Computer-controlled, Eyelet Buttonholing Sewing System

(Trimmer for Needle and Looper Thread with gimp)

The digitally controlled machine permits the selection and setting of various eyelet shapes.

We thoroughly pursue operability and realized easy operation with a new operation panel.

Product features

Color LCD touch panel for intuitive operation

Configured with a large, highly visible color LCD touch panel for instant display of the stitch shape, set values, and menu settings for the sewing functions. Fast, intuitive touch-panel operation reduces the time taken to set the data and eliminates mistakes in sewing and machine operation.

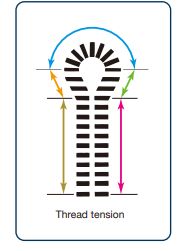

An active tension mechanism (computer-controlled thread tension mechanism)

Electronic control of the needle/looper thread tensionNeedle and looper thread tensions can be digitally established on the operation panel according to sewing conditions. The machine also ensures the consistent production of high-quality seams.

• Data registration on a pattern-by-pattern basis

• Easy reproduction of the same sewing conditions

Using conventional machines, it's often quite difficult to reproduce the same sewing conditions. This machine does it with ease. With this capability, the MEB-3200C responds immediately to material changes, significantly reducing the time required for setup changes or adjustments. The machine also ensures the consistent production of high-quality seams. With the further improvements achieved, the pressure fluctuations are reduced during sewing to increase the stability of the thread tension. And with the very small differences in thread tension between sewing machines, the same thread tension can be obtained using the same sewing data.Thread tensions can be separately established for various sections of a buttonhole such as eyelet sections and parallel sections

● The machine promises high-quality seams by smoothly responding to changes in stitch formation and allowing the operator to set a separate thread tension for the bartacking sections of buttonholes.

● Thread tensions for the beginning and end of sewing can also be separately established. This helps prevent loose stitches or slip-off or raveling of thread at the beginning of sewing.Easier threading

Threading work, a cumbersome process with conventional eyelet buttonholing machines, is now made easier with an air gun to blow the thread.

Management of sewing performance and sewing machine by the utilization of IoT (Internet of Things)

Management, browsing and editing of data can be carried outon the application software

Data on sewing machine adjustments made according to the product to be sewn can be transferred to a commercially-available Android tablet in contactless mode. This enables quick check for uniform settings as well as confirmation of conditions of sewing machines in a sewing line, thereby facilitating setup changes. The operation panel is also provided as standard with a USB port. Data management and software update can be carried out with ease using a USB thumb drive.Automatized knife pressure

The pressure of the cloth-cutting knife is now controlled automatically. Once the pressure is set, it holds steady even when the knife guard height or other conditions are changed. The steady control achieved eliminates the need for knife pressure readjustment when the knife guard is changed or repaired. The setup changing time is substantially reduced. (A different knife pressure can be set for every sewing pattern.) The automatized knife pressure control, together with the active tension of the needle and looper threads, significantly reduces manhours when skilled workers are in short supply.

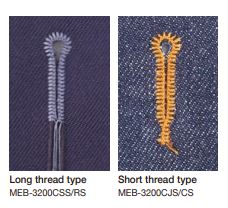

Consistent overall thread-trimming mechanism

When the MEB-3200CSS/RS for men's and ladies' wear trims the needle thread, looper thread, and gimp, it leaves a long strip of thread/gimp remaining on the material. With a sufficient length of thread/gimp to hold by hand, the operator can easily carry out the bartacking in the next process. When the MEB-3200CJS for jeans and MEB-3200CCS for cotton pants / work pants trim the needle thread, looper thread, and gimp, they leave only a short thread/gimp on the material. With no thread nipping required, work efficiency and productivity are both improved.

Basic performance

Vertically driven cloth cutting knife controlled by a stepping motor

● Thanks to the stepping motor control, the knife pressure can be easily changed on the operation panel to suit the material, thereby preventing uneven cutting.

● Changeover between the cut-before knife and cut-after knife can be carried out on the operation panel.

● With the air gun configured in place of an air-driven knife, parts such as the knife-driving arm no longer break and fluctuations in the air pressure driving the knife no longer cause uneven cutting. The air gun consumes only one-seventh of the air consumed by a standard eyelet buttonholing machine, which eliminates the need for a high-capacity compressor.Separately driven right and left work clamps

The right and left work clamps are separately driven by independent air cylinders. With this mechanism, the work clamps reliably clamp materials of different thicknesses to prevent the materials from flopping.

Reduced power consumption in standby

In addition to reducing power consumption in standby mode (55% compared to a conventional buttonholing sewing system), the new motor control also reduces heat generation in the machine head. With its improved features, such as its wind-resistant thread path and cloth-cutting mechanism shielded from air pressure fluctuations, this machine provides consistent seam quality in any operating environment.

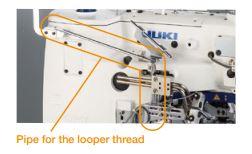

Equipped with a shield to protect the looper thread path from wind

The pipe-type thread path that comes with the machine reduces thread friction and protects the thread against the effects of wind. This thread path can be easily threaded with an accessory air gun.

Newly developed machine head that efficiently sews longitudinal buttonholes

● JUKI has newly developed a machine head with a shallow recess. For the efficient sewing of longitudinal buttonholing.

⁕Use MEB-3200CRS for combined use for lateral and longitudinal buttonholing.

