Electronics Assembly & Systems Businesses

Businesses that provide equipment and systems to support the automation of production lines

ProductsRepresentative Products

Total Solutions to Support PCB Mounting Factories

The JUKI lineup consists of not only the equipment for manufacturing the PCBs, but also all of the equipment required for the pre- and post-processes of the equipment. The all-encompassing functionality of the lineup guarantees the smartification of the whole of the customer’s production floor. JUKI provides “total support” towards optimal productivity of the entire production floor. With the help of forefront technologies such as IoT, M2M, and AI, JUKI equips factories with “production visualization” systems by networking the equipment in the line. Real-time displays of production in progress and equipment operation status help factories evolve to higher levels.

Features and strengths of the business

1Mounter products to enable the creation of flexible lines

The general-purpose mounters and high-speed mounters used to place the electronic components on the PWB in the PCB mounting process for manufacturing the PCB are provided with two unique JUKI innovations: the TAKUMI Head technology and Planet Head technology. A wide range of components can be seamlessly placed, and joining lines can be swiftly created to suit the items in production. Flexible mounter lines can also be configured by combining mounters into various production types such as high-mix, low-volume or variable-mix, variable-volume.

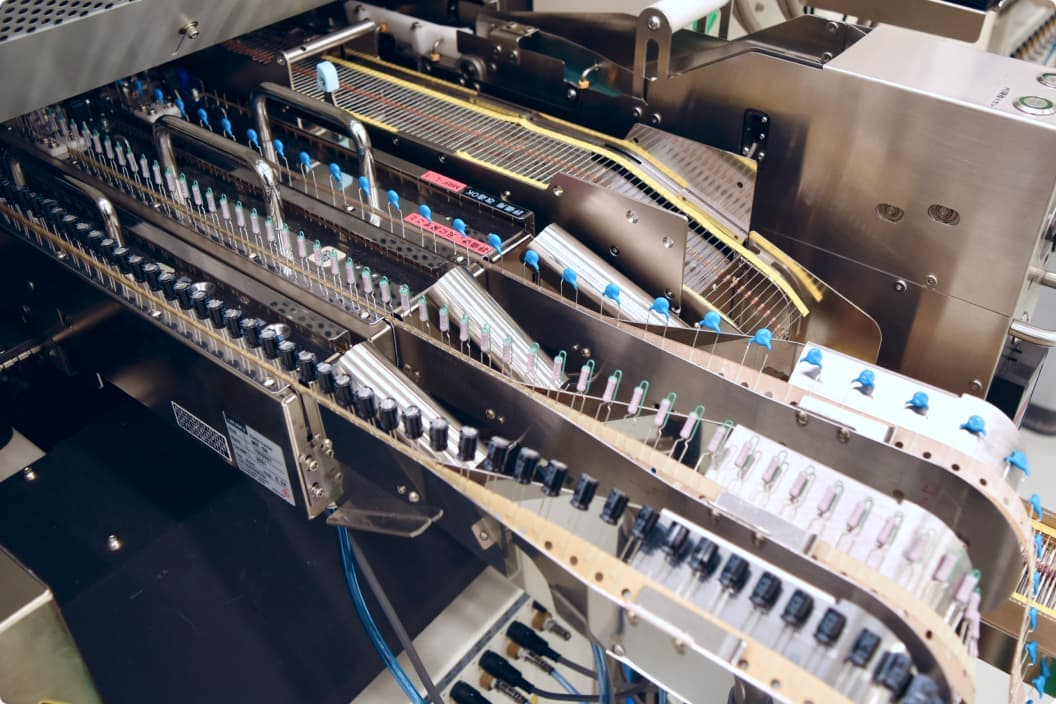

2Automation of manual insertion in the post process

JUKI has a lineup of odd-shaped component insertion machines that automate the manual insertion of components in the post-PCB mounting process. JUKI was the first company in the industry to embark on a project to research and develop insertion machines of those types. The resulting machines have now earned an impeccable reputation for insertion speed and quality. JUKI’s insertion machines powerfully facilitate the automation of the entire production floor.

3System software that achieves full production control and dramatically improves the productivity of the entire production floor

JUKI builds system software that links equipment and systems together to visualize every step of production from component acceptance to the shipment of finished product. The total-solution support from JUKI improves the entire production process and optimizes productivity.

