Contract Business

A business to support manufacturing companies through the collective strengths of “people, equipment, methods, and materials.”

JUKI supports customers engaged in the manufacturing business by backing them with its four collective strengths: “technician,” “development and manufacturing equipment,” “development and production know-how” and “materials.”

The Contract Business organically mobilizes and links the manufacturing capabilities of the manufacturing companies of the JUKI Group.

The manufacturing companies of the JUKI Group have development capabilities fostered through the design and development of JUKI’s major products (industrial sewing machines, household sewing machines, and chip mounters), the manufacture of parts, and the innovation of assembly methods. Their diverse, high-level manufacturing capabilities span from presswork to precision casting, and the manufacture of metal molds.

The factories of the Contract Business evolve their specialized manufacturing technologies to produce parts and products that respond to customer demands in manufacturing categories from optical equipment and OA/FA-related equipment to medical equipment and aircraft parts.

Features and strengths of the business

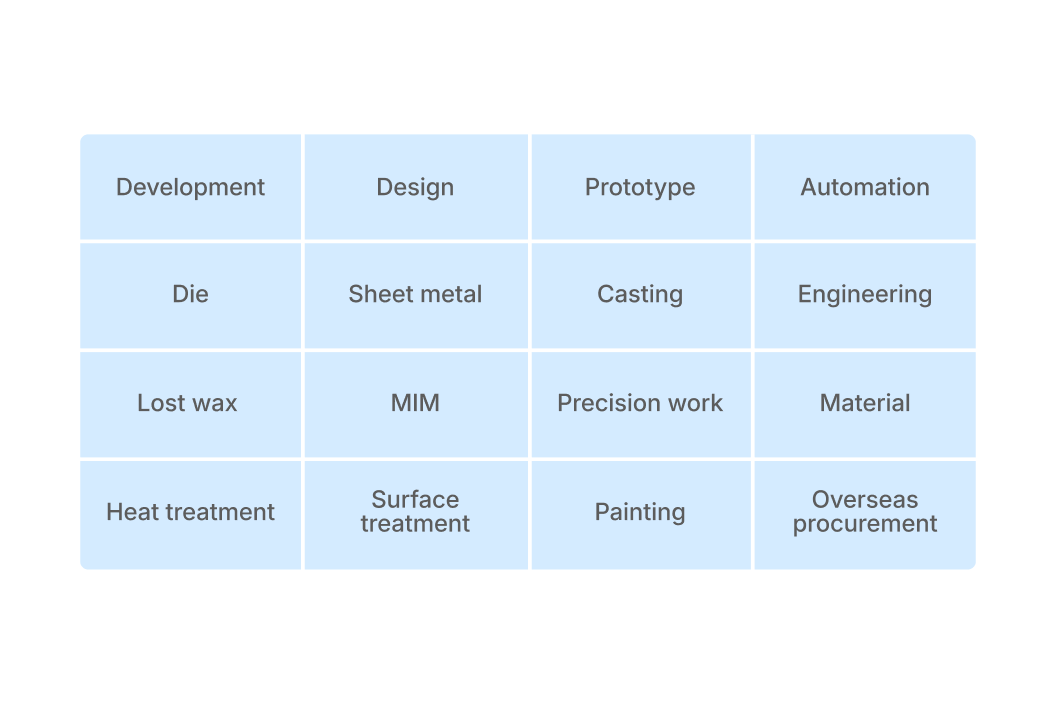

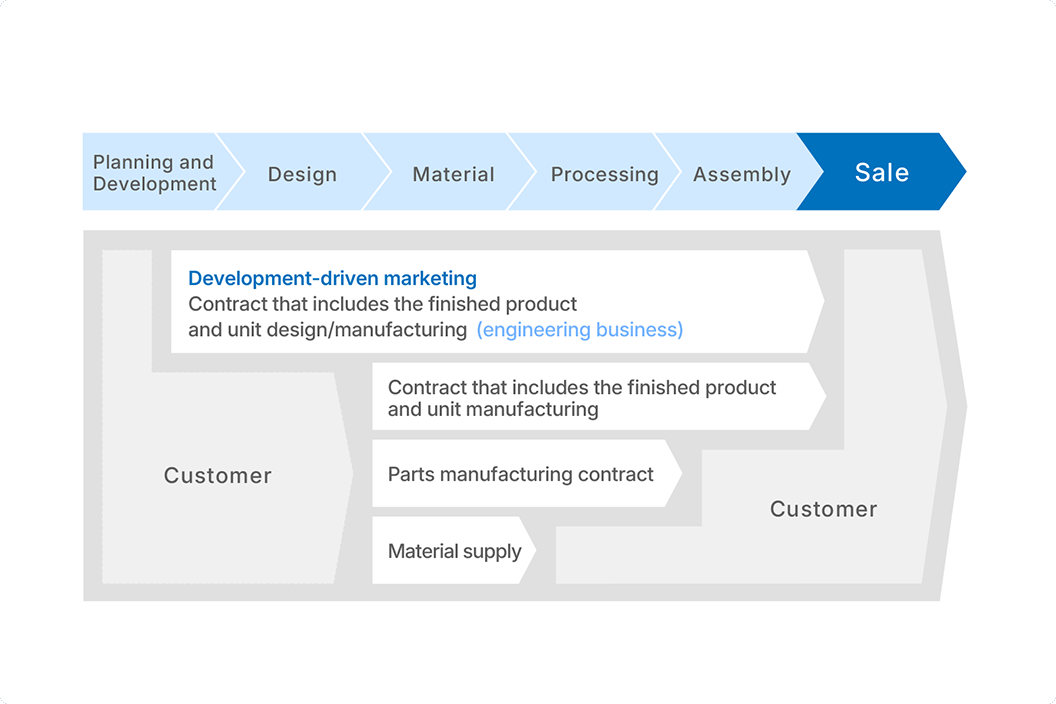

1Providing one-stop manufacturing services

The manufacturing companies in the JUKI Group possess all of the know-how and technologies that go into the different stages of manufacturing, from planning, development, design, materials, processing, and assembly to final inspection. The JUKI Group provides a “Multi-Select” manufacturing service that allows customers to select processes that fit their needs and a “One-Stop” manufacturing service that allows them to entrust all of the manufacturing steps from development through to production.

