Semi - Dry head, Digital Zigzag Stitch Sewing System

Inspire the Knowledge in Sewing Adjustment

Epoch-making Sewing Systems in history.

Digital sewing system proposes the production process added with a computerized new value to all the people who engage in production.

Product overview

Product features

Horizontal-/vertical-drive digital feed mechanism

The horizontal-/vertical-feed mechanism is controlled by motor.

The sewing machine can be adjusted with ease by operating the operation panel.The sewing machine provides the best-suited sewing performance according to the process and material

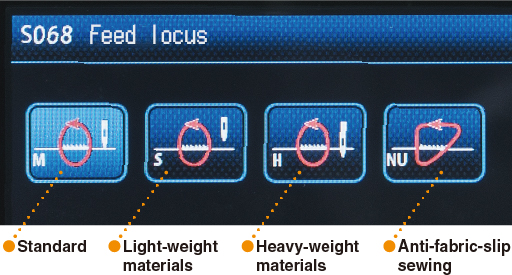

Change in feed timing has been a time-consuming operation. For the LZ-2290C, however, feed timing can be changed with ease by operating the operation panel. It is therefore possible to set the feed timing so as to produce the seam quality (soft⇔standard⇔hard) that is suited to the process.

In addition, the feed locus can be changed to that for preventing material slippage. With these improvement, the sewing machine provides further enhanced responsiveness to materials.

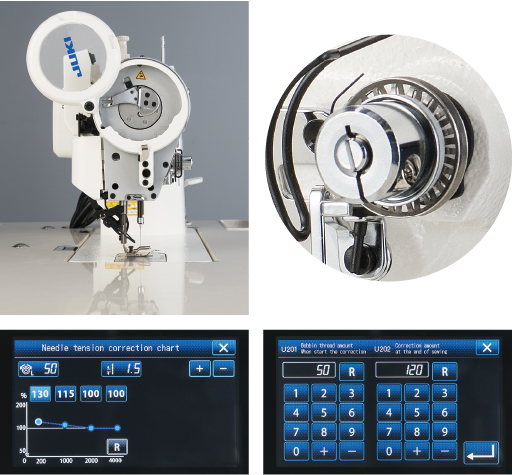

Rotary-type active tension has been adopted

The LZ-2290C is the world's first sewing machine that comes with the rotary-type active tension. Conventionally, it has been difficult to adjust the thread tension when the remaining amount of bobbin thread has reduced. This sewing machine, however, is able to correct and stabilize the thread tension by means of the active tension.

In addition, the thread tension can be corrected according to the sewing speed, thereby contributing to improved seam quality.

Active presser type can be selected

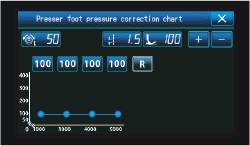

Thanks to the adoption of the active presser foot, the presser foot pressure can be corrected according to the sewing speed, and jumping during high-speed sewing can be suppressed.

(Select automatic foot lifter AK156 type at the time of factory shipment)

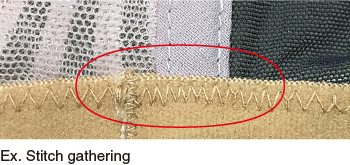

Multi-layered portion detection device is provided

The LZ-2290C is provided with the multi-layered portion detection device. Sewing conditions on a flat portion and that on a multi-layered portion of material can be respectively set.

As a result, conventional problems that are likely to occur when sewing a multi-layered portion of material such as stitch gathering and loose stitches can be prevented.

