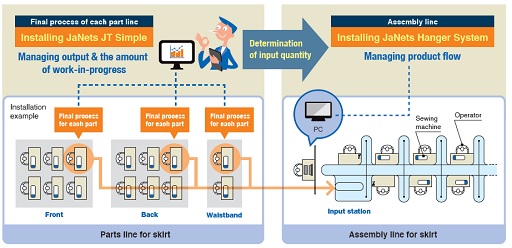

Propose JUKI’s Smart Hanger Solution by Connecting with JaNets

Line progress management by connecting JaNets Hanger System with JaNets, makes higher productivity than sitting operation!

Effects/benefits

For customers considering installation of hanger system

Hanger system is a production system which transports products to the sewing station on hangers.JUKI offers the most suitable hanger system considering sewing items and factory facilities.

●The automatic conveyor system reduces the amount of work required to pick up and dispose the products, and is expected to result in higher productivity than conventional sitting production.

●Each hanger is equipped with RFID for traceability of product number, color, size, and work-in-progress position.

●The use of operator IDs makes it possible to get data for each operator.JaNets Hanger System installation proposal

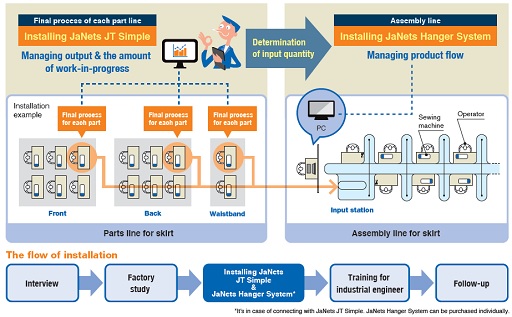

The input amount for the assembly line can be examined based on the parts output managed by JaNets, preventing delays in the input of parts for the assembly line!

Product features

Visualization with JaNets!

Production progress of hanger lines can be obtained in real time from JaNets reports!

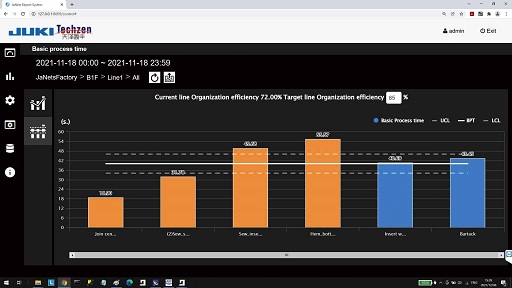

Basic process time

The logic developed for JaNets enables accurate basic process

time and line balance. Due to the line balance graph that takes

into account multiple tasks, and makes it possible to accurately

find the bottleneck processes regardless of the amount of

hangers in use.

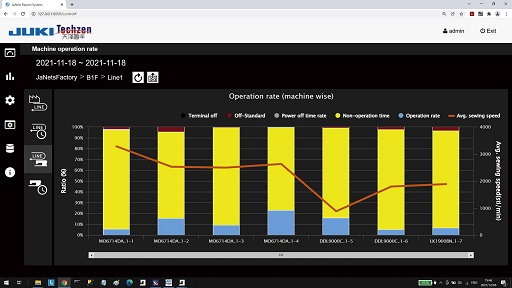

Operation rate

By connecting with JaNets, you can see the equipment’s

operation rate and check whether each equipment in the hanger

line is effectively utilized. It's possible to grasp the sewing skill

level of each operator. Downtime of each sewing machine can

also be monitored. This allows quick response to machine

breakdowns and minimizes production loss.

●Optional parts are required

Connection with JaNets!

The input amount for the assembly line can be examined based on the parts output managed by JaNets, preventing delays in the input of parts for the assembly line!

Basic performance

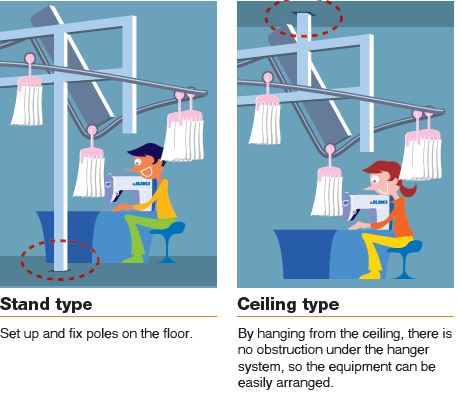

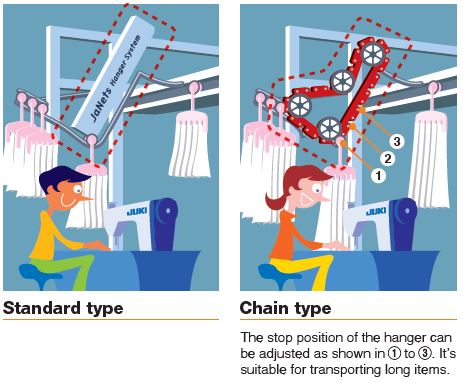

Each can be freely combined

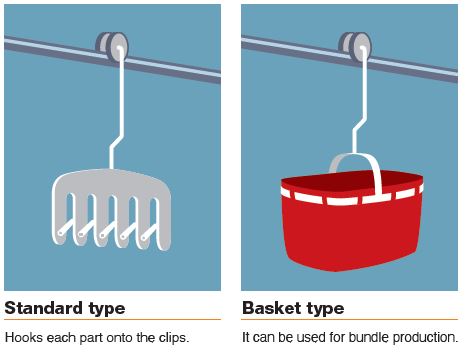

Possible to combine installation methods, stations, and hangers freely.

Installation methods

Stations

Hangers