● The machine head has a wider space under the work clamps to permit easy placement of a sewing product, thereby improving workability.

● The semi-sunken machine head promises easy placement and smooth handling of sewing products.

● The amount of material opened can be easily adjusted using the screw mounted outside the machine head.Direct-drive motor is adopted

The machine has adopted a direct-drive method that connects a compact AC servomotor directly to the hook-driving shaft. The quick startup and increased stopping accuracy obtained as a results guarantees outstanding responsiveness. In addition, the direct-drive motor does not use a V-belt to reduce power consumption.

Excellent maintainability

● The computer controlled design eliminates most of the complicated mechanisms. This dramatically improves maintainability.

● The machine head is supported by a gas-spring that makes it easy to raise for smoother cleaning and threading.Improvements of working environment

● Designed without a clutch mechanism or stopmotion mechanism, the machine produces no stop-motion noise.

● The machine automatically reclaims cloth chips after cloth cutting action to keep the working environment cleaner.Equipped with a color-tunable LED light

The machine is equipped with a color-tunable LED light that can be adjusted from daylight white to light bulb color. The LED can be adjusted to suit the sewing material and environment for improved workability.

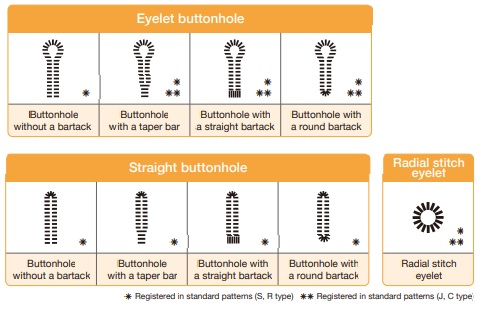

Thanks to the computer control, many different eyelet shapes and straight buttonhole shapes can be selected or established on the operation panel

The machine is provided as standard with 11 different stitching shape patterns. As many as 88 different patterns can be stored in memory and selected.

Specification

| Model name | MEB-3200CSS | MEB-3200CRS | MEB-3200CJS | MEB-3200CCS |

|---|---|---|---|---|

| Application | Men's and ladies' wear | Combined use for lateral and longitudinal buttonholing: for men's and ladies' wear | Jeans | Cotton pants and working wear |

| Thread trimming style | Longer remaining thread | Shorter remaining thread | ||

| Stitch system | 1-needle, double chainstitch (with gimp) | |||

| Max. sewing speed | 400~2,200sti/min*1 (100sti/min*1 step) | |||

| Sewing length | 10~38mm (with thread trimmer) 10~50mm (in case looper thread trimming device is removed)*2 |

Work clamp type S 16~24 (26)mm: optional Work clamp type M 24~32 (34)mm: standard Work clamp type L 32~40 (42)mm: optional |

Work clamp type S 16~24 (26)mm: standard Work clamp type M 24~32 (34)mm: optional Work clamp type L 32~40 (42)mm: optional |

|

| The figures in ( ) parentheses are in case of taper bar | ||||

| Needle throwing width (at the time of delivery) |

2.0~3.2mm*2 | 2.6~4.0mm*3 | 2.0~3.2mm*3 | |

| (2.3mm) |

(3.6mm) |

(2.5mm) | ||

| Taper bar length | 0mm, 3~15mm | |||

| Work clamp height | 13mm (max. 16mm) | |||

| Method for changing stitch shape | By selecting a program | |||

| Buttonhole cutting method | By cut-before knife or cut-after or without buttonhole cutting | |||

| Feed system | Intermittent feed by stepping motor | |||

| Cloth cutting knife drive system | Vertically driven by stepping motor | |||

| Needle (at the time of delivery) |

DO×558 (Nm100) Nm90~Nm110 |

DO×558 (Nm120) Nm120~Nm130 |

DO×558 (Nm110) Nm110~Nm120 |

|

| Lubrication | Automatic (looper and spreader: by an oiler) | |||

| Lubricating oil | JUKI New Defrix Oil No.2 (equivalent to ISO VG32) | |||

| Compressed air and air consumption | 0.5MPa 6dm³/min (ANR) [8cycle/min] | |||

| Power requirement and power consumption | Single-/3-phase, 550VA | |||

| Dimensions | 1,060mm (W)×790mm (D)×1,230mm (H) | |||

| Total weight | 179kg | |||

*1 "sti/min" stands for "Stitches per Minute."

*2 When the sewing length of 38~50mm without thread trimmer is selected, the work clamp can be provided by placing special order.Please use the Multi-cutting device when you cut the cloth.

*3 By selecting the left looper and left spreader, the range of stitch bite can be changed to 2.6~4.0mm from 2.0~3.2mm (TS model is excluded)

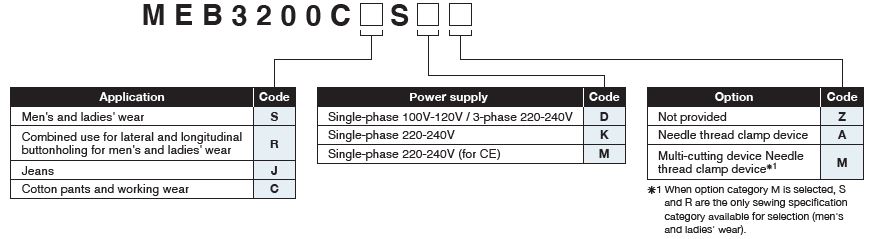

When you place orders