Semi-dry head, 2-needle Lockstitch Sewing System

Inspire the Knowledge in Sewing Adjustment.

Epoch-making Sewing Systems in history.

Digital sewing system proposes the production process added with a computerized new value to all the people who engage in production.

Product overview

Product features

Active tension mechanism is adopted

Seam quality is improved by introducing the separately-driven right and left active tension mechanisms.

- The needle thread tension is automatically corrected according the sewing speed. Consistently seam quality is, therefore, achieved regardless of changes in sewing speed.

- The needle thread tension is automatically corrected according to the remaining amount of bobbin thread. Seam quality is, therefore, stabilized even when the remaining amount of bobbin thread has reduced.

- In the case of using the automatic needle thread tension correction feature according to the remaining amount of bobbin thread, the bobbin-thread change notification signal is provided to warn the operator when the remaining amount of bobbin thread has reduced to the predetermined level.

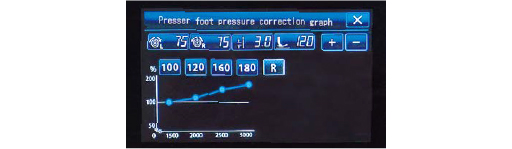

Active presser foot mechanism is adopted

Thanks to the adoption of the active presser foot, the presser foot pressure can now be corrected according to the sewing speed.

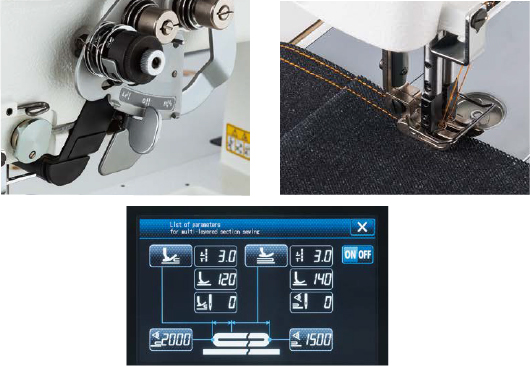

Multilayered portion detection device (S/G type: Standard equipment, F type: Option)

The sewing machine is provided as standard with the multilayered portion detection device.

This device contributes to the realization of stable pitch / well-tensed seam when sewing the multilayered portion.

Since the sewing correction can be respectively set the multilayered portion run-on portion and for the top of multilayered portion, stitch gathering at the multilayered portion can be improved.

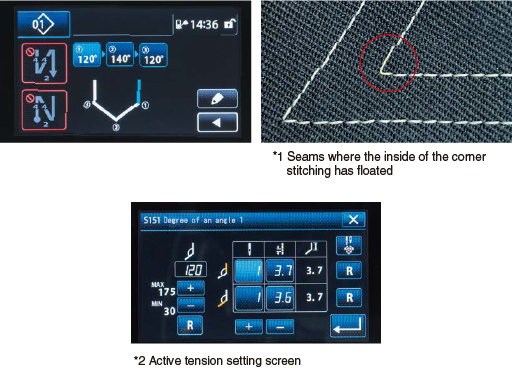

Corner stitching capability has been improved (only for the LH-4588C)

Changeover from the normal stitching to the corner stitching is carried out semi-automatically using the lever while ensuring ease of operation. The operator only needs to input data on the needle gauge/stitching angle through the operation panel. Then, the operator can start the corner stitching only by operating the lever during sewing. Thereafter, the sewing machine automatically changes the sewing mode between the normal stitching and the corner stitching. This means that even the inexperienced operator can produce consistent seam quality while improving productivity. In addition, the problem that the seam inside the corner stitching floats*1 can be solved by the active - tension correction function².

Reduction of setup changing time

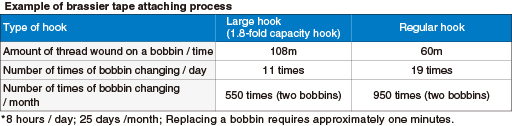

- A large hook of 1.8-fold capacity (as compared with the standard size hook) is adopted.

As a result, frequency of thread changing is reduced in half. This is the world’s first sewing machine not only for jeans and heavy-weight materials, but also for foundation and medium-weight materials that is provided with a large hook. This sewing machine provides further stable seam quality. - Motor-controlled horizontal feed is introduced. Stitch pitch can be set on the operation panel.

