Pattern Seamer

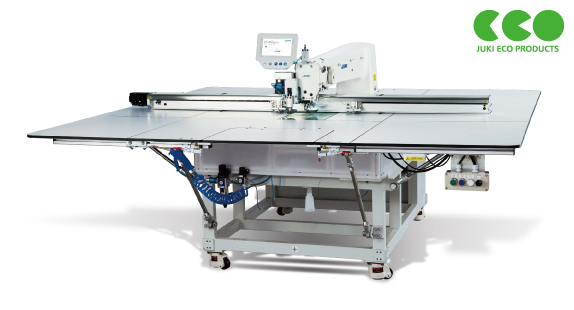

The dry head machine achieves max. speed 3,000sti/min with supporting various sewing and materials.

Your Ingenuity creates opportunities for Automation.

Product overview

Product features

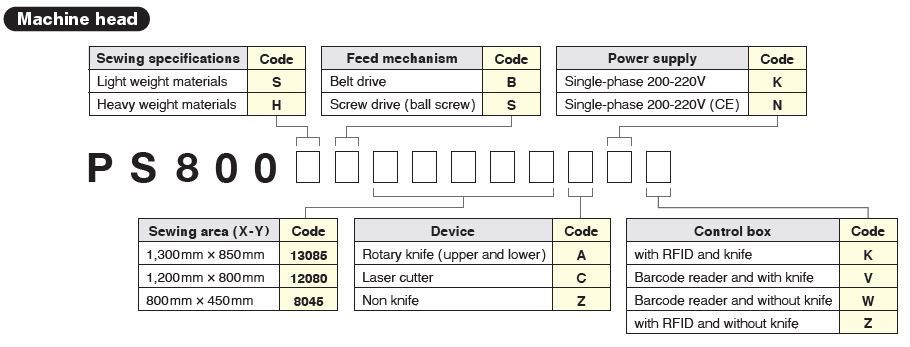

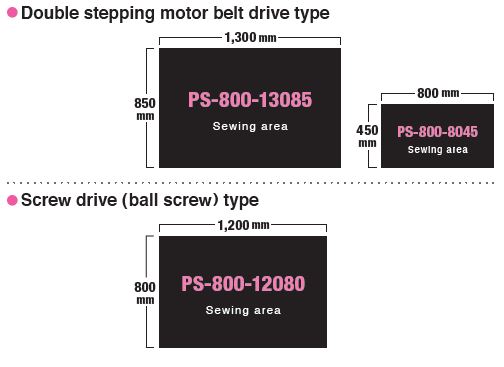

Feeding type and sewing area

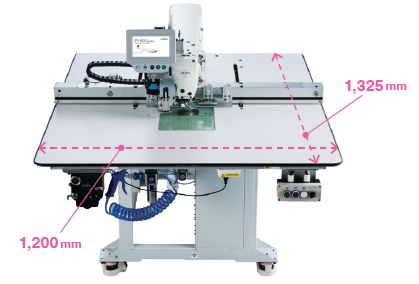

Space-saving PS-800-8045

The PS-800-8045 can be installed in a space-saving manner.Not only the parts department but also sewing lines can be used.(The table size of PS-800-8045 width is 1,200mm wideth, the same as 1-needle lockstitch machine.)

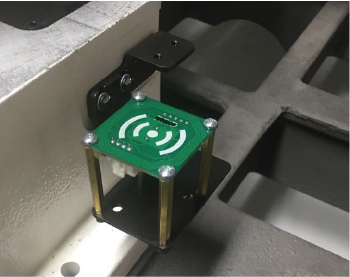

Patterns are identified by means of RFID/Barcode reader to enable automatic reading of sewing data

Sewing patterns are automatically identified by means of RFID/ Barcode reader to automatically call up the relevant sewing program, thereby starting sewing quickly.

*RFID (radio frequency identification): It is the technology to read and write data saved on IC chips through wireless non-contact transfer of radio frequency waves and is used to identify and manage products.