4Supporting PCB mounting factories

JUKI offers a preventive maintenance agreement to ensure that the customer will enjoy using their JUKI products for many years to come. JUKI has also introduced a remote support system staffed by skilled engineers to troubleshoot difficult-to-handle failures that cannot be solved by local maintenance personnel. Data collected by smartphones and smart glasses in the field is shared remotely in real time to put the halted line swiftly back into motion.

5Providing full customer support

JUKI offers customers a worldwide parts supply system and product training programs, both online and in-person, to prevent the halting of factory production due to product failures. Our other helpful services geared for customer peace of mind include consultations on production engineering support and the sharing of the latest technical information.

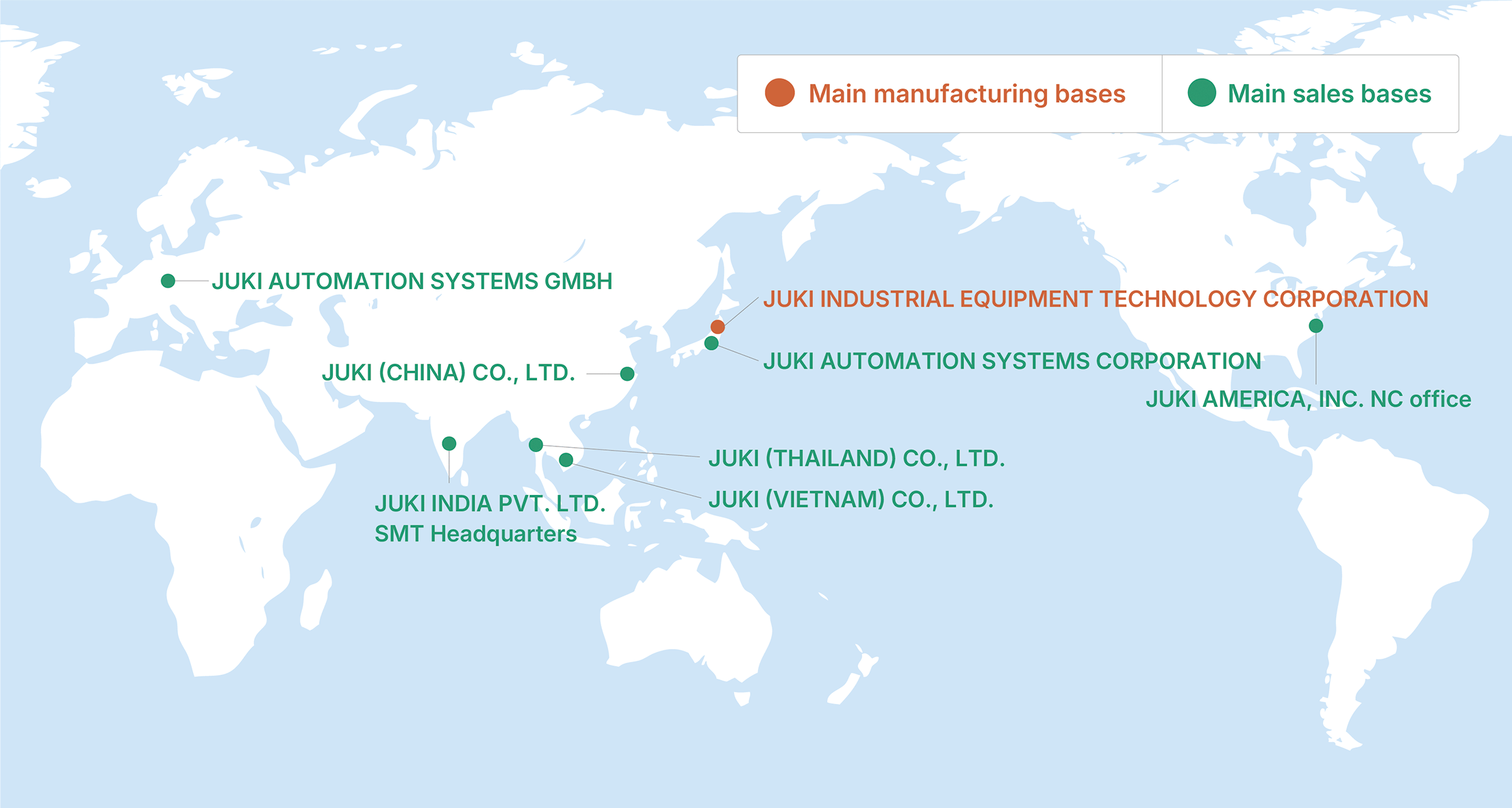

Manufacturing and sales bases for electronics assembly & systems