- A large hook of 1.8-fold capacity (as compared with the standard size hook) is adopted.

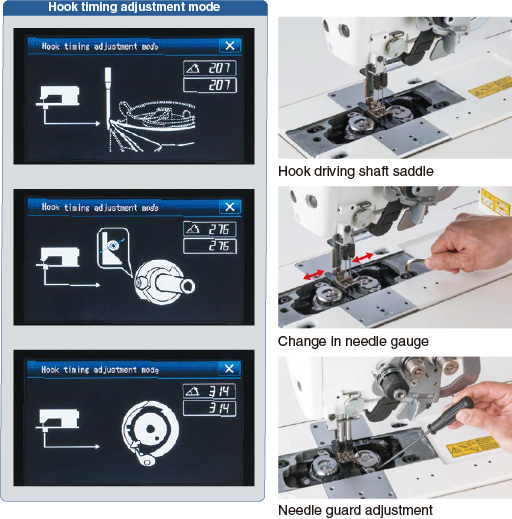

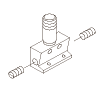

Reduction in time required for adjustment of hook timing

Hook timing adjustment is required in the case of changing the needle gauge. The time required for this adjustment is reduced. Adoption of the hook timing adjustment mode that can be activated by operating the operation panel as well as new hook driving shaft saddle achieves substantial reduction in workload required at the time of changing the needle gauge. Needle guard of the hook can be adjusted with screw with ease.

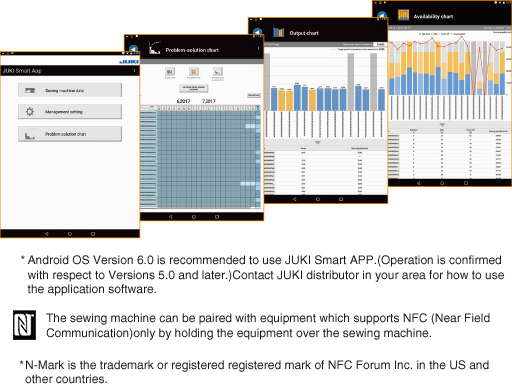

Data and sewing machine management with IoT ( Internet of Things)

A "Two-way" contactless communication for parameter adjustment data can be conducted with the sewing machine by a commercial Android terminal.

This feature allows sewing machines in a sewing line to be uniformly set and status checked quickly, thereby contributing to stabilization in product quality.

Control panel is standardized with USB ports, promising simplicity in data management and system updates.

JUKI Smart APP allows you to send and confirm various data

In the application, there are items of management setting (terminal registration), sewing machine data (sewing data), problem-solution chart.

In the problem-solution chart, we can generate production graphs, the availability chart, etc. for each acquired sewing machine data so it can be used for checking the current situation and analyzing it.

Large hook (1.8-fold capacity hook) is adopted for foundation type and medium-weight type

A larger hook (1.8-fold capacity hook) is adopted for foundation type that use thin threads and for medium-weight type. This is the world’s first use of a large hook (1.8-fold capacity hook) for foundation type and medium-weight material type. As a result, the frequency of thread changing is reduced by approximately 40%, the work hours are reduced and the operator’s fatigue is reduced. In addition, the bobbin thread remaining amount correction function of this machine contributes to more consistent seam quality.

Basic performance

Operator fatigue reduction

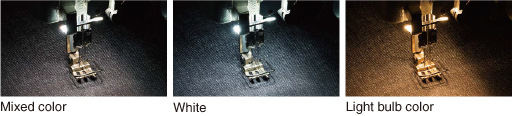

For the LED hand light, the improved toning function with two additional colors (white / light bulb color) is provided.

This LED hand light helps reduce the operator's eye fatigue who is engaged in sewing work for a long time.

Automatic OFF function of the operation-panel backlight

The operation-panel light can be turned OFF after a lapse of the preset time. can be automatically turned OFF. (The setting is from 1 to 20 minutes.)

Sleep mode (Automatic power-OFF function)

If no operation is carried out for a predetermined period of time, power supply such as motor can be turned off. (The setting is from 1 to 50 minutes.)

*These options can be set up on the operation panel.

