The Story Behind the Development of JUKI’s Semi Professional Sewing Machines

How the SL-700EX — Recipient of the LONG LIFE DESIGN AWARD 2023 — Became Japan’s Standard Semi-Professional Machine

Since its founding in 1938, the JUKI Corporation has been devoting itself to advancing “monodzukuri” (the art of manufacturing) through its seven arms: the Industrial Sewing Machinery Business, Household Sewing Machinery Business, Electronics Assembly & Systems Business, Contract Business, Storage Business, IoT Platform Equipment Business, and Customer Support Business.

A wide range of sectors is supported by our technologies, including fashion (clothes, shoes, bags, etc.), non-apparel (car seats, air bags, etc.), and high-tech devices using circuit boards (smartphones, medical equipment, etc.). Serving customers in 185 countries, JUKI is committed to continually advancing the technologies stemming from its sewing machine business, with the goal of improving the quality of people’s lives and supporting industrial development.

In 2023, the SL-700EX semi-professional lockstitch sewing machine became one of the recipients of the LONG LIFE DESIGN AWARD. To be eligible for the award, the product has to provide features and consumer value that are widely acclaimed for more than 10 years, and receive feedback from customers indicating their hope that the product will continue to exist for many years to come. In fiscal 2023, only six out of 104 eligible products — including JUKI’s SL-700EX — had the honor of receiving the award.

