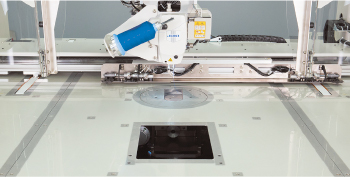

1-needle CNC sewing machine

(head turning type)

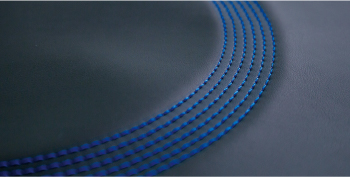

Best stitches in 360° for Car Seats, Bags and Air Bags

JUKI is launching the "AMS-251" its high-end 1-needle CNC sewing machine provided with a machine-head-turning mechanism.

The new model guarantees high-quality seams uniformly in every sewing direction.

Product overview

Product features

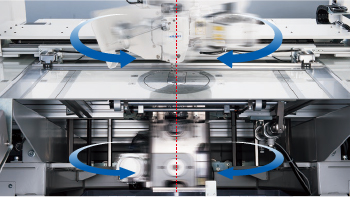

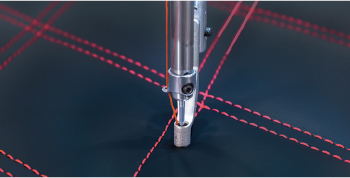

The machine-head-turning mechanism helps achieve high-quality seams uniformly in every sewing direction

JUKl's unique synchronization technology controls the machine head, hook and feed mechanism, thereby creating the most favorable seams.

In case of continuous circumference sewing, the sewing machine constantly detects the direction of sewing. As a result, consistent-quality seams are produced regardless of the direction of sewing.

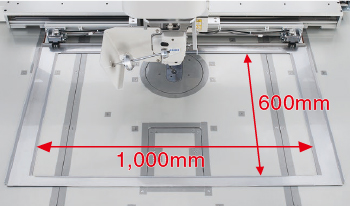

With its sewing area of "1,000 mm × 600 mm" the AMS-251 is best suited to the sewing of decorative stitches and large-size products

The sewing machine is ideally suited to the sewing of decorative stitches on car seats, luxury bags and school bags, but also to the sewing of large-sized products with zero design tolerance for irregular stitches. In addition, the sewing machine can be used for sewing two or more pieces of small products at a time.

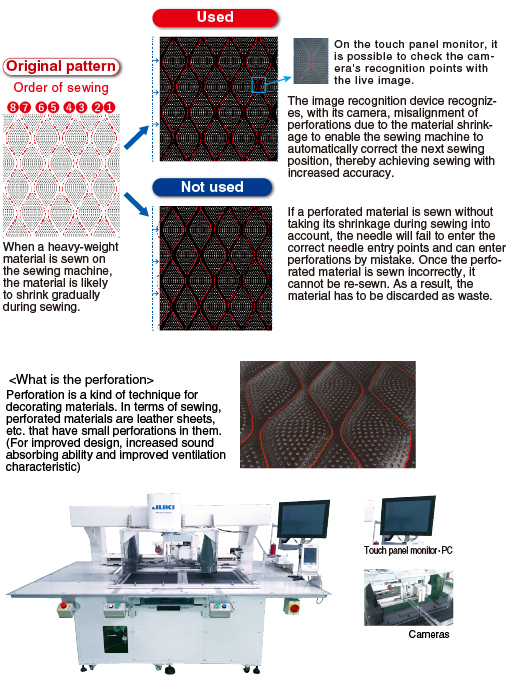

Perforation Camera System (optional)

Thanks to JUKl's original image recognition technology, this sewing machine enables sewing of hard-to-sew perforated materials as desired and produces beautifully-finished seams.

Basic performance

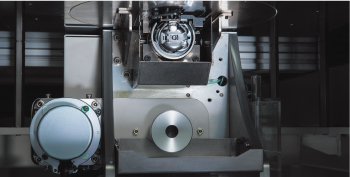

Machine head turning Slip ring system*1

Slip ring system has been adopted to the new machine-head turning mechanism. As a result, limitless turning of the machine head is enabled to allow the sewing machine to sew complicated patterns continuously.

*1 Rotating connector that is able to transmit power and electric signals from the stationary body to the rotating body

Machine head turning Cutting point needle

The cutting point needle can be used regardless of the sewing direction since the sewing machine constantly faces the sewing direction at its front.

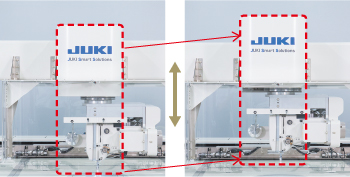

Machine head lifting function

Since thick materials, clamps, palettes with protrusions can be used, design will be expanded.

Multi-axis control technology

The multi-axis control technology used by JUKI are applied to simultaneously control six axes*2.