Reduction in power consumption

Since the LH-4500C is provided with a compact AC servomotor, optimized presser foot lifting control method and the actuator with increased power efficiency, its power consumption is reduced by 30.8 % as compared with the LH-3500A. In addition, the power consumption during standby state is reduced by 50.8 % due to the operation panel screen on which display can be turned OFF.

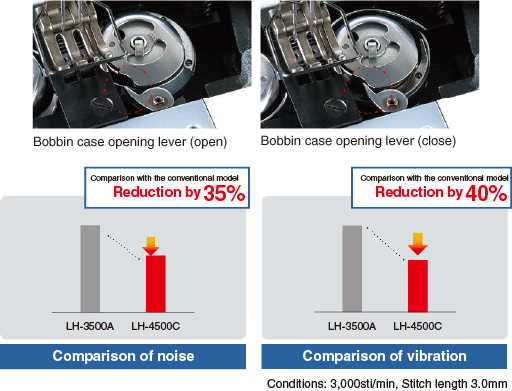

Reduction in noise / vibration

Noise / vibration produced by the LH-4500C is reduced by various improvements such as the adoption of 1/2 opener system. The LH-4500C provides the work environment that helps reduce the operator's fatigue.

Specification

| Model name | LH-4578CFF | LH-4578CFS | LH-4578CFS-7 | LH-4588CFS-7 | LH-4578CFG-7 | LH-4588CFG-7 |

|---|---|---|---|---|---|---|

| Specification | Full digital | |||||

| Application | Foundation | Medium-weight | Jeans and heavy-weight materials | |||

| Corner stitching (Organized split needle bar mechanism) |

Not provided | provided | Not provided | provided | ||

| Lubricating system | Semi-dry / Hook section: Minute-quantity lubrication (tank system) | |||||

| Feed system | Needle feed | |||||

| Max. sewing speed | 3,000 sti/min* | |||||

| Max. stitch length | 4mm | 5mm | 7mm | |||

| Thread take-up lever | Slide type | |||||

| Needle bar stroke | 33.4mm | |||||

| Needle thread tension | Independent right and left active tension mechanism | |||||

| Active presser foot | Standard | |||||

| Lift of the presser foot (max.) | 13mm | |||||

| Multilayered portion detection | Option | Standard | ||||

| Knee lifter | Option | |||||

| Reverse feed stitching lever | Not provided | Standard | ||||

| Needle | DP × 5 #10 (#9~#16) |

DP × 5 #14 (#9~#16) |

DP × 5 #21 (#16~#23) |

|||

| Thread used | #80 - #30 |

#30 - #3 (for #8 - #3, bobbin thread count should be #20) |

||||

| Hook | Vertical-axis large hook (1.8 - fold ) | |||||

| Free space under the arm | 120 mm (height) x 266 mm (distance from machine arm to needle) x 87 mm (height of the jaw section) | |||||

| Lubricating oil | JUKI New Defri x Oil No.1 (Equivalent to ISO VG7) | |||||

* sti/min is the abbreviation for "stitches per minute"

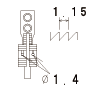

When you place orders

Gauge

LH-4578CFF

| Guage | FEED DOG | FEED DOG | NEEDLE CLAMP ASM. | PRESSER FOOT ASM. | SWIVEL GUIDE PRESSER ASM. | THROAT PLATE FOR BINDING | THROAT PLATE | SLIDE PLATE ASM. | ||