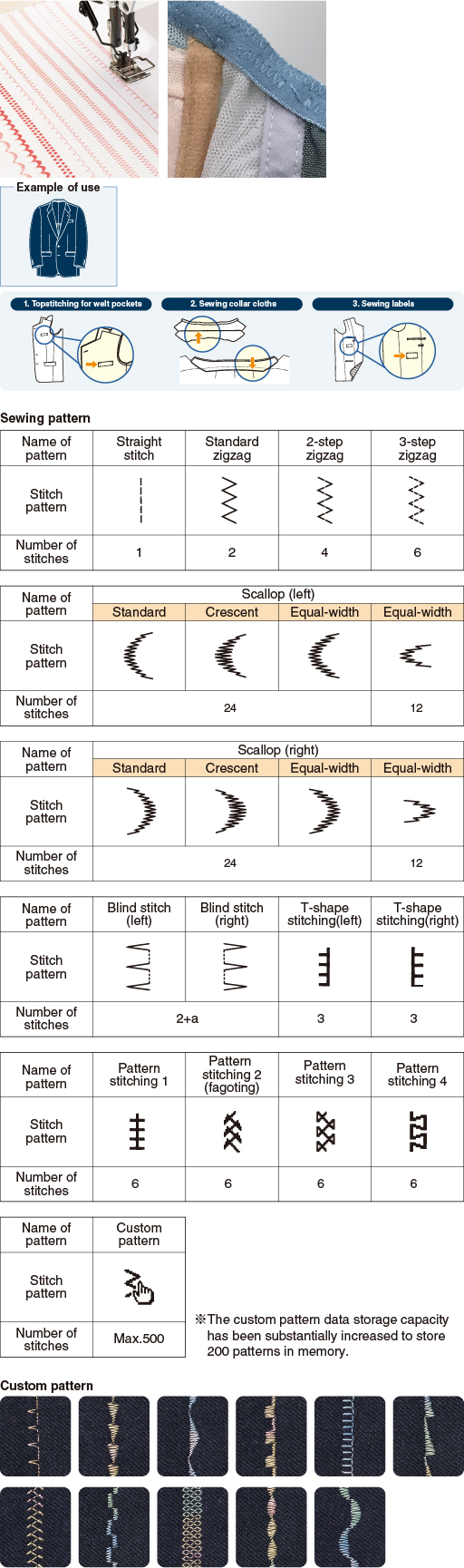

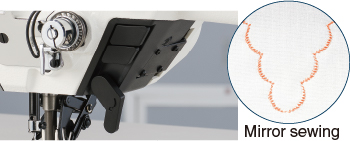

Sewing of diversified patterns is possible

The sewing machine is provided as standard with 11 types / 20 patterns of basic stitch shapes. Sewing patterns such as zigzag stitching, T stitching and pattern sewing can be selected on the new operation panel of the main body, thereby substantially increasing the facility operation rate.

In addition, a sewing pattern can be created for the brassiere sewing process for sewing a brassiere while skipping its bone portions. This also helps increase productivity.

For men’s garments, the machine is used in processes such as topstitching for welt pockets, sewing collar cloths and sewing labels. For ladies’ garments, it can perform pattern stitching for the collars and front bodies of jackets and blouses. In addition, original patterns can be created using the custom pattern feature, enabling the machine to be utilized for a broader range of uses.

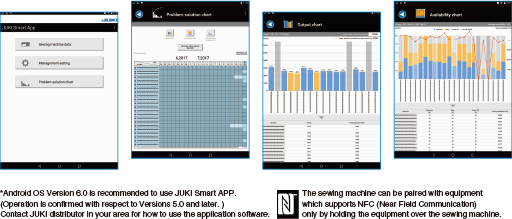

Data and sewing machine management with IoT (Internet of Things)

A "Two-way" contactless communication for parameter adjustment data can be conducted with the sewing machine by a commercial Android terminal. This feature allows sewing machines in a sewing line to be uniformly set and status checked quickly, thereby contributing to stabilization in product quality.

Control panel is standardized with USB ports, promising simplicity in data management and system updates.

JUKI Smart APP allows you to send and confirm various data

In the application, there are items of management setting (terminal registration), sewing machine data (sewing data), problem-solution chart. In the problem-solution chart, we can generate production graphs, the availability chart, etc. for each acquired sewing machine data so it can be used for checking the current situation and analyzing it.

Basic performance

Energy-saving function

Automatic OFF function of the operation-panel backlight

Back light of the panel is automatically turned off in the case the operation panel is not operated for a certain period of time. (The setting is from 1 to 20 minutes.)

Sleep mode (Automatic power-OFF function)

If no operation is carried out for a predetermined period of time, the power supplies to the motor, etc. (The setting is from 1 to 50 minutes.)

Structure with no oil pan

The semi-dry machine head that is supplied with grease has been developed. With this machine head, oil stains on sewn products are reduced.

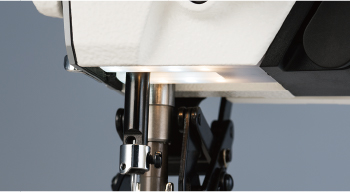

LED light

The LED light is provided as standard on the undersurface of arm jaw. In addition to the conventional function of the LED light, the color shade can be changed over as "white⇔neutral color (initial value)⇔incandescent" so as to help reduce the operator's eye fatigue.

Cooling fan

The cooling fan is laid out at the position that is best to reduce the heat generated by the hook unit.

Triple hand switch

The triple type hand switch has been introduced. The switch supports many different functions such as touch-back function, mirror function and multi-layered portion correction function.

Back lever

The back lever (reverse-feed lever) is provided as standard so as to support delicate sewing operations.

