Storage Business

Deploying automated warehouse systems in many different industries

Automating the inventory management of parts and small articles and their entry and dispatch to and from the warehouse

JUKI continues to broaden the scope of use of “automated warehouses” for the storage and management of electronic components by providing customers in multiple industries with automated warehouse systems customized for the management of manufacturing plants, high-value materials, and commodities.

Many businesses nowadays face daunting labor shortages, escalating demands for optimized efficiency, and similar challenges. JUKI supports them as a provider of automated warehouse systems that enhance efficiency in the management of parts and items.

Features and strengths of the business

1Diversified parts and items can be easily stored.

JUKI’s automated warehouse automates the inventory management of parts and small articles and their entry and dispatch to and from the warehouse. Variations in the types of parts and parts sizes can be easily accommodated by switching the storage trays.

The automated warehouse saves space by allowing for storage without spatial gaps. The equipment also prevents the intrusion of dust, enables storage at low temperatures, and ensures the security of the stored assets. Bar-code management enables the removal of the required part or item from a large inventory with pinpoint accuracy.

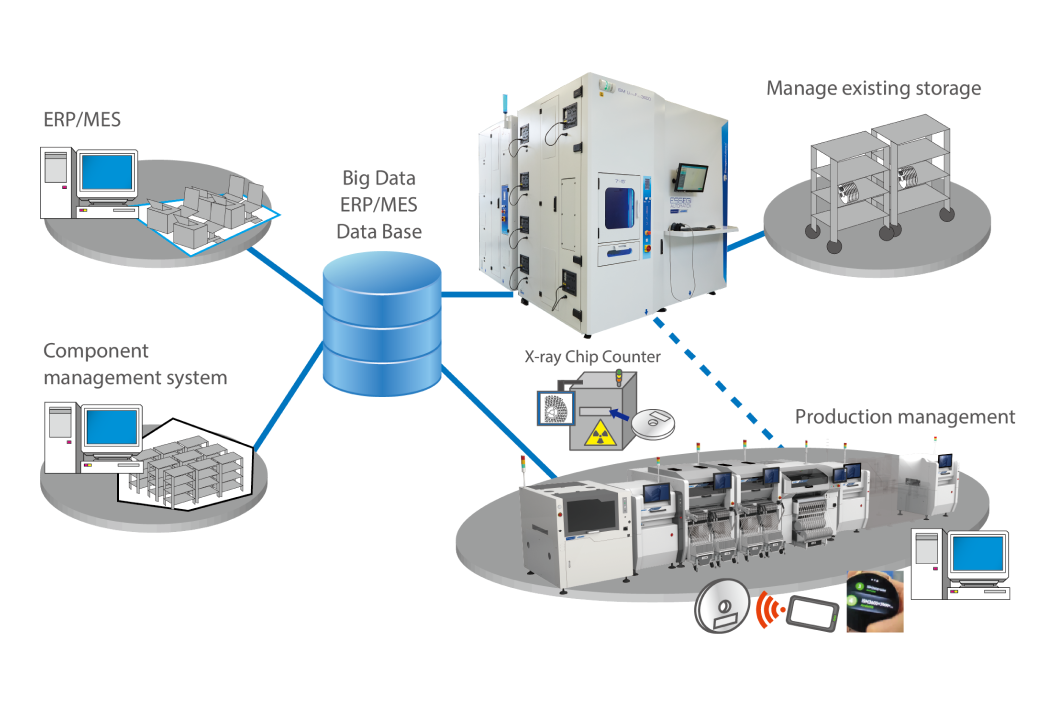

2Promoting the efficiency of inventory management through linked systems

The automated warehouse can be linked with the ERP (Enterprise Resources Planning) and MES (Manufacturing Execution System) functions via IoT to enable timely entry and dispatch of parts and small articles to and from the warehouse and their real-time inventory management in cooperation with the production sites. It can also be linked with AMRs* and picking robots to further automate transfer operations.

-

*

AMR: Abbreviation for Autonomous Mobile Robot

3Collaboration with automated warehouse manufacturers

JUKI has invested in ESSENGI AUTOMATION S.r.l, an Italian automated warehouse manufacturer with an advantage in the SMT field. The technical capabilities of the two companies in the planning and development of automated warehouses will be integrated to strengthen all facets of the business collaboration covering manufacturing, sales and service.

And based on the technologies cultivated in the SMT field, JUKI is trying to expand the geographic coverage of its automated warehouse business to serve the many industry segments experiencing labor shortages.