Computer-controlled, High-speed Shape-tacking Machine

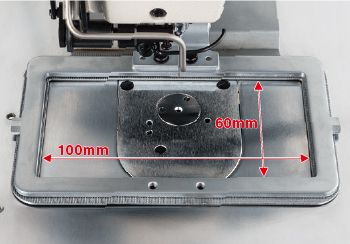

[Sewing area: 60mm(L)×100mm(W) ]

Pursuing both the high productivity and excellent operability.

Product features

Higher productivity

The sewing speed of 2,500 sti/min is the fastest-level sewing speed among the shape-tacking machines. The sewing machine has adopted a semi-rotary two-fold capacity hook.

In addition, the sewing machine comes with enhanced functions such as the feeding frame with a higher lift and the direct-drive machine head that provides excellent responsiveness and stop accuracy support the machine’s high-speed performance, thereby achieving increased productivity.Main applications

This sewing machine can be used for a broad range of sewing such as attaching small parts, ruffling curtains and attaching labels.

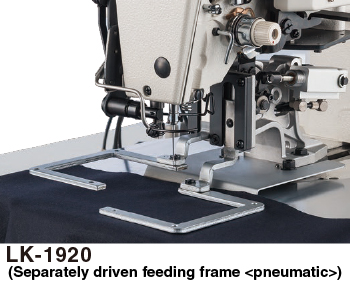

Intermediate presser that securely clamps the material (LK-1920)

The machine is provided as standard with an intermediate presser to prevent the material from flopping,thereby promising beautiful seams. Since height and stroke of the intermediate presser can be adjusted, quick responsiveness to changes in material thick or th number of layers materials is ensured.

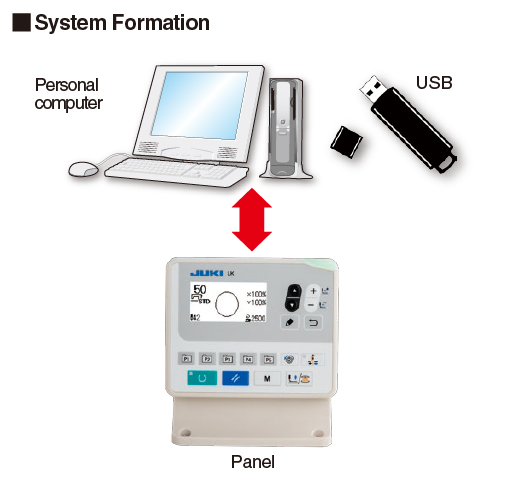

Function-rich easy-to-use operation panel

- Functions such as the sewing speed and bobbin thread counter can be easily set on the operation panel by entering desired setting values. Cycle sewing that combines patterns can be registered. In addition, the automatic correction function eliminates distortion of a pattern when enlarging or reducing it.

- Standard sewing patterns can be assigned to pattern keys P1 to P50. Any of the sewing patterns assigned to the P1 to P25 pattern keys can be activated with a touch of the corresponding key.

This means that workability is improved by assigning 25 sewing patterns that are most frequently used to those pattern keys. - As many as 99 different cycle sewing patterns, each of which combines a maximum of 99 different sewing patterns, can be stored in the memory.

Programming software for

computer-controlled sewing machinesOptionUse the pattern creation software PM-1 (separately available) to create pattern data. With the PM-1, data can be created with ease using the general-purpose personal computer.

Basic performance

The maximam sewing speed of 2,500 sti/min is achieved

The sewing machine achieves the highest-level sewing speed, 2,500sti/min, among shape-tacking machines, contributing to the achievement of shortened cycle time.

Frequency of bobbin thread changing is decreased

The sewing machine is provided as standard with a semi-rotary, two-fold capacity hook.

As a result, the frequency of handsome replacement of bobbin thread is decreased.