Hook timing adjustment mode

Hook timing can be safely adjusted while leaving the sewing machine ON by setting operation mode to the "Hook timing adjustment mode" on the operation panel.

Specification

| Model name |

Provided with automatic thread trimmer | LZ-2290CF-7 | ||

|---|---|---|---|---|

| Specification | Full digital type | |||

| Max. sewing speed*2 | 5,000 sti/min (4,000 sti/min at the time of shipment)*1 | |||

| Max. zigzag width | Standard 8 mm (up to 10 mm by changing the gauge) | |||

| Needle throwing mechanism | Motor control | |||

| Feed mechanism (horizontal direction) | Motor control | |||

| Feed mechanism (vertical direction) | Motor control | |||

| Max. feed amount | 5.0mm (2.5 mm at the time of shipment) | |||

| Thread take-up lever | Rotary thread take-up lever | |||

| Thread tension control mechanism | Rotary active tension | |||

| Multi-layered portion detection device | Provided | |||

| Presser system | Spring type (AK156 active presser type is digital type) | |||

| Amount of lift of presser foot | Hand lifter: 5.5mm / Knee-lifter: 10mm / Auto-lifter: 10mm | |||

| Auto-lifter | Selected on the machine head (motor control) | |||

| Hook | DP hook (titanium-coated inner hook) | |||

| Needle (at the time of shipment) | ORGAN DP × 5 (#10), SCHMETZ 438 (Nm 75) | |||

| Operation panel | Color touch panel (provided with the NFC function) | |||

| Number of standard sewing patterns | 11 types, 20 patterns | |||

| Memory capacity for custom patterns | 200 patterns | |||

| Max. number of stitches | 500 stitches/pattern | |||

| Continuous sewing pattern | Max. 20 patterns, 20 steps; 2,000 stitches/step | |||

| Main body input function | Provided (through the operation panel) | |||

| Hand switch | Triple switch (custom-setting is possible)) | |||

| LED | Provided as standard (provided with the dimmer / toning functions) | |||

| Bobbin winder | Built in the top part of machine head | |||

| Machine head drive | Compact AC servomotor: 400 W (direct-drive type) | |||

| Oiling | Semi dry (Frame: Lubricated with grease; Hook: Oil is supplied from the tank) | |||

| Lubricating oil | JUKI New Defrix Oil No. 1 (equivalent to ISO VG7) | |||

| Distance from machine arm to needle / Bed size | 300mm / 517mm × 178mm | |||

| Power consumption | 600VA | |||

| Product weight | 49.8kg | |||

*1 sti/min is the abbreviation for "stitches per minute".

*2 The maximum sewing speed varies depending on the stitch shape.

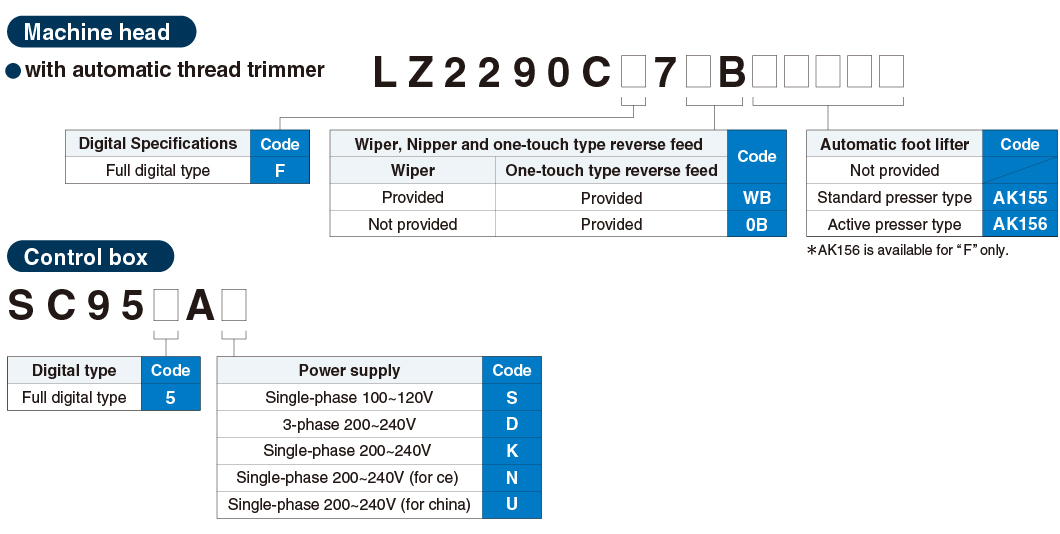

When you place orders