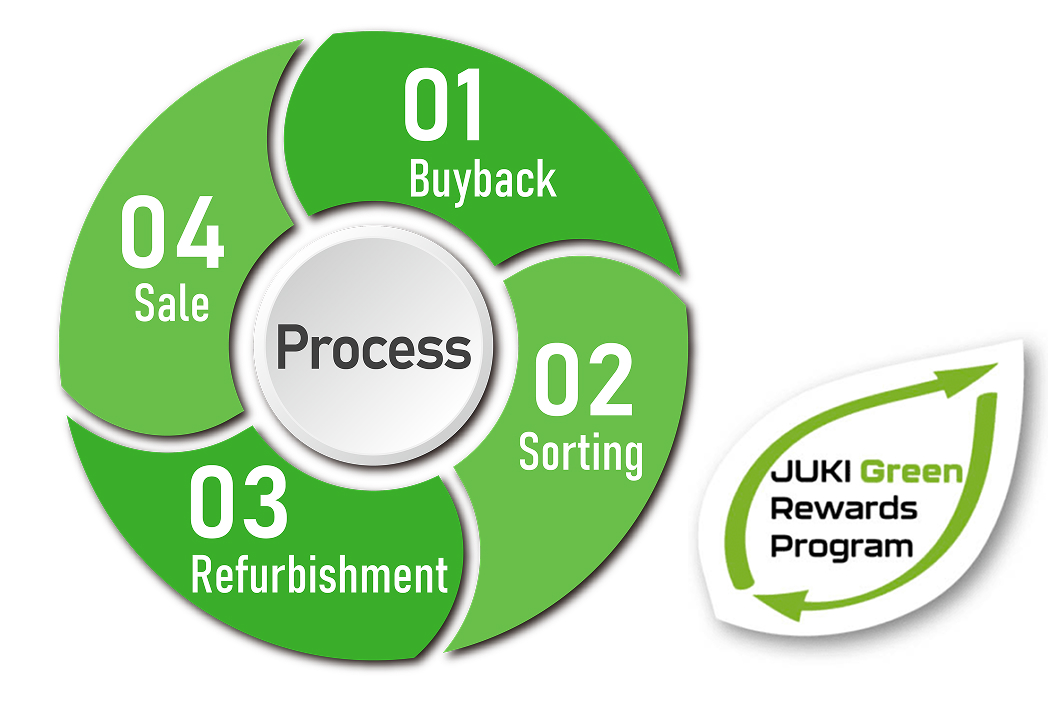

3Reducing environmental load with refurbished products

Under the “JUKI Green Rewards Program,” we use JUKI technologies to refurbish industrial sewing machines and electronics assembly & systems our customers have used and sell them as “refurbished products.”

Our refurbishment business promotes the creation of a recycling-oriented economy and the achievement of carbon neutrality by visualizing product life cycles and softening environmental load through reduced product disposal.

4Providing solutions from both hardware and software perspectives on the JUKI-ShuHaRi as a platform

The "JUKI-ShuHaRi" sewing machine inspection support system supports daily inspection and maintenance in sewing factories with a smartphone app and PC browser-based app to extend the sewing machine’s lifetime and reduce both downtimes and failure incidents.

JUKI-ShuHaRi also links with the JUKI Parts List to give customers instant access to spare parts found to be necessary in inspections. The services and supports customers receive from JUKI equipment and systems are backed by a repository of customer data accumulated over many years.

5Providing education programs based on abundant knowledge and experience

JUKI provides industry expertise in sewing machine maintenance and productivity improvement, along with management personnel training programs developed over the years in both face-to-face education workshops and e-learning courses.

With the e-learning capabilities now enabled, trainees can take advantage of JUKI’s education and training services from any location.

6Providing a vast selection of items and solution parts based on JUKI industrial sewing machines, the global market leader

JUKI products are chosen by many thousands of customers and distributed throughout global markets. To avoid production stoppages and ensure timely parts delivery in the event of machine breakdowns in factories, JUKI has set up a parts supply system with approximately 100,000 kinds of industrial sewing machine parts in stock.

In addition to spare parts, customers can acquire solution parts that can be relied upon to enhance both productivity and quality.

Manufacturing and sales bases and main sales offices handling JUKI industrial sewing machines