Saving labor and improving efficiency through automation

The challenges facing sewing factories

Do you face any of the following challenges?

Shortages of labor and young applicants; the retirement of skilled workers and aging of maintenance personnel; difficulties in handing down expertise, training successors, and training employees; the need to boost operator motivation; the demand for the small-lot production of highly diverse products; the need to facilitate setup procedures, upgrade plant management, go paperless, stabilize quality, and simplify maintenance operations...

Automation by JUKI

JUKI can solve all of these challenges.

Let's aim to create a "smart factory" with JUKI!

Improving production capacity

AP-876

Automatic Pocket Setter

(For Jeans)

Deskilling

AE-200AN

Edge Control Seamer

Stabilizing quality

AMS-221F Series

Computer-controlled Cycle Machine with Input Function

Saving labor

APW-895N

(for straight pockets with flaps)

APW-896N

(for slanted pockets with flaps)

Lockstitch, Automatic Welting Machine

Manpower saving

PS‐910 Series

(Machine Head Rotation)

Machine Head Rotation Pattern Seamer

PS-910-13090

>See details

PS-910-6055

>See details

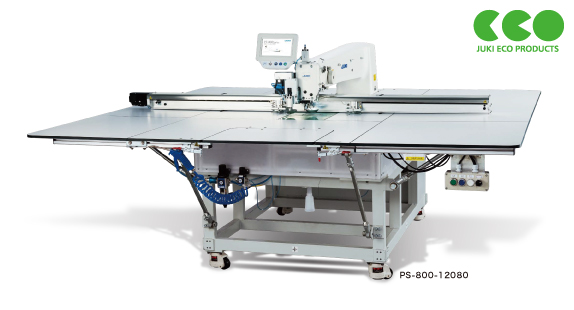

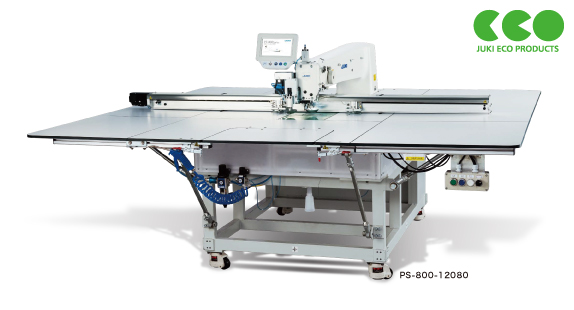

800 Series

(large size)

Pattern Seamer

PS-800 Series

>See details

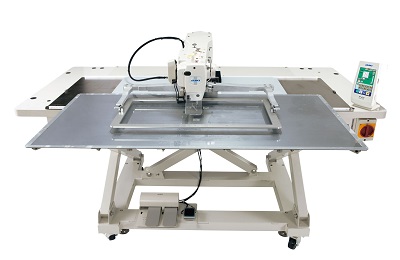

800 Series

(For small production lines)

Small size Pattern Seamer

PS-800-8045

>See details

PS-800-3830

>See details

PS-800SB-2850

>See details

Abundant lineup of automatic machines

Special-purpose machines

APW-895N (for straight pockets with flaps)

APW-896N(for slanted pockets with flaps)

Lockstitch, Automatic Welting Machine

>See details

AP-876

Automatic Pocket Setter (For Jeans)

>See details

AB-1351

Automatic 1-needle Belt-Loop Attaching Machine

>See details

AMB-289

Computer-controlled, High-speed, Single-thread Chainstitch, Button-neck-wrapping Machine

>See details

AC-172N-1790AN

High-speed, Computer-controlled Buttonholing Indexer

>See details

ASN-690 Series

Automatic Serging Machine

>See details

AE-200AN

Edge Control Seamer

>See details

Computer-controlled cycle machines

AMS-221F Series

Computer-controlled Cycle Machine with Input Function

>See details

AMS-210EN Series

Computer-controlled Cycle Machine with Input Function

>See details

AMS-221EN Series

Computer-controlled Cycle Machine with Input Function

>See details

AMS-221EN-HS3020/7200

Computer-controlled Cycle Machine with Input Function (for sewing pockets on jeans)

>See details

AMS-224EN Series

Computer-controlled Cycle Machine with Input Function

>See details

>AMS Series

LK-1910(60mm(L)×100mm(W))

LK-1920(60mm(L)×100mm(W) : With intermediate presser)

Computer-controlled, High-speed Shape-tacking Machine

>See details

Pattern seamers

PS‐910 Series

(Machine Head Rotation)

Machine Head Rotation Pattern Seamer

PS-910-13090

>See details

PS-910-6055

>See details

800 Series

(large size)

Pattern Seamer

PS-800 Series

>See details

800 Series

(For small production lines)

Small size Pattern Seamer

PS-800-8045

>See details

PS-800-3830

>See details

PS-800SB-2850

>See details

JTRON Series

The sewing automation solutions that JTRON products provide help manufacturers improve their production capacities and the quality of their workshop standards for enhanced competitiveness. The high operability and quality of JTRON satisfy professionals who seek to achieve the best possible quality and production capacity from any type of facility or automatic machine they are using. JUKI constantly pursues not only higher functions and performance, but also improved production capacity in processes. The "J" in JTRON stands for "JUKI" and "JAPAN." The "TRON" that comes after the “J” is the Greek suffix for "tool" or "instrument." The automatic machines and equipment from JTRON embody the spirit of JUKI and Japan. The adoption of JUKI’s certified sewing machines pushes reliability levels higher. JUKI draws from its limitless knowledge of sewing processes to promise uniquely ideal operability.