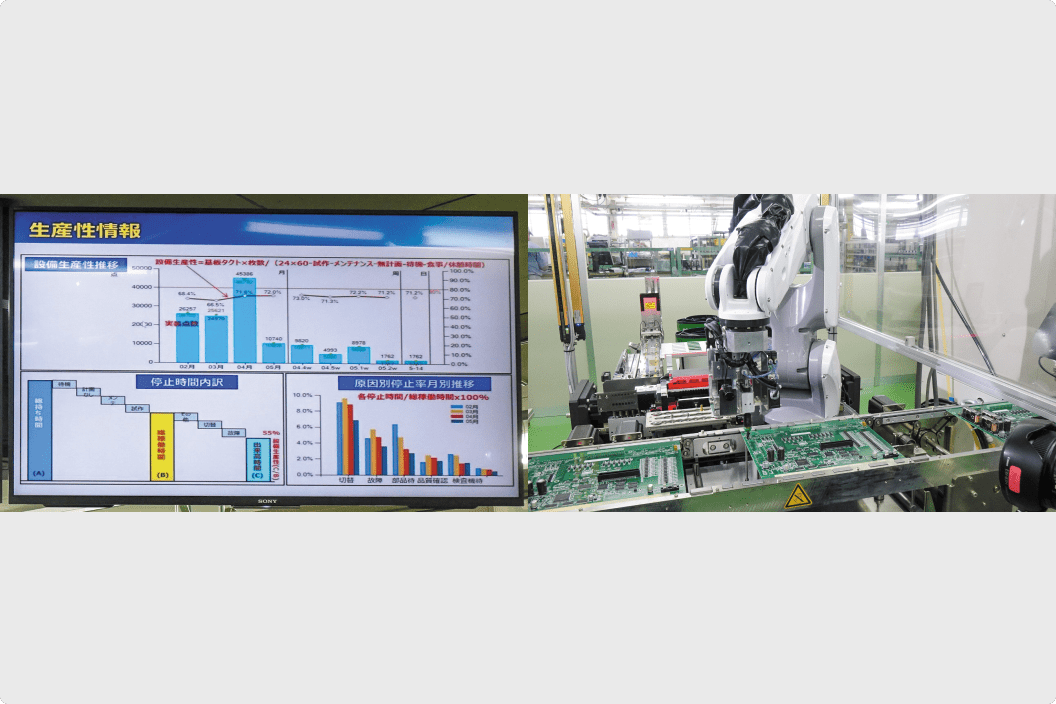

2Providing production automation equipment and constructing a production line (engineering)

Based on their experience with production technologies for the construction of manufacturing lines at their own factories, IoT deployment, and robotization, JUKI’s Group companies are entrusted with robotization of heavy labor, simple repetitive tasks, and the assembly of manufacturing line equipment at their customers’ manufacturing plants. JUKI can also solve issues from both hardware and software perspectives, such as challenges to overcome in line improvement and production visualization.

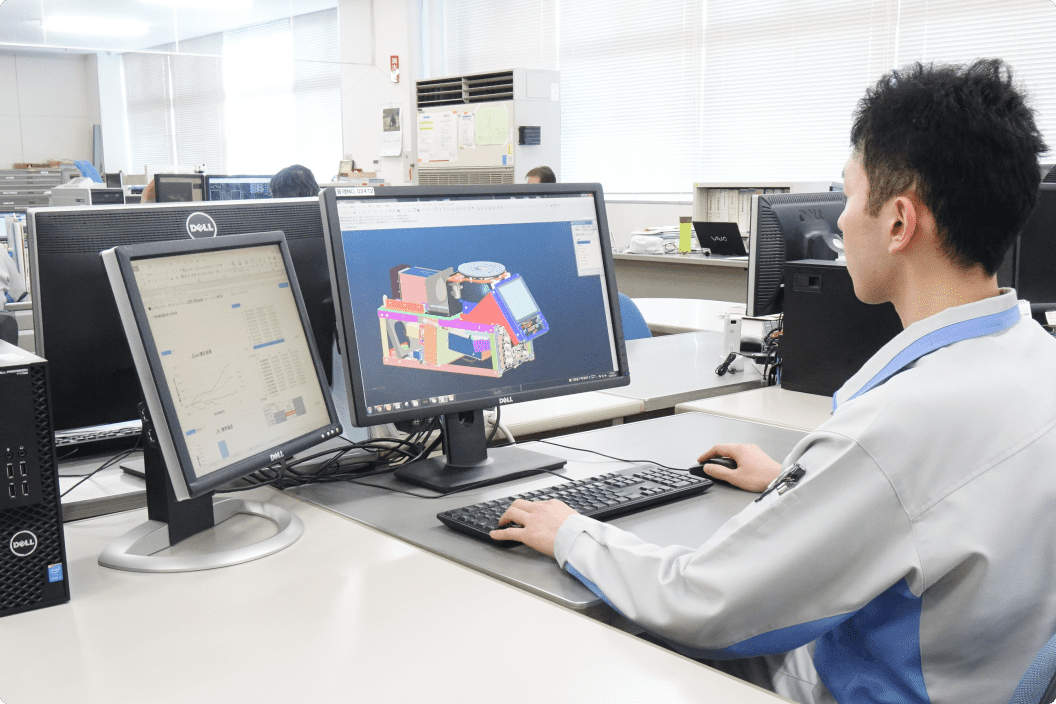

3Providing the design and development capabilities

JUKI Group companies engage in productization on behalf of customers based on their development capabilities in mechanics, electronics, and systems. Once development teams are organized according to the products or units they are entrusted to work with, the next step is to shape the demands from customers in various industry categories. In addition to offering outstanding design and development capabilities, JUKI Group companies support customers with manufacturing capabilities spanning the gamut from parts arrangement to the assembly of final products.