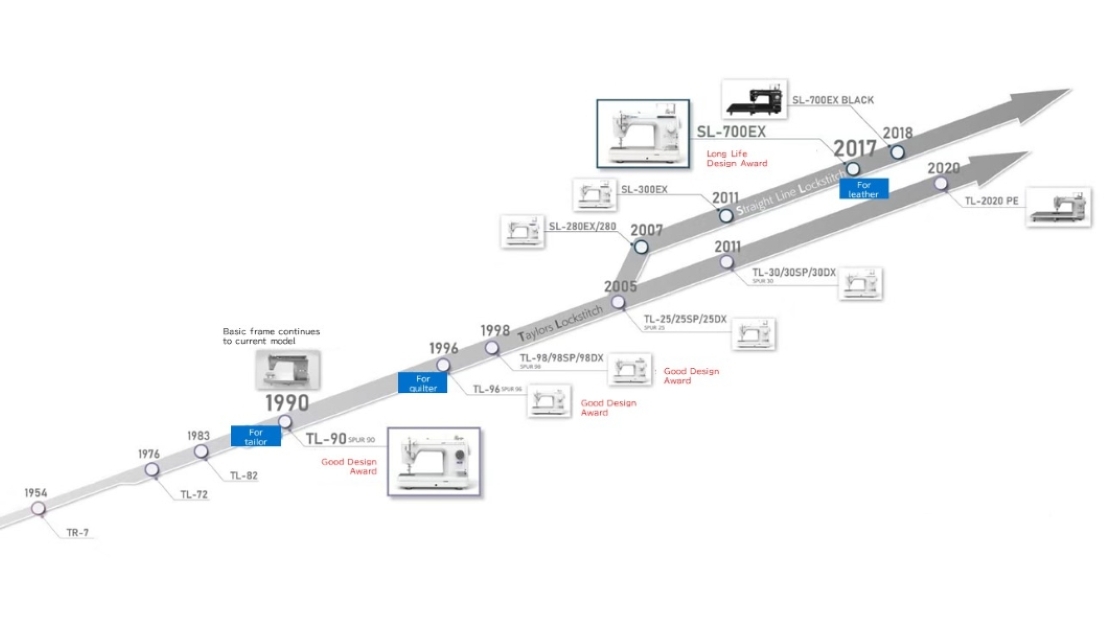

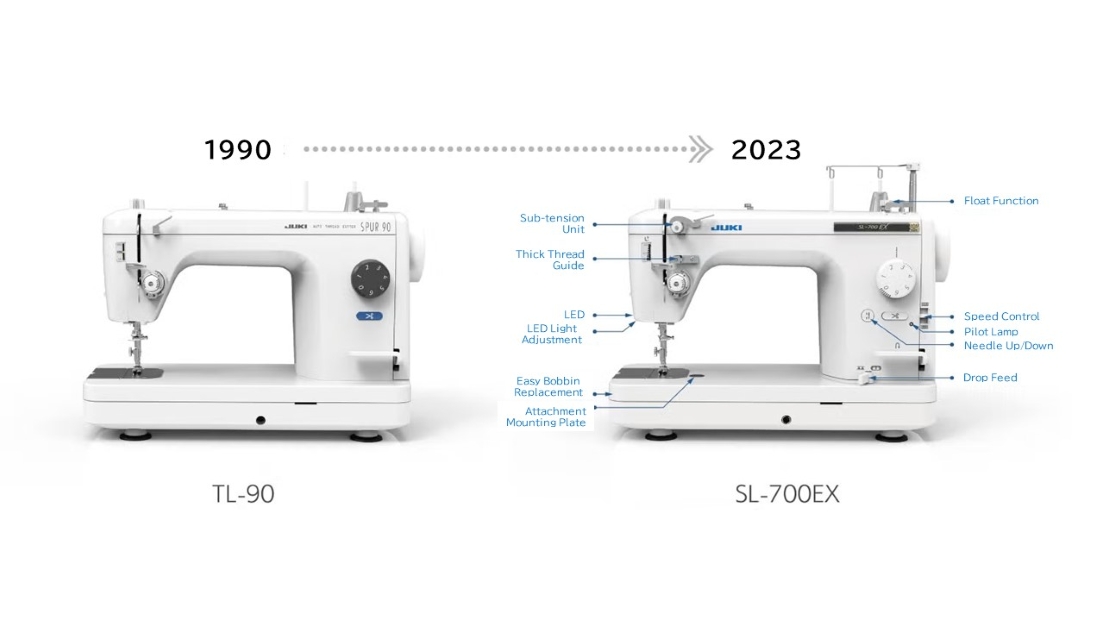

The design of the SL-700EX dates back to the TL-90, a semi-professional sewing machine launched 33 years ago. That model received continual upgrading of its many user-friendly features without changes to its basic shape.

The journey of the TL-90’s offshoot — the SL-700EX — demonstrates JUKI’s commitment to expanding the horizon of the semi-professional sewing machine from “a machine exclusively for professional use” to “one used by general public.” Here is that story, supplemented by the words of the planner and the developer.

The Semi-Professional Sewing Machine Market and JUKI’s Involvement Up to the 1980s

Semi-professional sewing machines (a.k.a., semi-industrial sewing machines) were given that name because they were used by tailors who needed faster and more powerful machines for sewing made-to-order garments when ready-made clothes were not yet popular.

JUKI sold its first semi-professional sewing machine, the TL-7, in 1954, followed by the second-generation TL-72 in 1976, and the third-generation TL-82 in 1983. These early machines were made by casting iron in the same way as with industrial sewing machines, and were heavy, not easily movable, and looked “seriously professional.”

It All Began with the Launching of the TL-90 Semi-Professional Machine 33 Years Ago

In April 1990, JUKI launched the TL-90, which became the semi-professional sewing machine that expanded the benefits of such machines to general users. It also had a stylish look that was drastically different from its predecessors.

Recalling its development, which was in charge of planning the product, comments, “At that time, the demand for a lightweight, portable, semi-professional sewing machine was emerging. The demand was particularly high among the students of fashion design schools who were aspiring professionals, but at the time, JUKI had no such products to offer. Dealers also expressed high expectations that JUKI — as the world’s top manufacturer of industrial sewing machines — would produce semi-professional sewing machines.”

Against this backdrop, JUKI decided to tap into the market with the basic concept for their new machine being “lightweight, portable, equipped with industrial-machine-level technology, and having a stylish look.”

They add, “Because the concept was clear-cut, our development and design divisions accepted the proposal without any problem, and we were all set for the endeavor with a shared goal in mind.”

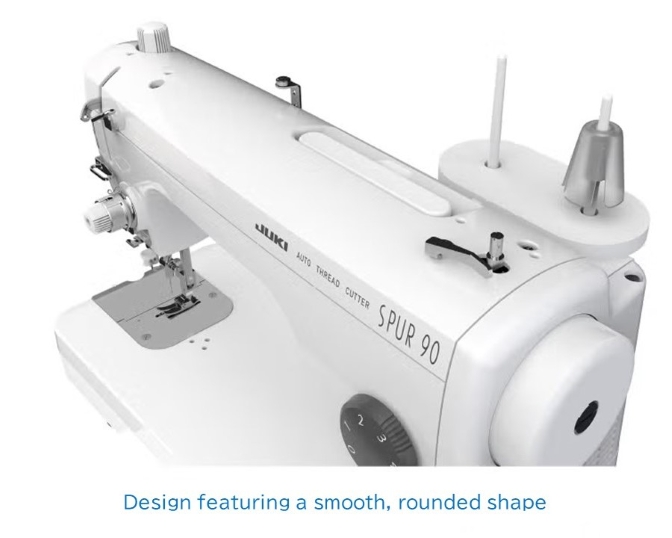

The design division was particular about the appearance of the new model. Some competitors used plastic materials to reduce their machines’ weight. JUKI, in contrast, created an aluminum die-cast frame for its light-weight structure, durability, and stability.

