Automatic Serging Machine

Super-high-speed serging machine developed to achieve a simple structure and ease of use

To fully support the operator so that he/she can carry out serging speedily, the machine comes in two different types; the long-table type and the short-table type which permits easy handling of the material.

Product features

Super-high-speed serging machine developed to achieve a simple structure and ease of use

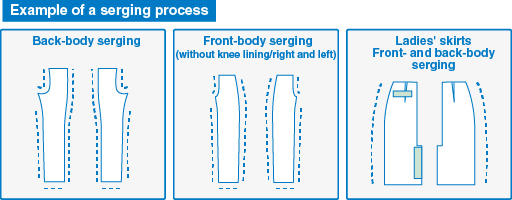

The machine is applicable to the over casting of material fabrics cut into various jeans, pants and skirt shapes.

The machine comes in two different types

To fully support the operator so that he/she can carry out serging speedily, the machine comes in two different types; the long-table type and the short-table type which permits easy handling of the material.

The table shape of the short-table type machine permits easy handling of the material to perform serging of a long material even when the work space is small.

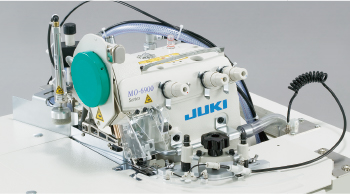

The machine is equipped with the super-high-speed overlock machine head MO-6904S

The machine achieves the high-speed performance of up to 8,000 sti/min to promise increased productivity. The machine performs serging according to the material used, is capable of sewing with reduced thread tension and promises consistent seam quality free from slip-off seams at curved parts of the material.

Flexible cloth guide

The cloth guide can easily be adjusted in height according to the material to be used without using a tool. It eliminates the troublesome changing of spacers.

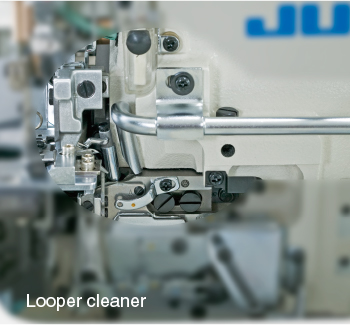

Looper cleaner

A dust extractor is equipped as standard in the upper looper arm section where dust is likely to gather. It helps prevent dust from accumulating inside the cloth chip cover.

Micro-lifter device

The machine is provided as standard with a micro-lifter device which adjusts the lifting amount of the presser foot to the material thickness to achieve improved seam quality, while preventing puckering and material damage.

Basic performance

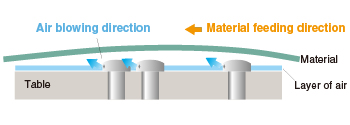

Air-blow table

The machine comes with an air-blow table, which issues a jet of air from its air nozzles at three locations to contribute to smoother handling of the material.

Easy-to-use stacker switch

The stacker automatically actuates according to the preset number of seams. In addition, the stacker can also be actuated by operating the large easy-to-press manual stacker switch.

Specification

| Model name | ASN-690 |

|---|---|

| Machine head | MO-6904S (Super-high-speed, 1-needle overlock machine) |

| Application | Serging of skirts, pants, jeans, etc. |

| Max. sewing speed | 8,000sti/min* |

| Stitch length | 0.8~4mm |

| Overedging width (mm) | 4.0, 4.8, 5.6 |

| Differential feed ratio | For gathering 1:2 (max. 1:4), For stretching 1:0.7 (max. 1:0.6) |

| Needle | DC×27 (#11) #9~#14 |

| Thread trimming device | Exclusive pneumatic side cutter |

| Lubrication | Automatic |

| Lubricating oil | JUKI MACHINE OIL 18 (equivalent to ISO VG18) |

| Compressed air | 0.5MPa |

| Power consumption | 590VA |

| Power requirement | Single-phase 200~240V, 3-phase 200~380V |

| Machine weight | Long-table type (L): 160kg (with stacker) |

| Short-table type (S): 110kg (with stacker) | |

| Dimensions | Long-table type (L) with stacker: 1,800mm (W) × 790mm (D) × 880mm (H) Long-table type (L) without stacker: 1,500mm (W) × 790mm (D) × 880mm (H) (When the Cloth table (KM-5) is used, the width is 2,100mm for the machine with a stacker, or 1,800mm for the one without a stacker.) Short-table type (S) with stacker: 790mm (W) × 875mm (D) × 880mm (H) Short-table type (S) without stacker: 790mm (W) × 575mm (D) × 880mm (H) |

* "sti/min" stands for "Stitches per Minute."

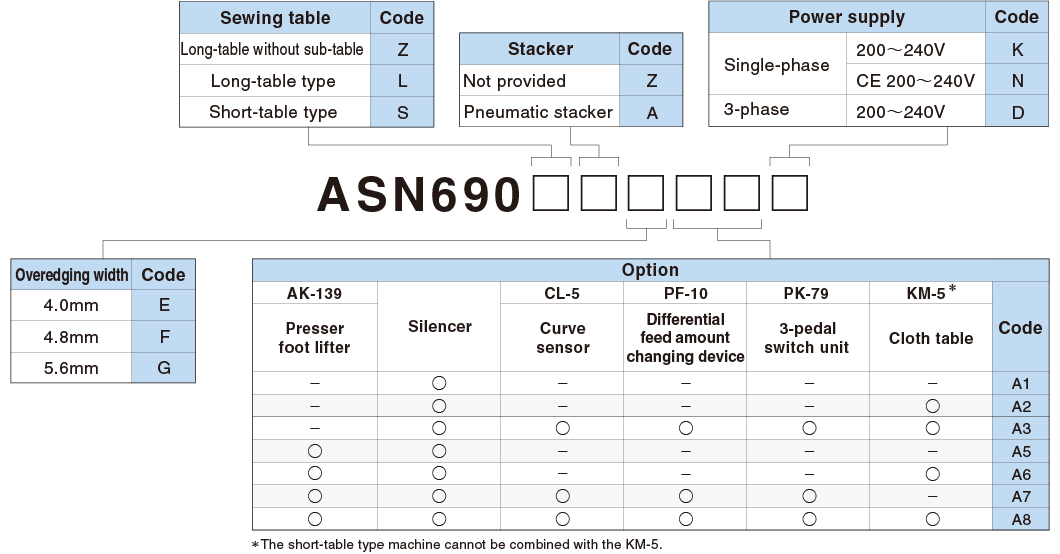

When you place orders

Gauge

ASN-690L

ASN-690S

| Guage | THROAT PLATE | |

|---|---|---|

| Figure |  |

|

| Overedging width(mm) | P/N | Remarks |

| 4.0 | 40082223 | E |

| 4.8 | 40082224 | F |

| 5.6 | 40082225 | G |

| Guage | MAIN FEED DOG | DIFFERENTIAL FEED DOG | AUXILIARY FEED DOG | PRESSER FOOT ARM | PRESSER FOOT ASSY |

|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

| P/N | G5811370000 | 40082207 | G5813370000 | G5909397000A | 40082217 |

| Guage | NEEDLE THREAD PRESSER GUIDE B | NEEDLE THREAD PRESSER PLATE C | NEEDLE THREAD PRESSER SPRING B | DIFFERENTIAL FEED CAM | NEEDLE PLATE BASE A |

|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

| P/N | 13110804 | 12112504 | 12112702 | 12112603 | 40082221 |