|---|---|---|---|---|---|---|---|---|---|---|

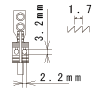

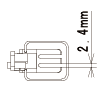

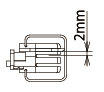

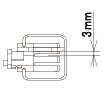

| Figure |  |

|

|

|

|

|

|

|

||

| Needle width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | ||

| Code | inch | mm | ||||||||

| B | 1/8 | 3.2 | 40232781 | 40232780 | 10147650 | 22627152 | 22647051 | 40232772 | 22625107 | 40220206 |

| C | 5/32 | 4.0 | - | - | 10147759 | - | - | 40232773 | 22625206 | 40220206 |

| D | 3/16 | 4.8 | 40033564 | 40035884 | 10147858 | 22627350 | 22647150 | 40232774 | 22625305 | 40220206 |

| E | 7/32 | 5.6 | 40033565 | 40035885 | 10147957 | 22627459 | 22647259 | 40232775 | 22625404 | 40220206 |

| F | 1/4 | 6.4 | 40033566 | 40035886 | 10148054 | 22627558 | 22647358 | 40221496 | 22625503 | 40220206 |

| G | 9/32 | 7.1 | 40033567 | 40035887 | 10148153 | 22627657 | 22647457 | 40232776 | 22625602 | 40220206 |

| H | 5/16 | 7.9 | 40033568 | 40035888 | 10148252 | 22627756 | 22647556 | 40232777 | 22625701 | 40220206 |

| K | 3/8 | 9.5 | - | - | 10148351 | - | - | - | 22625800 | 40220206 |

| W | 7/16 | 11.1 | - | - | 10148450 | - | - | - | 22625909 | 40220206 |

| L | 1/2 | 12.7 | - | - | 10148559 | - | - | - | 22626006 | 40222670 |

| M | 5/8 | 15.9 | - | - | 10148658 | - | - | - | 22626105 | 40222670 |

| N | 3/4 | 19.1 | - | - | 10148757 | - | - | - | 22626204 | 40222670 |

| P | 7/8 | 22.2 | - | - | 10148856 | - | - | - | 22626303 | 40222671 |

| Q | 1 | 25.4 | - | - | 10148955 | - | - | - | 22626402 | 40222671 |

| R | 1-1/8 | 28.6 | - | - | 10149052 | - | - | - | 22626501 | 40222671 |

| S | 1-1/4 | 31.8 | - | - | 10149151 | - | - | - | 22626600 | 40222672 |

| T | 1-3/8 | 34.9 | - | - | 10149250 | - | - | - | 22626709 | 40222672 |

| U | 1-1/2 | 38.1 | - | - | 10149359 | - | - | - | 22626808 | 40222672 |

| Remarks | - | Option | Hole Type | - | For foundation | For foundation | ||||

| Guage | SLIDE PLATE ASM._FRONT | SLIDE PLATE ASM._FRONT | ||

|---|---|---|---|---|

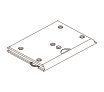

| Figure |  |

|

||

| Needle width | P/N | P/N | ||

| Code | inch | mm | ||

| B | 1/8 | 3.2 | 40042874 | 23206709 |

| C | 5/32 | 4.0 | 40042874 | 23206709 |

| D | 3/16 | 4.8 | 40042874 | 23206709 |

| E | 7/32 | 5.6 | 40042874 | 23206709 |

| F | 1/4 | 6.4 | 40042874 | 23206709 |

| G | 9/32 | 7.1 | 40042874 | 23206709 |

| H | 5/16 | 7.9 | 40042874 | 23206709 |

| K | 3/8 | 9.5 | 40042874 | 23206709 |

| W | 7/16 | 11.1 | 40042874 | 23206709 |

| L | 1/2 | 12.7 | 40042874 | 23206709 |

| M | 5/8 | 15.9 | 40042874 | 23206709 |

| N | 3/4 | 19.1 | 40042874 | 23206709 |

| P | 7/8 | 22.2 | 40042874 | 23206709 |

| Q | 1 | 25.4 | 40042874 | 23206709 |

| R | 1-1/8 | 28.6 | 40042874 | 23206709 |

| S | 1-1/4 | 31.8 | 40042874 | 23206709 |

| T | 1-3/8 | 34.9 | 40042874 | 23206709 |

| U | 1-1/2 | 38.1 | 40042874 | 23206709 |

| Remarks | ||||

LH-4578CFG-7

| Guage | THROAT PLATE | NEEDLE CLAMP ASM. | FEED DOG | FEED DOG | PRESSER FOOT ASM._TIP DIVIDED | SWIVEL GUIDE PRESSER ASM. | SWIVEL GUIDE PRESSER ASM. | SLIDE PLATE ASM. | ||