In addition, this hook allows the sewing machine to demonstrate its capability of sewing with thick thread.Sewing capability is improved

The range of applicable count of thread is widened to improve responsiveness to the sewing of heavy-weight materials. This improvement contributes to the enhancement of sewing capability.

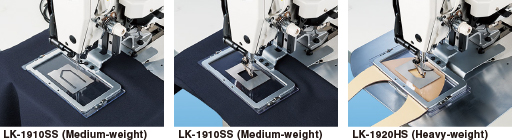

The sewing machine comes in two different types, i.e. the midium-weight materials sewing type (S) and the heavy-weight materials sewing type (H). You may select either one according to the application.Sewing area that supports a broad range of applications

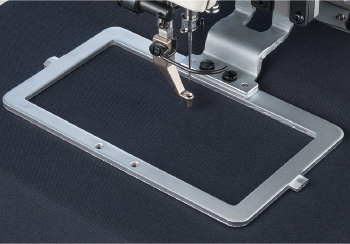

The sewing machine is provided with a wide sewing area of 60mm (length) × 100mm (width). As a result, the sewing machine responds to a wider range of applications such as attaching name labels and small parts, ruffling curtains, sewing ends of jeans belts and attaching labels.

The feeding frame type can be selected to match the use of the machine in your work

Two different feeding frame types are available, i.e., the monolithic type (electromagnet-driven) and the separately-driven type (pneumatically-driven) that has separate right and left frames. You may select the best-suited type of the feeding frame according to the application and work.

*The monolithic type (electromagnet-driven) is provided with the manual pedal that allows the feeding frame to be lifted/lowered according to how the pedal is depressed.

Specification

| Model name | LK-1910 | LK-1920 | ||||

|---|---|---|---|---|---|---|

| Application | Medium-weight | Heavy-weight | Medium-weight | Heavy-weight | ||

| Max.sewing speed | 2,500 sti/min* (when stitch length is 3mm or less) | |||||

| Sewing area | 60mm (L) × 100mm (W) | |||||

| Stitch length | 0.1mm~10mm (0.1mm step) | |||||

| Needle bar stroke | 41.2mm | |||||

| Lift of the feeding frame | Max. 22mm (electromagnetic) / Max. 25mm (pneumatic) | |||||

| Lift of the intermediate presser | - | 18mm | ||||

| Strock of the intermediate presser | - | Standard 4mm (0mm and 4mm~10mm) | ||||

| Needle | DP×5 (#14) | DP×17 (#18) | DP×5 (#14) | DP×17 (#18) | ||

| Hook | Double-capacity shuttle hook | |||||

| Feed motion work clamp foot | Max.20,000 stitches | |||||

| Standard sewing patterns | No.50, No.51, No.52 | |||||

| Number of patterns that can be input | 200 patterns | |||||

| Enlarging / Reducing facility | 20~200% (1% step), (by increasing the stitch length) | |||||

| Bobbin thread counter | Provided as standard (Up / down method) | |||||

| Memory medium | Memory /EEP-ROM | |||||

| Lubricating oil | JUKI New Defrix Oil No.2 (equivalent to ISO VG32) | |||||

| Sewing machine motor | AC servomotor (direct-drive system) | |||||

| Power consumption | Single - phase, 3 - phase 200~240V / 380VA | |||||

| Weight | Machine head (include motor) 46kg, control box 5kg | |||||

*sti/min is the abbreviation for "stitches per minute"

