Improved seam quality through digitalization

The challenges facing sewing factories

Do you face any of the following challenges?

Shortages of labor and young applicants; the retirement of skilled workers and aging of maintenance personnel; difficulties in handing down expertise, training successors, and training employees; the need to boost operator motivation; the demand for the small-lot production of highly diverse products; the need to facilitate setup procedures, upgrade plant management, go paperless, stabilize quality, and simplify maintenance operations...

JUKI's digital solutions

JUKI can solve all of these challenges.

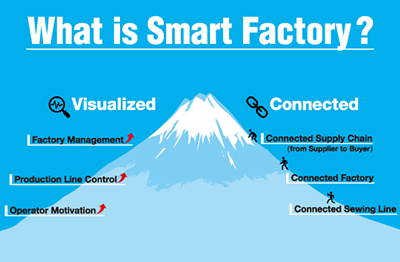

Let's aim to create a "smart factory" with JUKI!

What is a digital sewing machine?

Functions for adjusting seams can be digitalized and numerically stored in memory. The adjusted data can be saved on a tablet running the dedicated app and transferred to other sewing machines. Sewing-related adjustments that conventionally depended on operator intuition and experience can now be carried out in a few short seconds. Sewing data can be easily shared and managed. Quality is stabilized globally throughout the factory.

Features of digital sewing machines ~ For 1-needle, lockstitch machine DDL-9000CF ~

Digitalization of adjustments that formerly depended on operator intuition and experience.

The presser foot pressure and thread tension can be adjusted on the color touch panel.

See details here

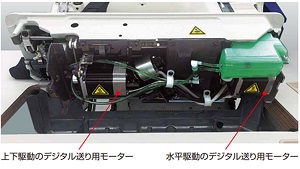

Double digital feed mechanism

Set the feed dog height and feed locus on the panel for streamlined adjustment!

A remaining thread length of 3mm is achieved at the end of sewing.

Active presser foot

The presser foot pressure is controlled digitally.

When sewing multi-layered parts of a material, the presser foot pressure is automatically raised or lowered by the multi-layered-part-detection function.

Active tension

Set the needle thread tension on the panel and save the set value.

Reproducibility contributes to shorter setup times when changing a product.

Digitalization of the control panel

The large, 4.3-inch color LCD touch panel dramatically improves operability.

The built in NFC (near field communication) function enables data transfer to and from Android tablets to enable on-tablet data adjustment.

Sewing / sewing machine management using the IoT (Internet of Things)

Download the sewing data set for sewing products from a sewing machine to an external medium such as an Android terminal or USB thumb drive.

Set the sewing machines on your line to identical settings and place them in the same status to stabilize quality and shorten the time required for setup changes.

Acquiring sewing machine data with the JUKI Smart APP

Data items such as management settings (registered on a terminal), sewing machine data (sewing data) and troubleshooting charts are provided. Use them to confirm the current state and analysis.

Example of DDL9000CF/CS Series at work

Example of JUKI Digital Sewing System DDL-9000C at work

Data saving and data transfer ensure reproducible sewing and the transfer of technology into the future

Direct-drive, high-speed, lockstitch sewing system with automatic thread trimmer DL-9000C Series

• Reduce the sewing machine adjustment time by transferring sewing data from your first sample sewing work to the production line.

Every operator gets the same sewing data, for highly stable quality.

• Needle thread adjustment, presser foot pressure, feed, etc. can be performed with a single push, making it easy to handle different materials.

• Skills are transmitted every time you convert sewing techniques into data.

Every time you transmit skills, you create a workplace environment where not only veterans, but also young operators can play active roles.

Example of JUKI Digital Sewing System LH-4500C at work

Programmed corner stitching improves productivity and stitch quality

Semi-dry head, 2-needle Lockstitch Sewing System

LH-4500C Series

• The corner stitching correction function improves quality by matching the stitch pitch at any angle.

• The lever on the hand side is all that’s needed for corner stitching, which promises improved operability.

• Save sewing machine adjustment values to shorten machine adjustment times when parts numbers change in small lot production.

• An 80% reduction in maintenance time leads to dramatic improvements in both the sewing machine availability rate and productivity.

Digital sewing machine lineup

DDL9000CF/CS Series

Direct-drive, high-speed, lockstitch sewing system with an automatic thread trimmer

LZ-2290CF/CS

Semi-dry head, digital zigzag stitch sewing system

LK-1900BN

Computer-controlled, high-speed, bar-tacking sewing system

LK-1903BN

Computer-controlled, high-speed, lockstitch, button-sewing system

LBH-1790AN

Computer-controlled, high-speed, buttonholing sewing system

MEB-3200C Series

Computer-controlled, eyelet buttonholing sewing system (with a trimmer for the needle and looper thread with a gimp)

MS-1261A/DWS

High-speed, feed-off-the-arm, 3-needle double chainstitch sewing system

(Digital Workstation)

AMS-221F Series

Computer-controlled cycle machine with an input function

PS-800SB-2850

Pattern seamer Sewing area 280 mm (X) x 500 mm (Y)

LU-2828V-7(1-needle)

LU-2860V-7(2-needle)

Semi-dry head, unison-feed, lockstitch sewing system with a vertical-axis large hook and automatic thread trimmer

PLC-2700V-7 Series

Semi-dry head, post-bed, unison-feed, lockstitch sewing system with a vertical-axis large hook and automatic thread trimmer

Other digital services

![]()

A sewing machine inspection support system that can be installed without extra cost.

A customer service department specialized in solving maintenance problems has been launched!

Easy daily inspections can now be performed with your smartphone.

Begin using the cloud service to perform easy maintenance processes for free.

JUKI SMART App

The "JUKI SMART App" is a free Android app that can be used with JUKI sewing system models.