|---|---|---|---|---|---|---|---|---|---|---|

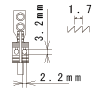

| Figure |  |

|

|

|

|

|

|

|

||

| Needle width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | ||

| Code | inch | mm | ||||||||

| B | 1/8 | 3.2 | 40232755 | 10147650 | - | 40232778 | - | 40229469 | - | 40220206 |

| C | 5/32 | 4.0 | 40232756 | 10147759 | 40232779 | - | 40071909 | - | - | 40220206 |

| D | 3/16 | 4.8 | 40232757 | 10147858 | 40035891 | 40025831 | 22816557 | 40229461 | 40095293 | 40220206 |

| E | 7/32 | 5.6 | 40232758 | 10147957 | 40050009 | 40025832 | 22816656 | - | - | 40220206 |

| F | 1/4 | 6.4 | 40220201 | 10148054 | 40035892 | 40025833 | 22816755 | 40229459 | 40094776 | 40220206 |

| 40220209 * | 40220207 * | |||||||||

| G | 9/32 | 7.1 | 40232759 | 10148153 | 40050010 | 40025834 | 22816854 | - | - | 40220206 |

| H | 5/16 | 7.9 | 40232760 | 10148252 | 40050011 | 40025835 | 22816953 | - | - | 40220206 |

| K | 3/8 | 9.5 | 40232761 | 10148351 | 40035893 | 40025836 | 22817050 | - | - | 40220206 |

| W | 7/16 | 11.1 | 40232762 | 10148450 | - | 40025837 | 40033941 | - | - | 40220206 |

| L | 1/2 | 12.7 | 40232763 | 10148559 | 40035894 | 40025838 | 22817159 | - | - | 40222670 |

| M | 5/8 | 15.9 | 40232764 | 10148658 | 40071912 | 40025839 | 40033945 | - | - | 40222670 |

| N | 3/4 | 19.1 | 40232765 | 10148757 | 40035895 | 40025840 | 40033947 | - | - | 40222670 |

| P | 7/8 | 22.2 | 40232766 | 10148856 | 40071913 | 40025841 | 40033949 | - | - | 40222671 |

| Q | 1 | 25.4 | 40232767 | 10148955 | 40071914 | 40025842 | 40033951 | - | - | 40222671 |

| R | 1-1/8 | 28.6 | 40232768 | 10149052 | 40071915 | 40025843 | 40033953 | - | - | 40222671 |

| S | 1-1/4 | 31.8 | 40232769 | 10149151 | 40071916 | 40025844 | 40033955 | - | - | 40222672 |

| T | 1-3/8 | 34.9 | - | 10149250 | - | - | - | - | - | - |

| U | 1-1/2 | 38.1 | - | 10149359 | - | - | - | - | - | - |

| Remarks | Hole Type | Option,*For 3 # thread | Option,* For 3 # thread | |||||||

| Guage | SLIDE PLATE ASM._FRONT SLIDE PLATE ASM._FRONT | ||

|---|---|---|---|

| Figure |  |

||

| Needle width | P/N | ||

| Code | inch | mm | |

| B | 1/8 | 3.2 | 40042880 |

| C | 5/32 | 4.0 | 40042880 |

| D | 3/16 | 4.8 | 40042880 |

| E | 7/32 | 5.6 | 40042880 |

| F | 1/4 | 6.4 | 40042880 |

| G | 9/32 | 7.1 | 40042880 |

| H | 5/16 | 7.9 | 40042880 |

| K | 3/8 | 9.5 | 40042880 |

| W | 7/16 | 11.1 | 40042880 |

| L | 1/2 | 12.7 | 40042880 |

| M | 5/8 | 15.9 | 40042880 |

| N | 3/4 | 19.1 | 40042880 |

| P | 7/8 | 22.2 | 40042880 |

| Q | 1 | 25.4 | 40042880 |

| R | 1-1/8 | 28.6 | 40042880 |

| S | 1-1/4 | 31.8 | 40042880 |

| T | 1-3/8 | 34.9 | - |

| U | 1-1/2 | 38.1 | - |

| Remarks | - | ||

LH-4588CFG-7

| Guage | FEED DOG | FEED DOG | THROAT PLATE | PRESSER FOOT ASM._TIP DIVIDED | SWIVEL GUIDE PRESSER ASM. | SWIVEL GUIDE PRESSER ASM. | NEEDLE CLAMP ASM._LEFT | NEEDLE CLAMP ASM._RIGHT | ||

