Lockstitch, Automatic Welting Machine

The machine is flexibly adaptable to the sewing of various pockets.

Machine time is reduced to provide increased productivity.

Product overview

Product features

Increased productivity

In addition to the high-speed machine head with a maximum speed of 3,000 sti/min, faster movement (jump and forwarding) of the clamp foot achieves a shorter machine time.

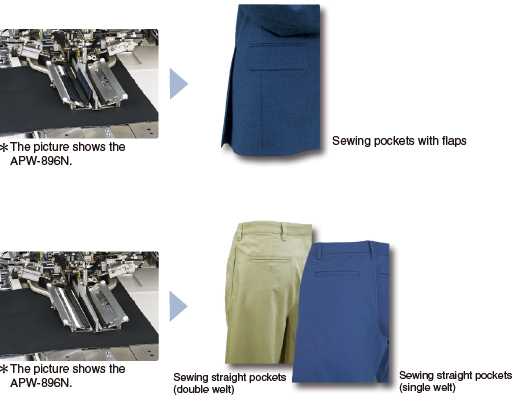

The sewing of straight pockets (with flaps) on suits, jackets and pants

(APW-895N/896N)The machine supports the sewing of straight pockets (with flaps) on suits, jackets and pants.

Double-/single-welt sewing can be changed over by the simple touch of a key on the operation panel.

Increased adjustable range of sewing lengths (min. 18mm to max. 220mm)

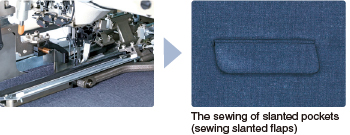

The sewing of slanted pockets (for sewing slanted flaps).(APW-896N)ONLY JUKI

In addition to the APW-895N's functions, the APW-896N supports the sewing of slanted pockets (for sewing slanted flaps).

The world's first computer-controlled sidewise cutting position of the corner knives enables easy adjustments of the knives simply by operating the panel.

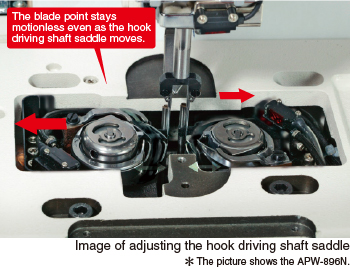

Time required for setup changing is substantially shortened

- The machine is equipped with a simple gauge changing mechanism which enables the changing and adjustment of the position of the hook driving shaft saddle from the top of the bed without tilting the machine head. The time required to change a needle gauge is less than a half of that required by conventional machines.

- The position of the folding plate and needle does not change even when double-/single-welt sewing is changed over. This means that the folding plate does not need any adjustment.

- The machine is provided as standard with a micro-adjusting function for adjusting the clamp foot position. This enables both accurate and quick adjustments of the welting width.

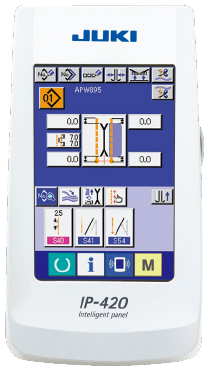

Highly-visible and easy-to-use

large color LCD touch-panel (IP-420)The graphic display and touch panel on the large color LCD help dramatically increase ease of use. Basic operations are carried out with the graphic screen and pictogram buttons. Guidance messages are given in your selected language.

External mediuma

Now the USB-ready main body of the sewing machine uses many different kinds of media

The memory storage capability of the main body of the sewing machine has been dramatically enhanced. Now the USB-ready main body of the sewing machine uses many different kinds of media. In addition to the Compact Flash card, the main body of the sewing machine is provided as standard with a USB connector. Now, data can be input/output to/from various kinds of media (SD (Secure Digital Card), CF (Compact Flash), SM (Smart Media) etc.) by means of a USB thumb device and a card reader.

Basic performance

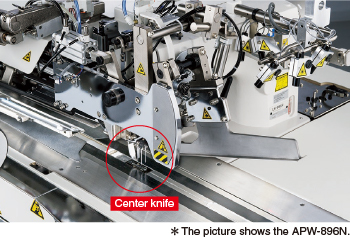

Increased sharpness of the center knife

An independently driven (speed can be changed) stepping motor is adopted for the center knife.

The center knife therefore remains unaffected by the sewing speed and cuts more sharply and cleanly. In addition, the knife shape is improved to prevent bending and demonstrates increased sharpness when an elastic material is being sewn.

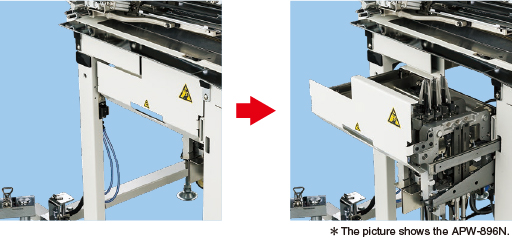

The corner knives are easily adjustable

The corner knives, which can be drawn out in the entire knife unit is adopted. The knives are easily adjusted and can also be changed with ease. The slim corner knife cover helps reduce material thrusting, thereby achieving material cutting with accuracy.

