SMT-related systems

What is an SMT-related system?

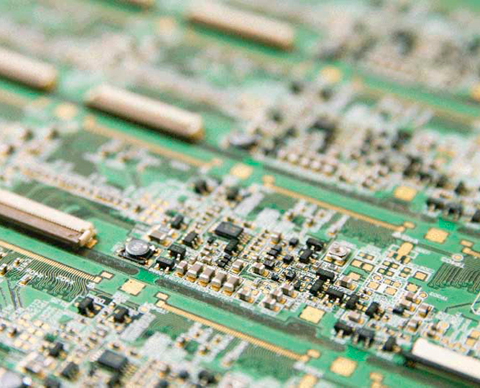

Electronic circuit boards are incorporated in virtually all products, from appliances and electronic devices to industrial robots and the machines that produce them. We can think of the electronic circuit board as the brain of a product.

An “SMT-related system” is a system used to fabricate an electronic circuit board.

Procedures to fabricate an electronic circuit board up to completion

Screen printer

RP-1

Before a mounter places a component on a circuit board, this machine applies a glue-like “solder” for fusion with the board.

This machine uses a thin stencil called a screen to print the “solder” on the board in a single operation.

Before a mounter places a component on a circuit board, this machine applies a glue-like “solder” for fusion with the board.

This machine uses a thin stencil called a screen to print the “solder” on the board in a single operation.

Inspection machine

RV-2

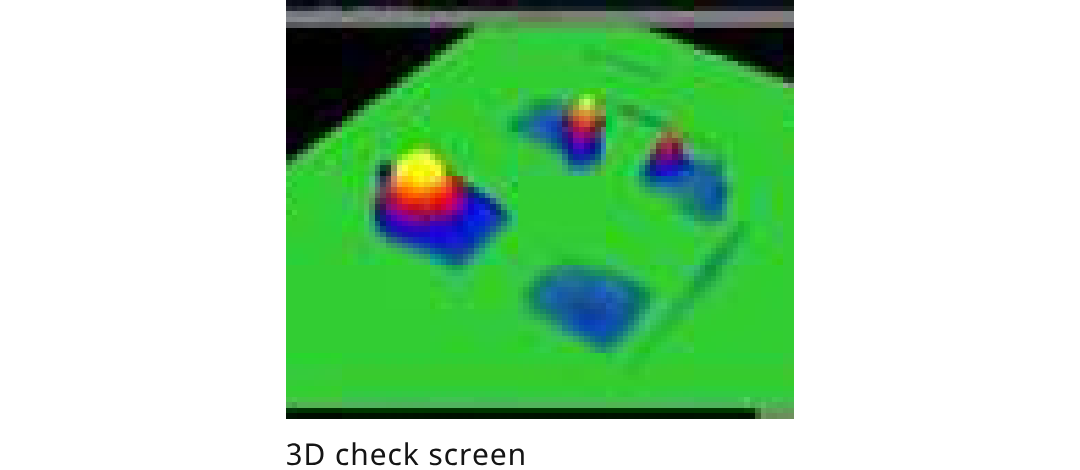

This machine analyzes the applied solder from two or more directions to check for differences in the placement, area, height, and amount of solder.

This machine analyzes differences in illumination and in shadows cast by eight-direction lighting and generates 2D&3D images to check the printed state.

This machine analyzes the applied solder from two or more directions to check for differences in the placement, area, height, and amount of solder.

This machine analyzes differences in illumination and in shadows cast by eight-direction lighting and generates 2D&3D images to check the printed state.

Mounter

RS-1R

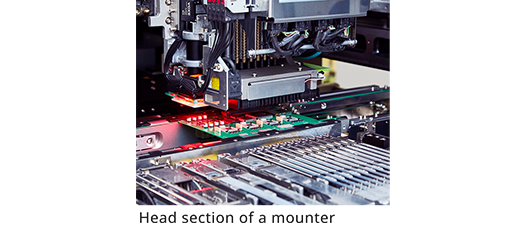

The components mounted on a board come in various shapes and sizes. This machine places the components at high speed with great accuracy.

The mounter has a section for picking up components called a head. Mounters come in two types. One is specialized in the placement of extremely small components at high speed. The other is a general-purpose (flexible) mounter capable of placing components of many different types.

This mounter can be used with two or more machines connected to each other.

The components mounted on a board come in various shapes and sizes. This machine places the components at high speed with great accuracy.

The mounter has a section for picking up components called a head. Mounters come in two types. One is specialized in the placement of extremely small components at high speed. The other is a general-purpose (flexible) mounter capable of placing components of many different types.

This mounter can be used with two or more machines connected to each other.

