Group Business

Contracted development and manufacturing business

Features and advantages of JUKI’s contracted development and manufacturing business

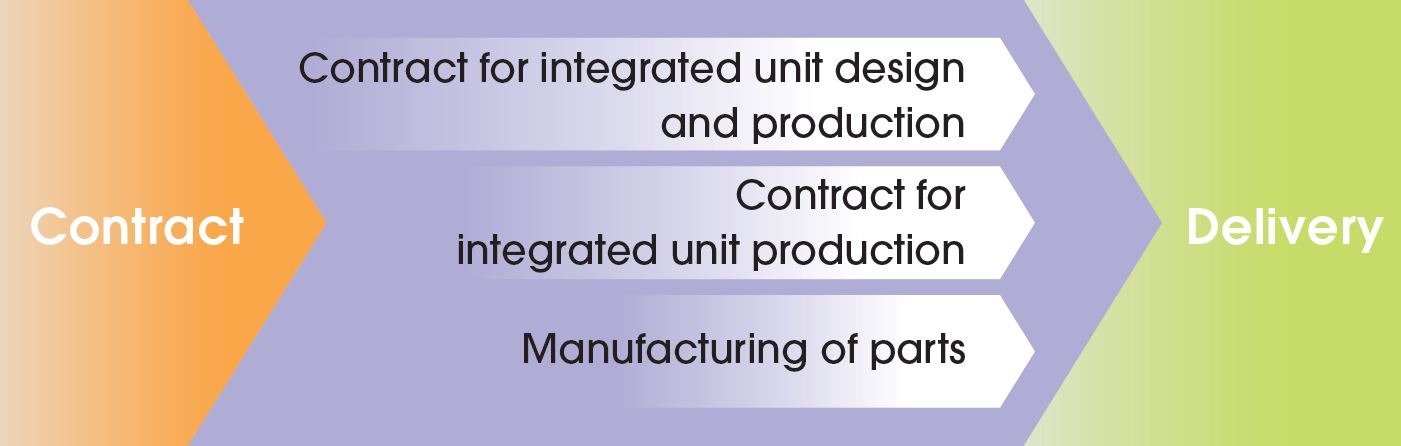

This business makes arrangements to contract with manufacturing companies for the development, manufacturing, machining, etc. of various products using the know-how in development, design, production, and production control that JUKI group companies have.

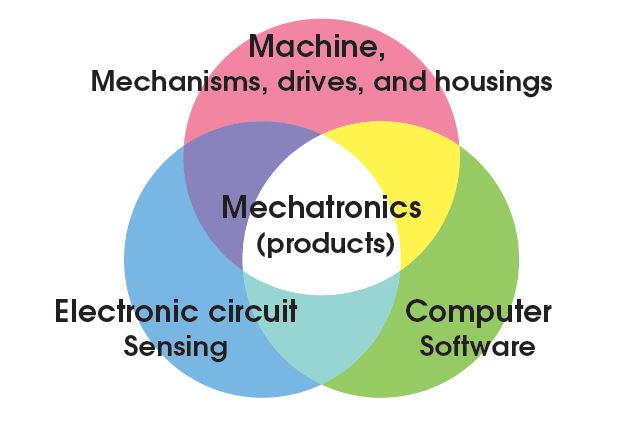

Enabling development and design of equipment control

These customer solutions enable the development and design of equipment control based on technologies developed in the mounter design and development process. Diverse human resources gathered from the fields of mechanical engineering, electronics engineering, and software combine flexible ideas to create new products.