*2 Machine-head turning, Hook turning, Main shaft, Hook driving shaft (hook), X-axis feed, Y-axis feed

Horizontal-axis, 3 fold-capacity rotary hook

Adoption of the 3 fold-capacity hook helps reduce the frequency of bobbin replacement even when thick thread is used, thereby supporting sewing of large products.

Operation

The IP420 for the existing AMS Series models has been adopted for the new AMS model. In addition, the existing sewing pattern input software "PM1" is also applicable.

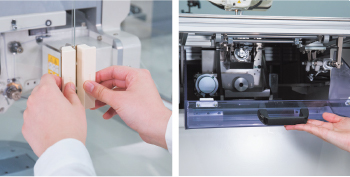

Safety cover

Opening and closing sensor is mounted to the turning-head cover and turning-hook cover to prevent the machine from starting when the cover(s) is opened and to automatically stop the machine if the cover(s) is opened while the machine is in operation.

Start button

A 2-handed start button has been adopted for safe, accurate start up. In addition, unintentional start up of the machine is prevented.

Bobbin replacement cove

Bobbin can be changed easily by opening the accessible cover without requiring the operator to reach under the machine to change the bobbin.

Specification

| Model name | AMS-251 | |

|---|---|---|

| Application | Medium - Heavy | |

| Sewing Area | 1,000 mm × 600 mm | |

| Max Sewing Speed | 2,500 sti/min* (for stitch length of 3 mm or less) | |

| Needle (at the time of delivery) | DP x17, #18 - 25 (#23) | |

| Thread | Nm 60/3 - 20/3 | |

| Hook | Rotary Hook, Horizontal - Axis, 3 fold - capacity | |

| Head Liftable | 50 mm | |

| Storage of pattern data | Main-body memory: Max. 33,000,000 stitches, 999 patterns (max. 50,000 stitches/ pattern) | |

| External Max. 50,000,000 stitches, 999 patterns (max. 50,000 stitches/ pattern) | ||

| Total weight | 950 kg | |

| Dimensions | 2,400 mm (W) × 1,800 mm (D) × 1,600 mm (H) | |

*"sti/min" stands for "Stitches per Minute"

| Pallet clamp recelver | Flxlng screws, washers | |||

|---|---|---|---|---|

| Accessory parts | 40181516 × 2 pcs |

SM5040855SN × 6 pcs WP0410516SD × 6 pcs |

||

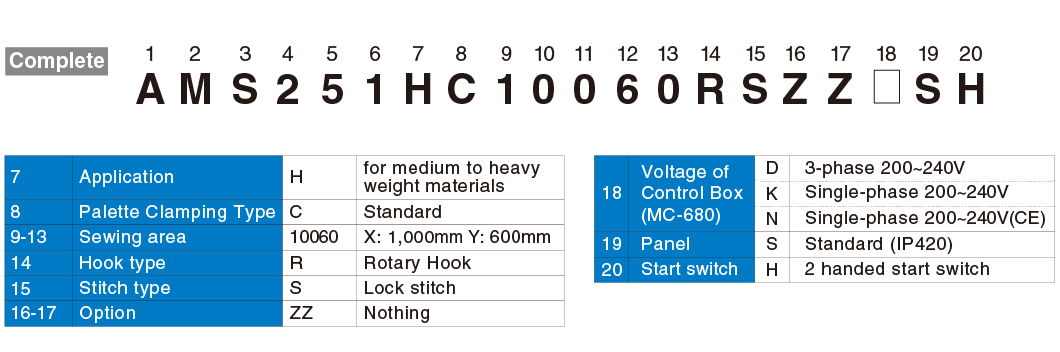

When you place orders

Gauge

AMS-251

| Guage | NEEDLE HOLE GUIDE | INTERMEDIATE PRESSER | |||

|---|---|---|---|---|---|

| Sewing spec. Needle size used | Figure |  |

|

||

| Thread count | P/N | Remarks | P/N | Remarks | |

| For medium to heavy weight materials #18 Nm100 |

#30~#20 | 14439400 | Φ2.0, OP | B1601210D00A | Φ2.2, OP |

| For heavy weight materials #18~#21 Nm100~130 |

#20~#8 | 14439509 | Φ2.3, OP | B1601210D0BA | Φ2.7 |

| For extra heavy weight materials #20~#23 Nm125~160 |

#8~#2 | 14439608 | Φ3.0 | B1601210D0BA | Φ2.7 |

| For extra heavy weight materials #23 Nm160 |

#8~#2 | 14439905 | Φ4.0, OP | B1601210D0CA | Φ2.2, OP |

* Needle wich is provided as standard (CN: GROZ-BECKERT 135×17 Nm160, Other than CN: DP×17 #23)