Inspection machine

RV-2-3DH

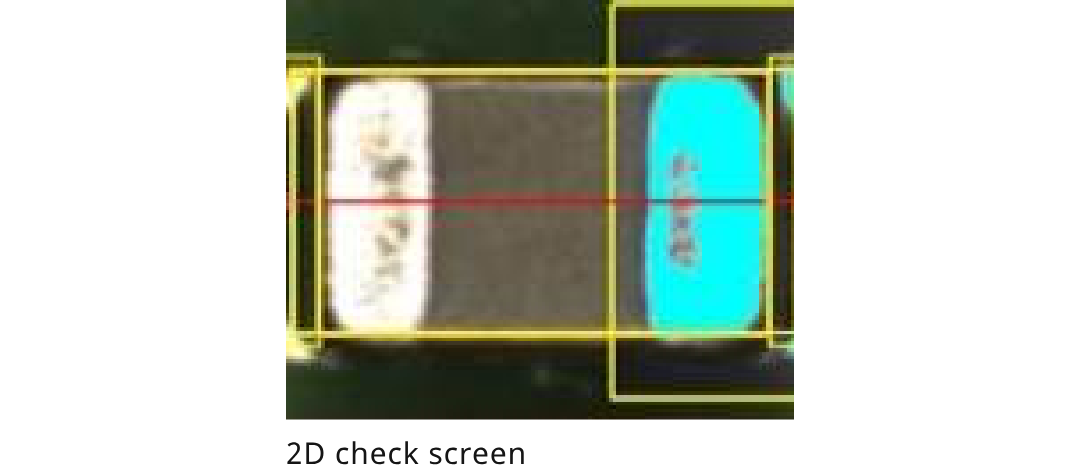

Using 3D and 2D images taken with a camera, parts are checked for defects, misalignments, floats, character recognition, soldering, etc., to determine whether the board is good or bad.

Using 3D and 2D images taken with a camera, parts are checked for defects, misalignments, floats, character recognition, soldering, etc., to determine whether the board is good or bad.

Insertion machine

JM-100

This machine automatically mounts large-sized components that normally must be placed by hand (difficult-to-automate placement) and components with special shapes.

This machine automatically mounts large-sized components that normally must be placed by hand (difficult-to-automate placement) and components with special shapes.

Clinch unit

Clinch unitReflow oven

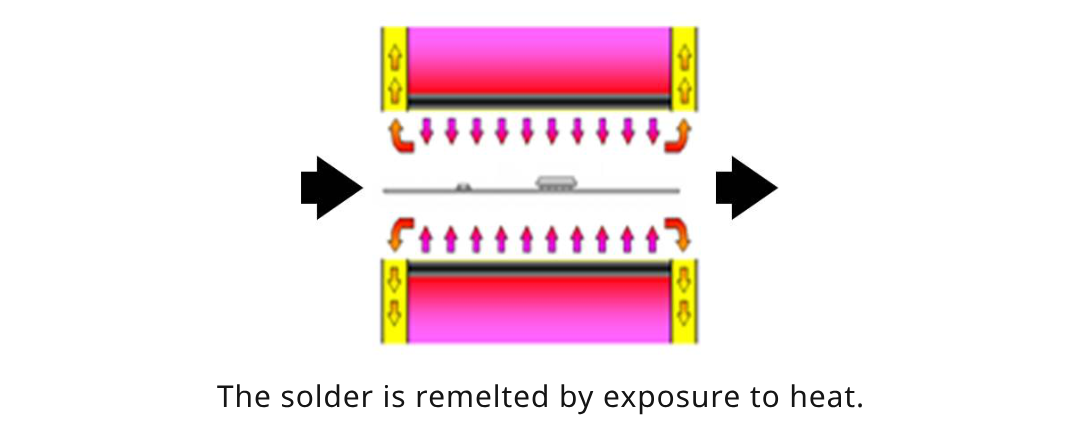

This machine mounts components to a soldered board by placing the board into a solder bath or hot airflow (about 140℃ – 250 ℃) to remelt the solder. The components are mounted on the melted solder and the board is recooled.

Inspection machine

RV-2-3DH

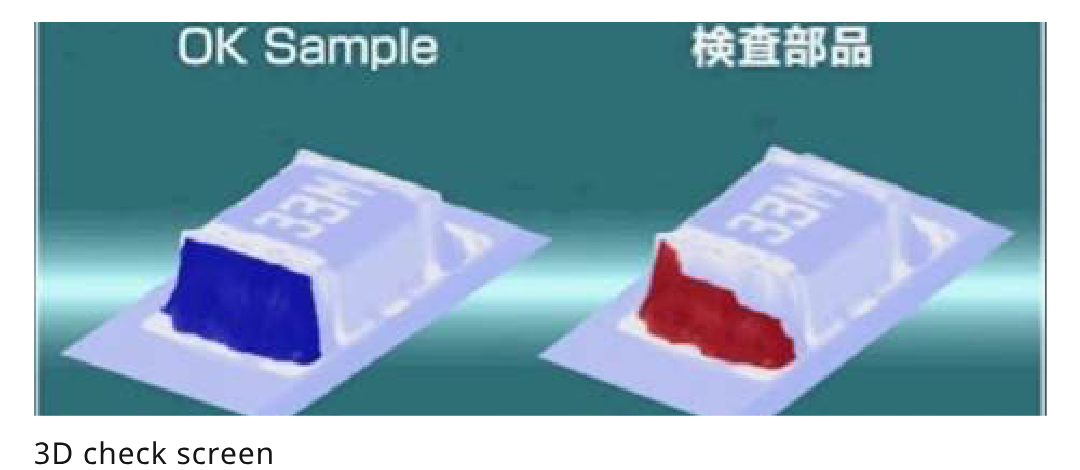

This machine analyzes the three-dimensional shape of the completed board and compares the shape against the specification based on the outlines, heights, and brightnesseses of the components and solder. It then judges whether the board is OK or NG (no good) based on the analysis.

The 2D check function is also workable.

This machine analyzes the three-dimensional shape of the completed board and compares the shape against the specification based on the outlines, heights, and brightnesseses of the components and solder. It then judges whether the board is OK or NG (no good) based on the analysis.

The 2D check function is also workable.

Completion of an electronic circuit board

New models

Lineup by category

JUKI website for SMT-related systems