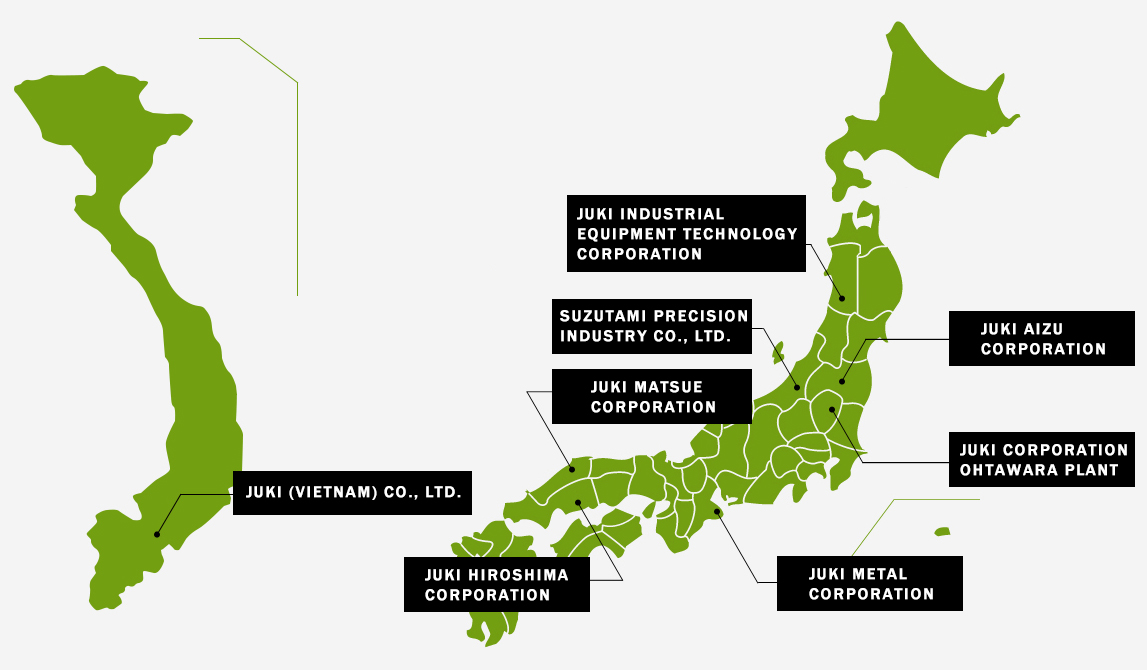

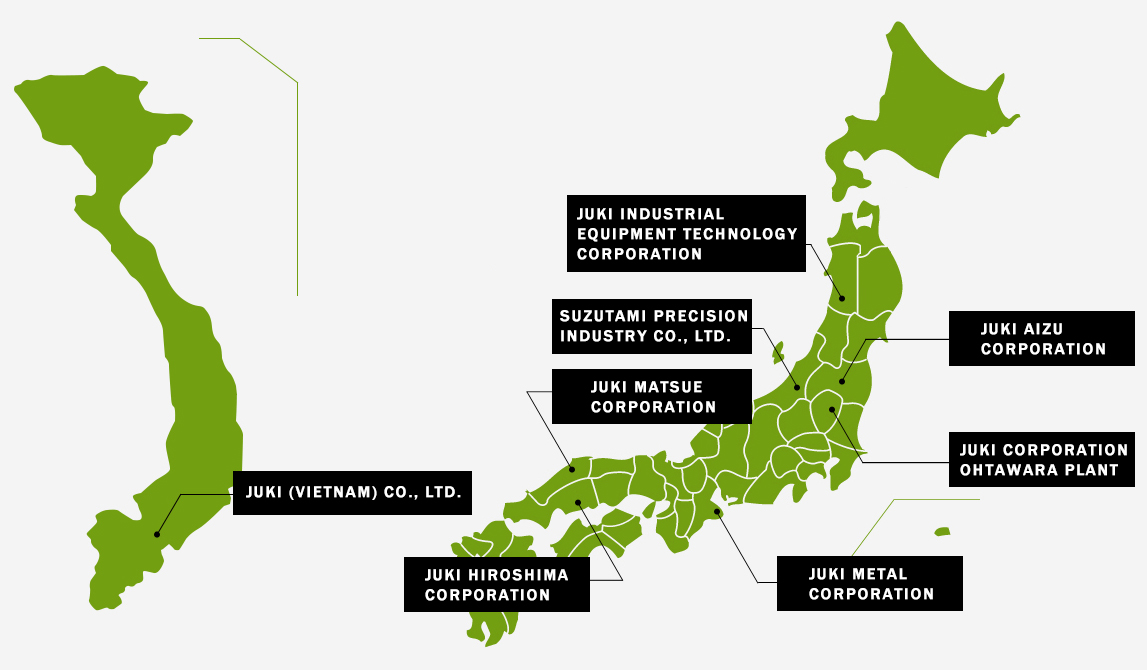

Gathering JUKI’s and the JUKI Group’s manufacturing (Monodzukuri) capabilities (development capacity and manufacturing capacity) together

All of the companies at JUKI’s manufacturing bases have acquired ISO9001 certification. They adopt scientific analytical methods based on JUKI’s more than 50 years of manufacturing

(Monodzukuri) experience and adhere to highly efficient practices with a commitment to eliminating waste. They also deliver high value-added production, good-quality manufacturing (Monodzukuri), and high-quality products.

Supplying high value-added products through full utilization of “people, equipment, method and materials” (Material→machining→assembly→finished goods)

Technicians who have acquired various national qualifications complete products by means of multi-selection manufacturing suitable for customer’s needs using a wide variety of technologies such as MC (Machining Center), casting, grinding, and painting. They also perform all of the processes from material procurement to manufacturing and assembly by means of a one-stop service.

Development capacity and manufacturing capacity

Productizing ideas by fusing the forte manufacturing technologies of our bases with something extra

Precision casting by lost-wax and MIM processes

Curved surfaces in three dimensions are difficult to form in the machining process. Now, with lost-wax and MIM processes, curved surfaces can be formed by monoblock casting. With these production systems, the

cost of products can be reduced in comparison with. In addition to standard irons, steels and

non-ferrous metals, we use titanium alloys, heat-resisting alloys, and cobalt alloy with vacuum casting equipment. About 80 different materials can be used in total.

Precision processing at the micron level

We can process materials at the micron level using machining centers, NC automatic boards, wire cuts, electro-discharge machining systems, grinders, and other equipment. We also have rich experience and know-how in the use of jigs and custom-designed knives made in-house for processing odd-shaped or difficult-to-cut materials.