Operation panel

The sewing pattern data format are supports DXF, AI, PLT, and DST. Sewing pattern data in these formats are widely used in many sewing plants. As a result, the operation panel is able to use the customers’ existing sewing pattern data immediately. As many as 999 sewing patterns can be saved on the large-capacity memory of the operation panel. (Editing software is included with the accessory.)

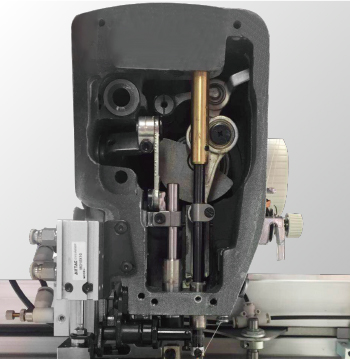

Oil stains are prevented

The machine head has adopted the advanced dry technology ( no lubrication is required ). Only the hook needs lubrication. The dry head is very effective when sewing materials on which oil stains are likely to spread such as those for down jackets.

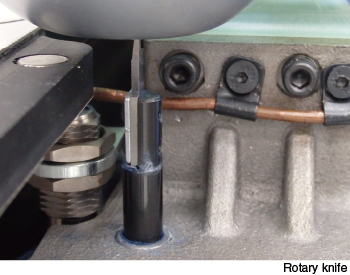

Cloth trimmer specifications

The cloth trimmer comes in two different knives and a laser.

- Rotary knife

This knife is suited to the sewing products designed to have straight portions and curve portions. - Laser cutter

This lazer is suited to soft materials such as knit.

- Rotary knife

Basic performance

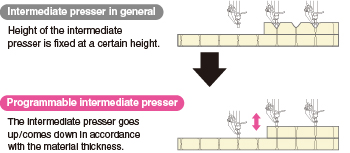

Height of the intermediate presser at its lower dead point can be adjusted on the operation panel

It is possible to change the intermediate presser height at its lower dead point steplessly during sewing. This feature is particularly effective when sewing multi-layered portions of material. Since the material is stably held by the intermediate presser, sewing troubles such as stitch skipping and thread breakage are prevented.

Specification

| Model name | PS-800SB13085 | PS-800HB13085 | PS-800SB8045 | PS-800HB8045 | PS-800SS12080 | PS-800HS12080 |

|---|---|---|---|---|---|---|

| Sewing area | 1,300 mm × 850 mm | 800 mm × 450 mm | 1,200 mm × 800 mm | |||

| Feeding type | Double stepping motor Belt Drive | Screw drive (ball screw) | ||||

| Max. sewing speed | 3,000 sti/min* | |||||

| Stitch length | 0.5 - 12.7 mm | |||||

| Hook | Full-rotary double-capacity hook | |||||

| Lift / Stroke of intermediate presser |

Lifting amount: 20 mm / Stroke: Standard 4 mm | |||||

| Variable lower position of the intermediate presser |

0 - 9 mm | |||||

| Needle | DB × 1 #8 (7#~14#) |

DP × 17 #21 (18#~23#) |

DB × 1 #8 (7#~14#) |

DP × 17 #21 (18#~23#) |

DB × 1 #8 (7#~14#) |

DP × 17 #21 (18#~23#) |

| Storage of pattern data in the memory |

Max. 999 patterns (80,000 sti/pattern) | |||||

| Number of Indentifiable patterns |

999 patterns | |||||

| Program input mode | USB | |||||

| File format | Convert DXF / AI / PLT / DST format to SLW format with editing softwear | |||||

| Weight | 500Kg | 450Kg | 750Kg | |||

| Dimensions | 2,190mm (W) × 2,100mm (L )× 1,250mm (H) | 1,200mm (W)× 1,325mm (L)× 1,250mm (H) | 2,180mm (W) × 2,185mm (L) × 1,250mm (H) | |||

*sti/min is the abbreviation for “stitches per minute”

When you place orders