Approach to Environment of Group

approaches of the group companies

Taking measures for environmental legal restraints at JUKI (VIETNAM) CO., LTD.

This company introduced a treatment system to improve water quality in April 2016 after sewagecontaining water discharged from the second plant of JUKI (VIETNAM) CO., LTD. was found to exceed its reference values. This company has also put segregation management into effect by assigning numbers to different types of hazardous waste individually for easy visualization and charting.

Processing system

at the second plant

of JUKI (VIETNAM)

CO., LTD.JUKI

Place for trash

Place for hazardous waste

Emissions of phosphorus (P)

Promoting and reinforcing environmental education at JUKI (SHANGHAI) INDUSTRIAL CO., LTD.

JUKI (SHANGHAI) INDUSTRIAL CO., LTD. conducts a “tree-planting day” campaign every March to improve consciousness of the benefits of beautifying the factory environment. Besides this, the company works to reduce the generation of garbage by performing a one-day “eat up” campaign once a month at its cafeteria. The campaign typically saves up to 136 RMB a day with the full participation of 680 people on the day.

- Tree-planting Day at JUKI (SHANGHAI) INDUSTRIAL CO., LTD.

- Participants

Acting for reducing the packing materials at SHANGHAI JUKI SEWING MACHINE CO., LTD.

SHANGHAI JUKI SEWING MACHINE CO., LTD. improved its method for packing circuit boards in the stage of materials and parts procurement. This company used to place circuit boards individually into antistatic bags and transported them in corrugated cardboard, packaging materials that were finally discarded as waste.

To eliminate waste, the company abolished the antistatic bag and replaced it with a newly designed antistatic tray that serves as a returnable case. The economic benefit resulting from the reduced emissionsand waste is estimated to reach 8,170 RMB annually.

While the improvement is currently adopted for the company’s main Circuit Board only, the company will develop similar solutions for other types of Circuit Boards horizontally.

Before implementation: the antistatic bag becomes waste material.

After implementation: the electrostatic tray can be put into a line as is.

Acting for preventing environmental pollution at JUKI (SHANGHAI) INDUSTRIAL CO.,LTD.NINGBO BRANCH

JUKI (SHANGHAI) INDUSTRIAL CO.,LTD.NINGBO BRANCH used to fill its industrial wastewater into drums and outsource its treatment. Then it introduced treatments to change its internal treatment methods and reduce costs. The company also managed to achieve values substantially below the drainage regulation by thinking about the introduced equipment creatively in-house. To publicize its approach to the environment, the company released a video outlining the details of this disposal method to its customers and related institutions as well as its employees.

They input the absorbent cotton to the precipitate pond.

Final effluent treatment equipment

Adapting to the environmental laws at JUKI INDUSTRIAL EQUIPMENT TECHNOLOGY CORPORATION

In response to the effectuation of the CFC emissions law in April 2015, an engineer at JUKI INDUSTRIAL EQUIPMENT TECHNOLOGY CORPORATION acquired qualification for handling second-class refrigerant freon. The company also manages the usage conditions of its refrigerant chlorofluorocarbon equipment and performs regular checks on the equipment in-house.

Regular checks on refrigerant chlorofluorocarbon (CFC) equipment

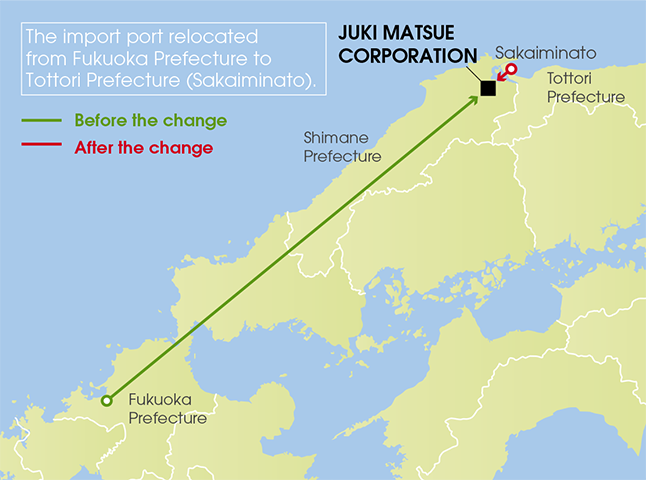

Making efforts to reduce CO2 emission at the physical distribution stage at JUKI MATSUE CORPORATION

JUKI MATSUE CORPORATION is reducing CO2 in response to a change of the import port and the adoption of the “modal shift ※1.” The company reduced the annual quantity of consumed oil by 1,375ℓ and reduced the annual amount of general CO₂ emissions by 3,555kg. These values together represent a total reduction of 88% per year, a higher reduction than ever before achieved.

*1: “Modal shift”: a change in transport means from line transport of passengers and goods by truck to transport by train and ships in order to reduce CO2 emission through the scale benefit of mass transport.

Communicating with the local community on environmental issues at the OHTAWARA PLANT

JUKI CORPORATION OHTAWARA PLANT participates in a cleanup of the drain together with people from neighboring districts to clean the environment and deepen communication. The OHTAWARA PLANT holds a JUKI briefing on the status of drainage every November. Administrators from all of the neighboring districts are invited to the factory to attend. The OHTAWARA PLANT also receives a report on the indepth result of drainage analyses from persons in charge of the Life Environment Department of the local city office and builds a relationship with the administrators based on mutual communication.

Scene of cleaning the drain

Making efforts to reduce CO2 emissions in the stages of production at SUZUTAMI PRECISION INDUSTRY CO., LTD.

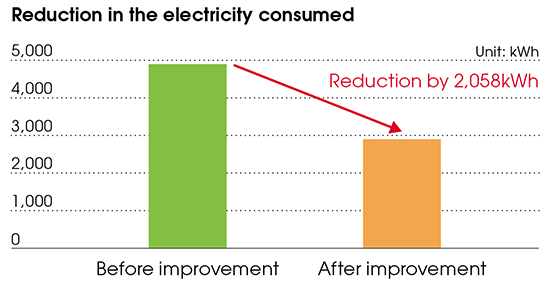

To save energy and increase productivity, SUZUTAMI PRECISION INDUSTRY CO., LTD. has used a subsidy to cover investment costs for the renewal of six of the airconditioning machines in the factory to energy-saving types. This company now operates 23 energy-saving air-conditioning machines accumulated from the installation of the first machine in 1991. These six new air-conditioning machines are energysaving, silent, and equipped with easy-to-clean filters. A factory space is also widened because the main unit is compact. These compound effects enabled a reduction in the electricity consumed by 2,058 kWh a month.

Before introduction

After introduction