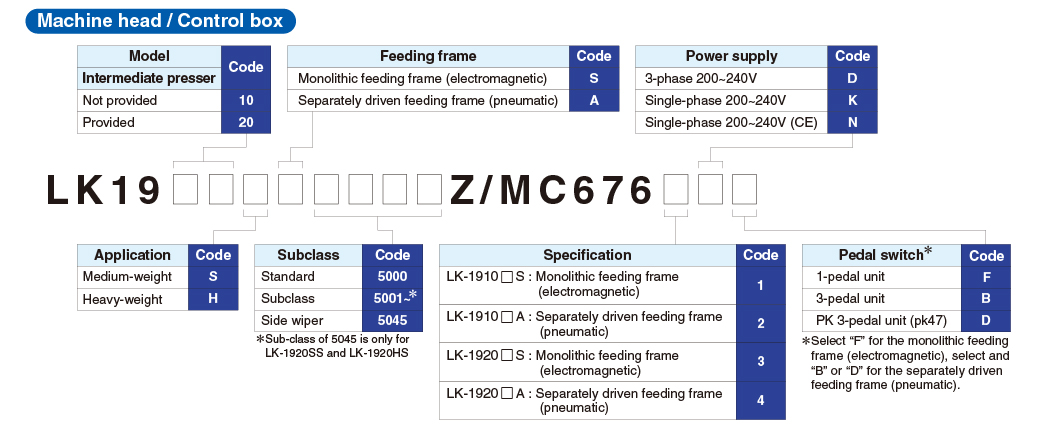

When you place orders

Gauge

LK-1910SS

LK-1910SA

LK-1910HS

LK-1910HA

LK-1920SS

LK-1920SA

LK-1920HS

LK-1920HA

| Guage | NEEDLE HOLE GUIDE | INTERMEDIATE PRESSER (FOR LK-1920 ONLY) |

TENSION CONTROLLER NO.3 (AIR SPECIFICATION) |

SHUTTLE RACE RING | |||

|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|||

| - | P/N | Remarks | P/N | Remarks | P/N | P/N | Remarks |

| B2426284M00 | A=1.6 B=2.6 With relief slit S type Standard |

B1601210D00A | A=2.2 B=3.6 C=38.5 S/H type Standard Intermediate presser A |

B50192220B0 | 14103253 | Shuttle race ring A 0.8mm | |

| 14109607 | A=2.3 B=4.0 Without relief slit H type Standard |

B1601210D0BA | A=2.7 B=4.1 C=38.5 Intermediate presser B |

14103352 | Shuttle race ring B 1.3mm S/H Specification Standard |

||

| D2426284C00 | A=1.6 B=2.0 Without relief slit For fasion and knit garments |

B1601210D0CA | A=3.5 B=5.5 C=38.5 Intermediate presser C |

14103659 | Shuttle race ring C 1.7mm | ||

| 14224307 | A=2.0 B=3.0 Without relief slit | B1601210D0E | A=1.6 B=2.6 C=37 Intermediate presser E |

B1817210DA0 | Shuttle race ring D 1.9mm | ||

| B242628000D | A=2.5 B=3.5 Without relief slit | B1601210D0FA | A=2.2 B=3.6 C=41.5 Intermediate presser F |

||||

| D2426MMCK0C | A=3.0 B=4.0 Without relief slit | ||||||

| OP | FEED PLATE BLANK | INVERTING CLAMP UNIT | SILICON OIL TANK | DISK RASING DEVICE ASM. | NEEDLE COOLER ASM. | FEEDING FRAME BLANK | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

||||

| - | P/N | Remarks | P/N | Remarks | P/N | Remarks | P/N | P/N | P/N | Remarks |

| 14120109 | Without knurl / without processing | 01570233 | FU-02S Magnet type presser |

B92118500A0 | Separately procure the following: B1131850000C x1: Stay for tank SS7110840SP x2: Fixing screw |

14224760 | 14225056 | B2553210D0A | Solid type geeding frame/ With knurl | |

| 14120307 | With knurl / without processing | 01570241 | FU-02L Presser air type |

2553210D0B | Solid type geeding frame/ Without knurl | |||||

| B2554210D0A | Separate type feeding frame/ Without knurl | |||||||||

| B2554210D0B | Separate type feeding frame (right)/ With knurl | |||||||||

| B2554210D0C | Separate type feeding frame (left)/ With knurl | |||||||||