|---|---|---|---|---|---|---|---|---|---|---|

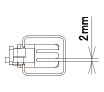

| Figure |  |

|

|

|

|

|

|

|

||

| Needle width | P/N | P/N | P/N | P/N | P/N | P/N | P/N | P/N | ||

| Code | inch | mm | ||||||||

| B | 1/8 | 3.2 | - | 40232778 | 40232755 | 40035896 | 40229469 | - | B1402528BA0A | B1402528BA0A |

| C | 5/32 | 4 | 40232779 | - | 40232756 | 40071909 | - | - | B1402528CA0A | B1402528CA0A |

| D | 3/16 | 4.8 | 40035891 | 40025831 | 40232757 | 22816557 | 40229461 | 40095293 | B1402528DALA | B1402528DARA |

| E | 7/32 | 5.6 | 40050009 | 40025832 | 40232758 | 22816656 | - | - | B1402528EAL | B1402528EAR |

| F | 1/4 | 6.4 | 40035892 | 40025833 * | 40220201 | 22816755 | 40229459 | 40094776 | B1402528FALA | B1402528FARA |

| 40220209 | 40220207 * | |||||||||

| G | 9/32 | 7.1 | 40050010 | 40025834 | 40232759 | 22816854 | - | - | B1402528GAL | B1402528GAR |

| H | 5/16 | 7.9 | 40050011 | 40025835 | 40232760 | 22816953 | - | - | B1402528HALA | B1402528HARA |

| K | 3/8 | 9.5 | 40035893 | 40025836 | 40232761 | 22817050 | - | - | B1402528KALA | B1402528KARA |

| L | 1/2 | 12.7 | 40035894 | 40025838 | 40232763 | 22817159 | - | - | B1402528LAL | B1402528LAR |

| M | 5/8 | 15.9 | 40071912 | 40025839 | 40232764 | 40033945 | - | - | B1402528MAL | B1402528MAR |

| N | 3/4 | 19.1 | 40035895 | 40025840 | 40232765 | 40033947 | - | - | B1402528NAL | B1402528NAR |

| P | 7/8 | 22.2 | 40071913 | 40025841 | 40232766 | 40033949 | - | - | B1402528PAL | B1402528PAR |

| Q | 1 | 25.4 | 40071914 | 40025842 | 40232767 | 40033951 | - | - | B1402528QAL | B1402528QAR |

| Remarks | - | Option,* For 3 # thread | - | - | *#3 For 3 # thread | - | DP5,Hole Type | DP5,Hole Type | ||

| Guage | NEEDLE CLAMP ASM._LEFT | NEEDLE CLAMP ASM._RIGHT | SLIDE PLATE ASM. | SLIDE PLATE ASM._FRONT | ||

|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

||

| Needle width | P/N | P/N | P/N | P/N | ||

| Code | inch | mm | ||||

| B | 1/8 | 3.2 | B1402526BA0A | B1402526BA0A | 40220206 | 40042880 |

| C | 5/32 | 4 | B1402526CA0A | B1402526CA0A | 40220206 | 40042880 |

| D | 3/16 | 4.8 | B1402526DALA | B1402526DARA | 40220206 | 40042880 |

| E | 7/32 | 5.6 | - | 10228567 | 40220206 | 40042880 |

| F | 1/4 | 6.4 | B1402526FALA | B1402526FARA | 40220206 | 40042880 |

| G | 9/32 | 7.1 | B1402526GALA | B1402526GARA | 40220206 | 40042880 |

| H | 5/16 | 7.9 | B1402526HALA | B1402526HARA | 40220206 | 40042880 |

| K | 3/8 | 9.5 | B1402526KALA | B1402526KARA | 40220206 | 40042880 |

| L | 1/2 | 12.7 | B1402526LALA | B1402526LARA | 40222670 | 40042880 |

| M | 5/8 | 15.9 | 10228856 | 10228864 | 40222670 | 40042880 |

| N | 3/4 | 19.1 | 10228955 | 10228963 | 40222670 | 40042880 |

| P | 7/8 | 22.2 | - | - | 40222671 | 40042880 |

| Q | 1 | 25.4 | 10229151 | 10229169 | 40222671 | 40042880 |

| Remarks | Option,For DP17 | Option,For DP17 | - | - | ||