Production Capacity

The principle behind “made by JUKI” manufacturing is to strictly guarantee that “100% of JUKI products meet high standards of quality.”

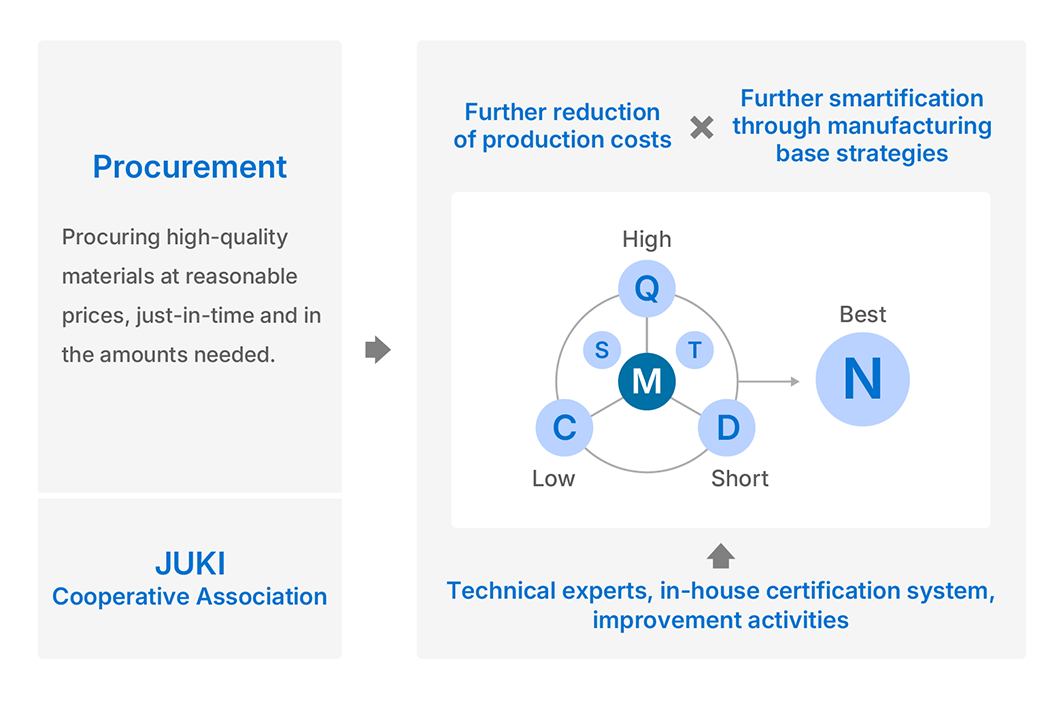

JUKI’s “manufacturing (MONODZUKURI)” capabilities continue to evolve through the adoption of global production strategies and DX (Digital Transformation) and GX (Green Transformation) factory systems that vertically integrate core production processes from casting and processing to final assembly.

The evolution of JUKI manufacturing is based on “six production elements”: <Q> Quality, <C> Cost, <D> Delivery time, <S> Safety, <T> Training of personnel, and

In parallel, JUKI combines production techniques from all of the manufacturing companies within the JUKI Group to enhance manufacturing efficiency. This is achieved not only through automation and robotization, but also the digitalization of manufacturing data and expertise. These efforts, in combination, promote powerful change in JUKI’s manufacturing sites.

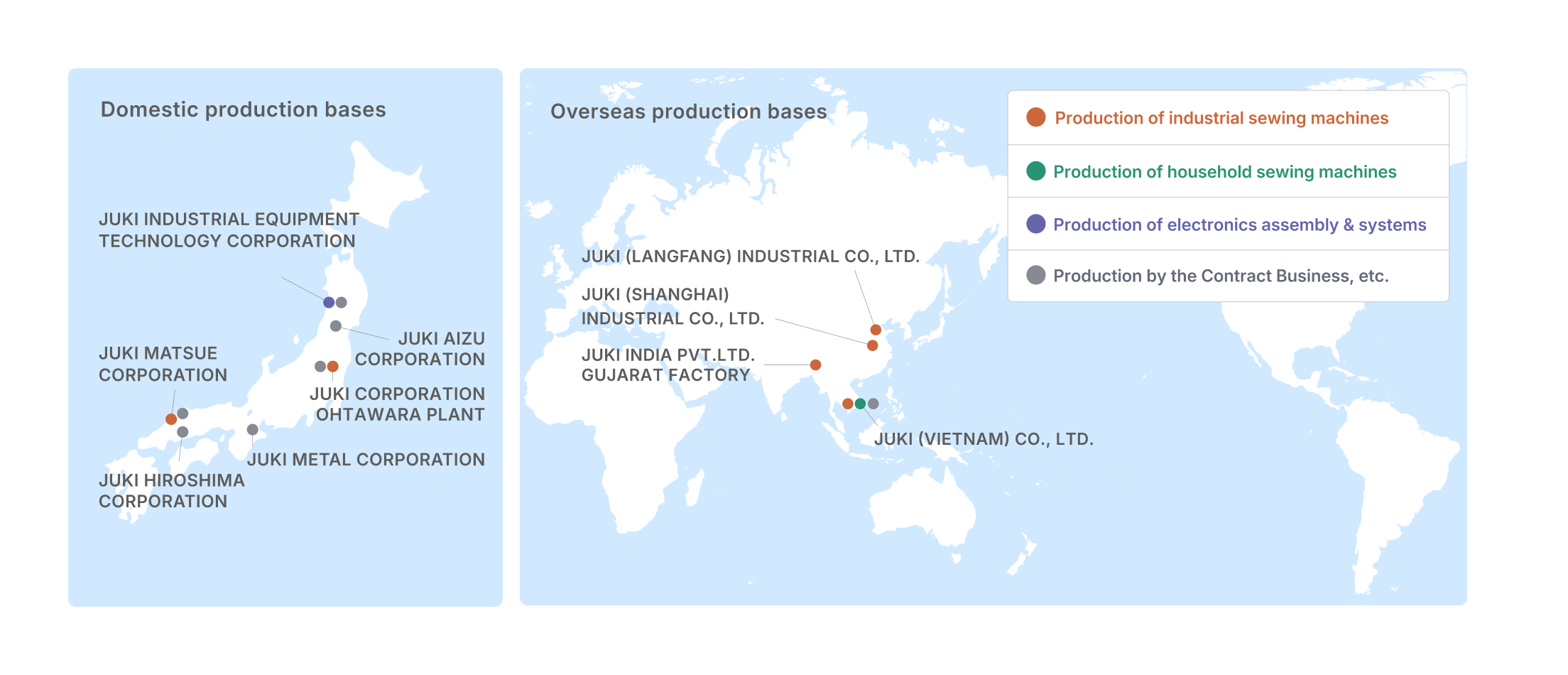

Global production strategies

JUKI industrial sewing machines are manufactured in Japan, China, Vietnam and India with a view to “manufacturing near customers.”

As a defense against supply chain disruptions aggravated by geopolitical risks, JUKI adopts parallel procurement and production systems with global reach for its most important models. These systems minimize risk and ensure that JUKI’s manufacturing operations adapt swiftly to market fluctuations.