Consistent manufacturing with presses, sheet

metal, welding, and painting

Our VE proposals minimize costs with applied know-how in blanking and bending and design along with advanced welding technology and painting processes. Large numbers of technicians with special grade qualifications for mechanical inspections work with the finest factory sheet metal and turret punch presses with perfect numerical value control to support high-quality production.

Business collaboration company

SLEEP BUSTER(Sold only in Japan)

Features of Sleep Buster

Supporting the driver’s safe run

The Sleep Buster is a device developed to reduce trafc accidents by preventing overwork driving.

A sensor pad attached to the driver’s seat monitors physiological signals in driver’s upper body second by second. Built-in algorithms assess the degree of driver fatigue and issue warning displays or sounds whenever the driver’s concentration or physical condition decreases or suddenly changes (e.g., when the driver drifts toward sleep). The driver’s stress, concentration, arousal, and fatigue can all be analyzed in more detail by downloading the sensor data to a personal computer using JUKI’s exclusive software.

DATA ENTRY SYSTEM(Sold only in Japan)

Features of Data Entry System

JUKI’s original information-processing system

A data entry system is a system for rapidly inputting large volumes of alphanumeric data.

Insurance companies, banks, and other organizations that process great deals of information are members of the information processing industry. JUKI is now developing equipment to enhance processing capabilities and reduce human error for these organizations. Foremost among their needs are the “protection of condential and personal information,” “more efficient image entry with help from OCR processing,” and “deliveryless system using high-speed communications infrastructure.”

Other menus