They say that the use of aluminum allowed JUKI to shape the frame precisely, and gave greater liberty to the designers. He recalls, “The TL-90 was aiming to achieve a smooth, rounded form, like the works of the impressionist Pierre-Auguste Renoir. However, for the machine’s overall form, we finally decided to keep it fairly standard rather than reflecting our personal preference. We wanted a large throat, not-too-tall body, a slim needle section with its face cover curving inward as it descends, and a bed shaped like the bottom of a ship. The controlling parts of sewing machines at that time had a mechanical appearance and were not well laid out, so it took time for sewers to get used to them, but the TL-90 nicely integrated these parts into its rounded body, making them easier to access.”

The most notable feature in terms of functionality was the first-in-the-industry automatic (push-button) thread trimmer which cuts top and bottom threads simultaneously when stitching is finished. Because the trimmer for industrial sewing machines did not fit the TL-90’s compact body, JUKI had to be creative in developing its new compact version in order to retain the key parts of the industrial version which ensured trimming quality. To achieve that, many prototypes were made and discussions were held.

The resulting product was the compact and portable semi-professional TL-90 with its light and stylish body, equipped with many functions on a par with industrial machines, which are designed to achieve strong material feeding and clean, firm stitches on both thick and thin materials.

They comment, “we toured around Japan in a car carrying the TL-90 and held new-product events for dealers. We were very happy to receive favorable feedback from the participants, who made remarks such as, ‘It’s a machine that surpasses our expectations.’ In the planning stage, we had had to set a sales target that was extremely high considering the market’s size and maturity, and JUKI’s sales. My hand was shaking when I entered the target figure into the proposal document.”

Despite grave concerns, the TL-90 performed very well, marking sales more than three times higher than the target.

Rave Reviews for Its Beautiful Stitches Led JUKI to Add Quilting to the TL-90’s Repertoire and to Tap into the Market of the Country of Quilters — the U.S.A.

Although the TL-90 made a big hit in Japan, tapping into the U.S.A.’s semi-professional sewing machine market was another story. To American users, the aluminum die-cast frame that was popular in Japan “looked cheap” and had a price tag too high for its appearance.

JUKI therefore had to give up on the U.S. market at first, but a few years later, the tide turned. American tradition has it that quilting is passed on from generation to generation — from mother to daughter, from daughter to granddaughter, and so on. American quilters were moving away from straight-line stitching and practicing free-motion quilting by moving the material around as if to draw a picture with the stitches. During a visit to the U.S., JUKI staff were astounded that American quilters were using their machines in this way, but they also thought, “Maybe our semi-professional machines can also succeed as quilting machines because they’re known for their beautiful stitches!”

In many sewn products, the stitches are hidden, but quilting is all about neat, clean stitches. The beautiful stitches of JUKI’s machines received favorable reviews from American quilters, which inspired JUKI to incorporate various features into its semi-professional machines that catered to quilters, and then to reenter the American market. As a result, JUKI’s products gradually gained greater recognition in the United States.

How the Ultimate Semi-Professional Lockstitch SL-700EX Sewing Machine Was Developed and Swept the Japanese Market, Achieving a 70% Share

In recent years, Japan has been seeing a growing number of craft enthusiasts selling their handmade bags, leather goods, and other handmade items on e-commerce sites. The SL-700EX was launched in 2017, in response to growing demand among these crafters for a machine which could handle thick materials, such as canvas and leather, and improve the quality and marketability of their products.

Yasushi Baba (Product Manager), who was in charge of planning the SL-700EX, comments, “we had no intention of changing the overall form from that of the previous model, because we had good user reviews. Instead, our approach for the new model was to keep the basic structure and add more features.”

The SL-700EX is equipped with many newly-developed and improved features to accommodate market needs. The challenge for this major renovation was how to incorporate new features that met market needs without changing the basic design.