Newly developed stacker which is able to handle small articles

Two kinds of stackers are available; i.e., clamp bar stacker (SP-46N) and roller stacker (SP-47N). With the stacker, the machine is able to handle materials with a shortest distance of 250 mm from its edge to the pocket. A stacking sensor is also provided as standard to prevent stacking errors.

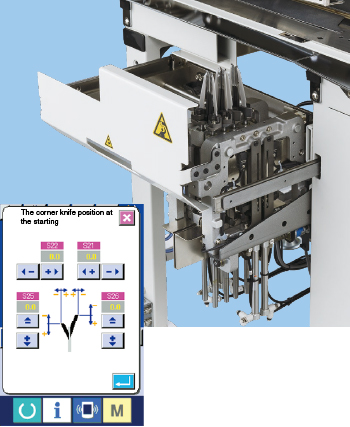

The world's first "corner-knife cutting adjustment" through the operation panel is achieved

There are many different kinds of welting patches in terms of specifications and materials. The corner knife cutting at the corner part of a welt needs fine adjustments. This can now be easily adjusted in 0.1 mm steps only through the operation panel since the corner knife comes with "computer control of the cutting position" and an "independent right- and left-blade lifting/lowering" mechanism. Fine adjustments of the amount of knife cutting to the stitch can be done both in the crosswise and lengthwise directions, not through the use of a tool, but simply by operating the operation panel. This substantially reduces the adjustment time and finishes high-quality welt.

Equal stitch-length right/left backtacking function is installed

The machine comes with an added function for equalizing the right and left backtack stitch length for the sewing of slanted pockets. This function helps improve the backtack seam quality.

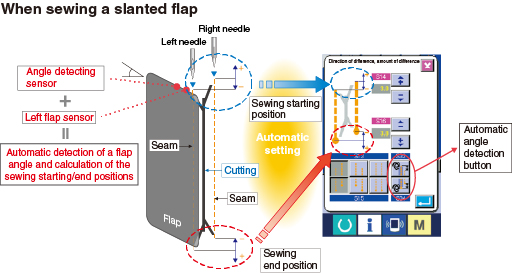

The machine is provided as standard with the "automatic left-flap angle detecting function"

By pressing the automatic angle detection button on the operation panel when sewing a left flap, the two sensors detect the flap angle to adjust the sewing starting (sewing end) position of the right and left needles when sewing a left flap.

*This function is provided as standard only on left-flap sewing.

*When automatic detection finds a difference of less than 0.5 mm, parallel stitching is performed.

*For the sewing of single welt, the flap-angle detecting sensors cannot be used. Only the flap sensor can be used.Automatic left-flap angle detecting function (APW-896N)