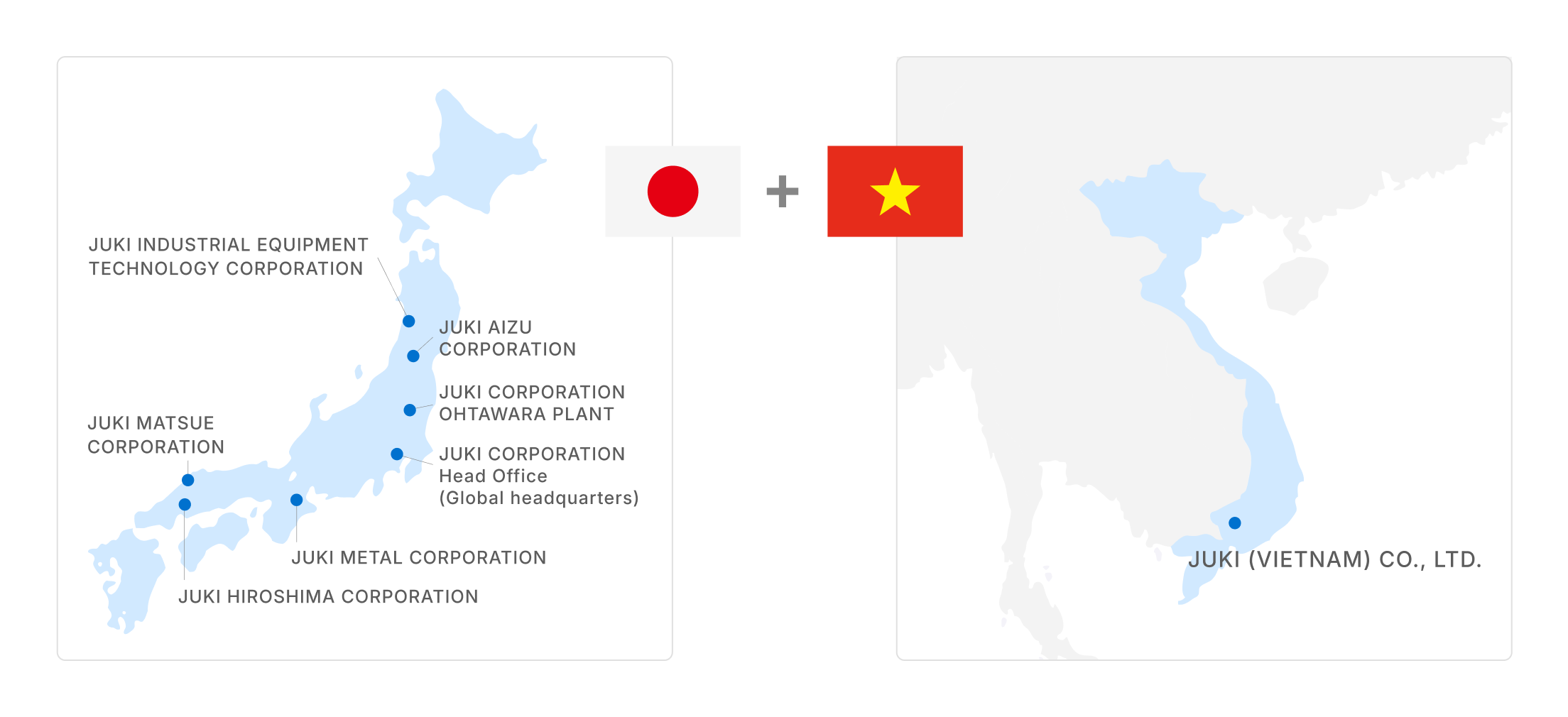

Collaboration bases

Dedicated website for contracted development and manufacturing

Dedicated website for contracted development and manufacturing