Are you planning to build a new factory, extend an existing factory and lines, or switching production items?

JUKI provides a service to help customers build optimized lines by estimating production facilities, target production quantity, and the required number of operators.

Take advantage of JUKI's plant design service to build your optimized lines.

Plant Design

- Home

- Services

- Plant Design

Plant Design

Case Studies

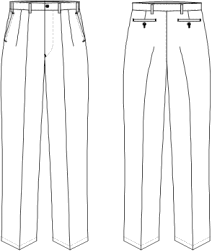

I want a line capable to manufacture 2,000 pairs of trousers.

Can you provide an estimate?

Can you provide an estimate based on our actual production item samples?

Case Study 1: Estimate according to the target items and production status

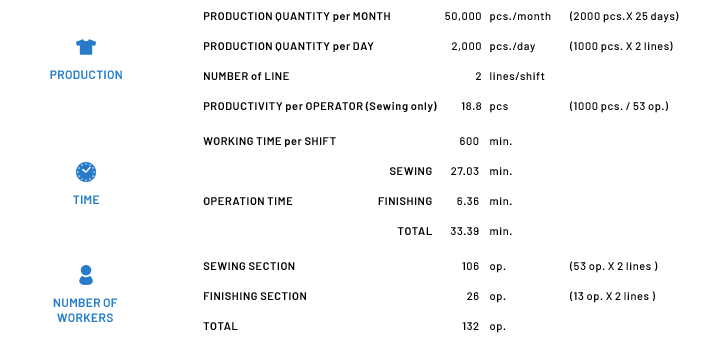

Estimates below are available according to the customer's target items and production status:

- Estimate details

- 1. Basic Data: Target production quantity per day, factory operation time, number of operators

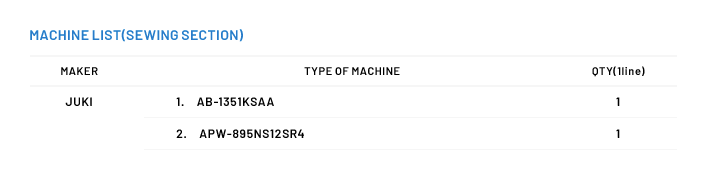

2. Facility List: Model names, number of sewing machines

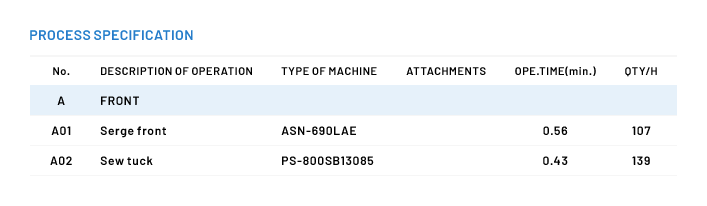

3. Process Analysis Sheet: Process names, process time, production quantity per day of each line

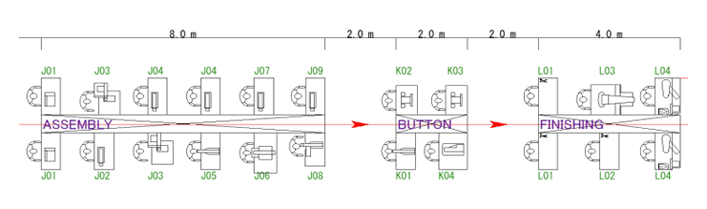

4. Floor Layout: Machine layout, product flow, sizes of lines/factory

Case Study 2: Estimate based on the actual production item samples

Please send your production item samples and request an estimate based on the production processes of the items. The estimate is provided in the same manner as described above.

For a jacket, for example, the estimate elements includes the label shape, the number of sleeve buttons, vent type, facing shape, presence/absence of lining.

By designing the line for the most difficult item among your production items, JUKI can offer a proposal capable of manufacturing other easier items.