The developer of the product, Atsushi Shiraishi (Product Development), says, “we had to further improve the machine — which was already capable of sewing both thick and thin materials — to make even thicker materials handleable. Achieving improved handleability of thick materials while maintaining clean stitches requires “fine tuning” of the machine, often at the expense of compromised operability. So, we decided to add a thread path dedicated to low-count (thick) thread so that its tension could be easily adjusted. JUKI’s semi-professional sewing machines had a time-tested reputation for operational simplicity and high-quality stitching, beginning with the first model — the TL-90. It was a real challenge to keep these advantages while finding a way to secure sufficient space for added features.”

To resolve the dilemma, members of the product development team had to have many discussions, including some heated ones, and devise new functions such as the “float function,” which allows the machine’s foot to move up (float) slightly to handle not only thick materials, but also to sew quilts and knits beautifully.

This function received big support from users. Other new functions, which were inspired by user input, include a foot controller with a thread-trimming foot switch, and LED lighting that allows light volume control. The crystallization of our members’ efforts, the SL-700EX, helped boost JUKI’s market share of semi-professional lockstitch sewing machines in Japan to almost 70% in 2020s, owing partly to a strategic promotional campaign using social media.

Aiming for Machines Even Friendlier to Users

In June 2023, JUKI launched the EB-1 buttonholer, which was the first-in-the-industry computerized buttonholer attachable to a semi-professional sewing machine. Because these machines are designed for sewing straight stitches, making buttonholes previously required hand-stitching, or buying a medium-range or high-end household sewing machine equipped with a buttonholing feature. Because of this situation, JUKI launched its EB-1 to meet the buttonholing needs of users of its sewing machines without that function, which was in high demand.

The highest hurdle to overcome was to make a buttonholer which could be retrofitted to a semi-professional sewing machine. It was a common practice for manufacturers to make new models compatible with a buttonholer, but JUKI took into account the needs of its existing users who had no buttonholer and made the device retrofittable, so that customers could continue to sew with their semi-professional JUKI machines.

The EB-1 was JUKI’s first retrofittable buttonholer and its development was challenging, to say the least. Shiraishi adds, “given the many complications, we had to come up with many proposals, make numerous prototypes, and test repeatedly before commercializing the product. How we approached the product’s planning and design was completely different from that of improving the features and performance of existing machines, and this new approach helped us re-discover the benefits of semi-professional machines. The project definitely increased my love of semi-professional sewing machines.”

Aspiring to be a Supporter of Hobbyists through Sewing Machines

Looking back, “machine sewing” has changed dramatically over the years. Before, it was part of everyday housework, and the sewing machine was simply a practical tool to make sewing easier. Today, it is also a means of pursuing one’s hobby, and a growing number of hobbyists are looking for ways to achieve quality stitching with professional tools. Successfully meeting these needs, JUKI’s machines have obtained the overwhelming preference of such users.

To cater to these proactive users, JUKI has been collaborating with sewing specialists of various genres and sponsoring dedicated sewing classes for each genre. Also, at hobby trade fairs and other shows, JUKI is providing opportunities for visitors to experience the joy of sewing at an advanced level. Moreover, we are building social media communities to support machine sewing enthusiasts.

JUKI aspires to be more than simply a company that sells sewing machines. Rather, we want to be a supporter of hobbyists in improving their skills and increasing their joy of sewing. We are committed to walking side-by-side with sewing enthusiasts who need professional tools to work with.

In closing, we would like to share a product review for the SL-700EX by one of the judges of the LONG LIFE DESIGN AWARD 2023: “When we think of sewing machines, JUKI comes to mind. Such an overwhelming market share didn’t result in complacency, and the company’s uncompromising pursuit of high-quality products is nothing but a testimony to Japan’s excellent monodzukuri. JUKI’s sewing machines are contributing significantly to elevating the level of Japanese manufacturing, especially in the apparel sector. The excellent reviews given to its high-quality products are coming not only from Japanese users but also from global customers, reflecting its tremendous worldwide influence on product quality in the apparel sector. Being selected as a recipient of the LONG LIFE DESIGN AWARD means that the product is not only of high quality, but is also recognized as a product loved by consumers over a long period of time because of its design. Keeping things simple, without excessive accessories and overdone taglines, the company’s confidence and commitment to quality products is clear in its policy of unswervingly providing just those functions needed for each product. I hope to realize a world where this type of design continues to receive recognition.”