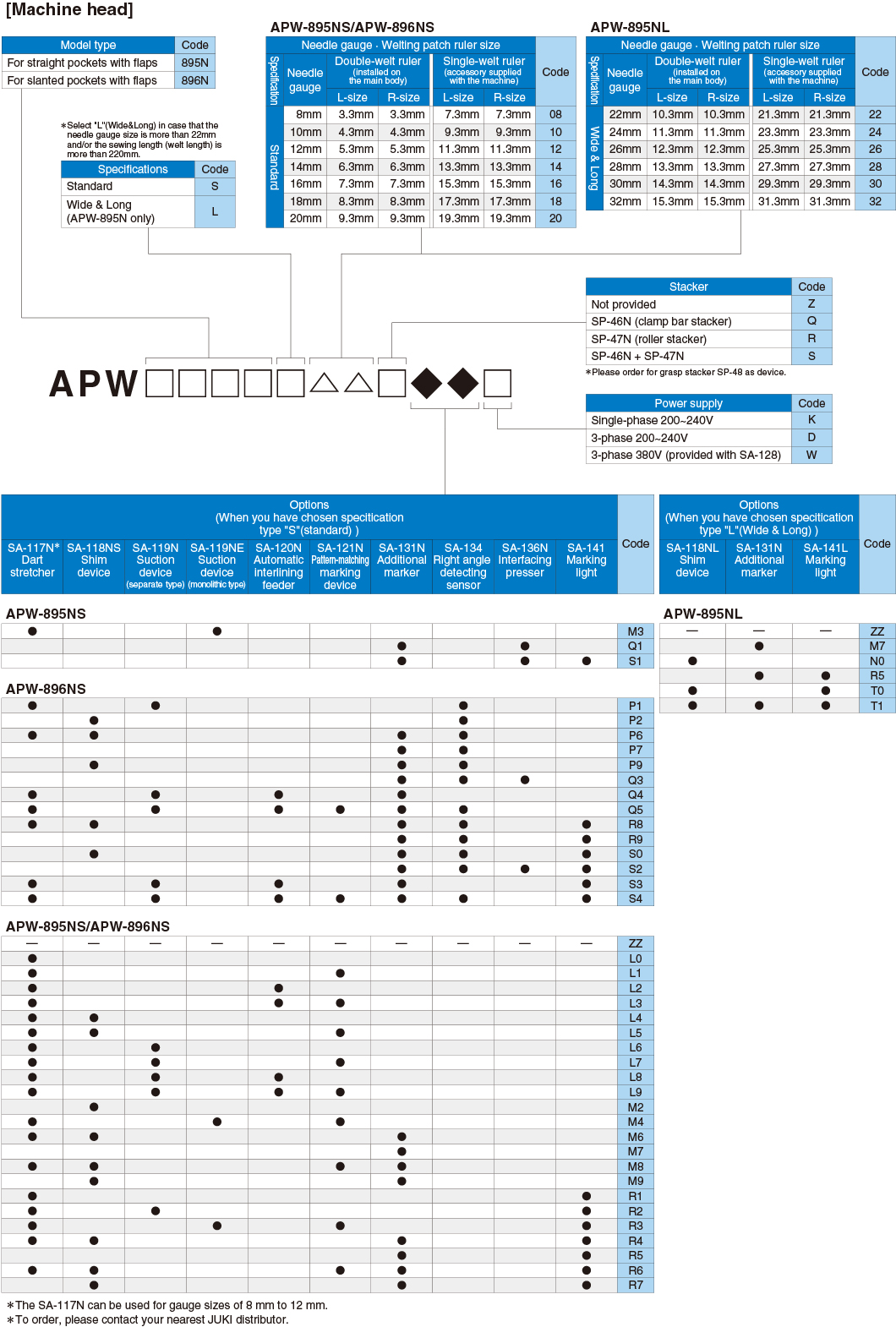

Specification

| Model name | APW-895N | APW-896N | ||||

|---|---|---|---|---|---|---|

| Flap type | Rectangular flap | Rectangular / Slanted flap | ||||

| Sewing speed | Max. 3,000 sti/min (1,000~3,000 sti/min)* | |||||

| Kind of welts | Parallel double welt, parallel single welt (with/without flaps) |

Parallel double welts, parallel single welts, slanted double welts, slanted single welts, trapezoidal sewing (with/without flaps) |

||||

| Stitch length | Standard 2.5mm (2.0~3.4mm) | |||||

| Stitch length (fastening stitching) |

Condensation stitching: Standard 1.0mm (0.5~1.5mm) Back-tack stitching: Standard 2.0mm (0.5~3.0mm) *Changeable between condensation / back tack stitching |

|||||

| Corner-knife cutting adjusting method |

Mechanical adjustment | Electronic adjustment | ||||

| Needle | ORGAN DP × 17 Standard #16 (#14~#18), SCHMETZ 190R Standard #100 (#100~#110) | |||||

| Thread | SPUN #60 (recommend) | |||||

| Hook | Vertical-axis 1.7-fold capacity hook | |||||

| Number of independent sewing patterns |

99 patterns (999 patterns when a CF memory card is used) | |||||

| Number of cycle sewing patterns |

20 patterns | |||||

| Number of alternate sewing patterns |

20 patterns | |||||

| Machine head | 2-needle, lockstitch machine (LH-895) | 2-needle, lockstitch machine with organized split needle bar (LH-896) |

||||

| Cloth feeding system | Driven by a stepping motor | |||||

| Power requirement | Single-phasae 200~240V, 3-phase 200~380V 50Hz / 60Hz | |||||

| Power consumption | 350VA | |||||

| Compressed air / Air consumption |

0.5MPa, 40dm³/min (ANR) | |||||

| Weight | 238.5kg | 259.0kg | ||||

| Dimensions | 1,095mm(W)×1,500mm(D)×1,200mm(H) (Width 1580mm = Stacker included) (Height 1800mm = Thread stand included) |

|||||

| Model name | With / Without (corner knife and center knife) |

Sewing length (welt length) | Needle gauge (mm) | |||

|---|---|---|---|---|---|---|

| APW-895NS | Without | Min. 18mm~Max. 220mm (settable in increments of 0.1mm) | 8, 10, 12, 14, 16, 18, 20 | |||

| With | Min. 35mm When a solenoid valve is used: Min. 21mm *For a needle gauge width of 14mm or more, the minimum sewing length is 50mm. |

|||||

| APW-895NL | Without | Min. 18mm~Max. 300mm (settable in increments of 0.1mm) | 22, 24, 26, 28, 30, 32 | |||

| With | Min. 50mm~Max. 250mm (settable in increments of 0.1mm) | |||||

| APW-896N | Without | Min. 18mm~Max. 220mm (settable in increments of 0.1mm) | 8, 10, 12, 14, 16, 18, 20 | |||

| With | Needle gauge 12mm or less: Min. 21mm~Max. 220mm Needle gauge 14mm or more: Min. 50mm~Max. 220mm |

|||||

*"sti/min" Stands for "Stitches per Minute."

When you place orders