LZ-2290CF

![]()

Skip stitch detection device

With the skip stitch detection device (SD-29) included, the sensor detects stitching defects such as skipping and double stitching, which are particularly likely to occur on zigzag stitch sewing machines, and displays the error on the panel.

This eliminates the need for visual quality checks after sewing and allows defects to be detected on the spot.

(option)

Rotary-type active tension

It is possible to correct the thread tension according to sewing speed.

This allows upper thread tension to be corrected according to (1) sewing speed or (2) sewing conditions.

In addition, (3) by detecting the amount of remaining bobbin thread, the upper thread tension can be corrected according to the amount of remaining thread, thus realizing stable sewing.

Active presser

Pressing foot pressure can be set numerically on the panel according to the sewing speed.

This prevents jumping during high-speed sewing, and enables stable sewing of thin fabrics by correcting the pressing foot pressure according to sewing speed, thereby enhancing productivity.

(LZ-2290CF/AK156)

Multi-layered portion detection

By measuring the fabric thickness of flat and multilayered areas, sewing data (pitch, presser, sewing speed, thread tension, and number of stitches) can be set for each area.

When a multilayered area is detected, it automatically switches the setting data of thread tension, etc., to prevent stitch gathering at the multilayered portion.

(LZ-2290CF)

Digital feed mechanism

Vertically and horizontally-driven digital feed mechanism

Change in feed timing has been a time-consuming operation. For the LZ-2290C, however, feed timing can be changed with ease by operating the operation panel. It is therefore possible to set the feed timing so as to produce the seam quality (soft⇔standard⇔hard) that is suited to the process.In addition, the feed locus can be changed to that for preventing material slippage. With these improvement, the sewing machine provides further enhanced responsiveness to materials.

(LZ-2290CF)

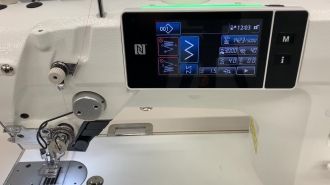

Sewing of diversified patterns

The horizontal feed mechanism is motor-controlled, enabling the machine to handle a variety of sewing shapes.

The sewing machine is provided as standard with 11 types / 20 patterns of basic stitch shapes.

Furthermore, up to 200 custom patterns can be stored, and data can be saved by process and item.

Even troublesome tasks, such as the process of skipping the stitching of the bone part of a brassiere, can be de-skilled by creating a pattern, leading to improved productivity.

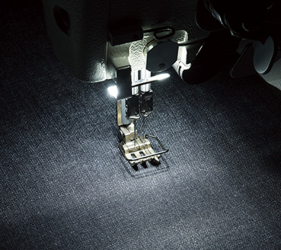

LED hand light

Reducing operator fatigue

For the LED hand light, the improved toning function with two additional colors (white / light bulb color) is provided.

The color can be adjusted according to the shade of the fabric, reducing eye fatigue of operators who spend long hours sewing.

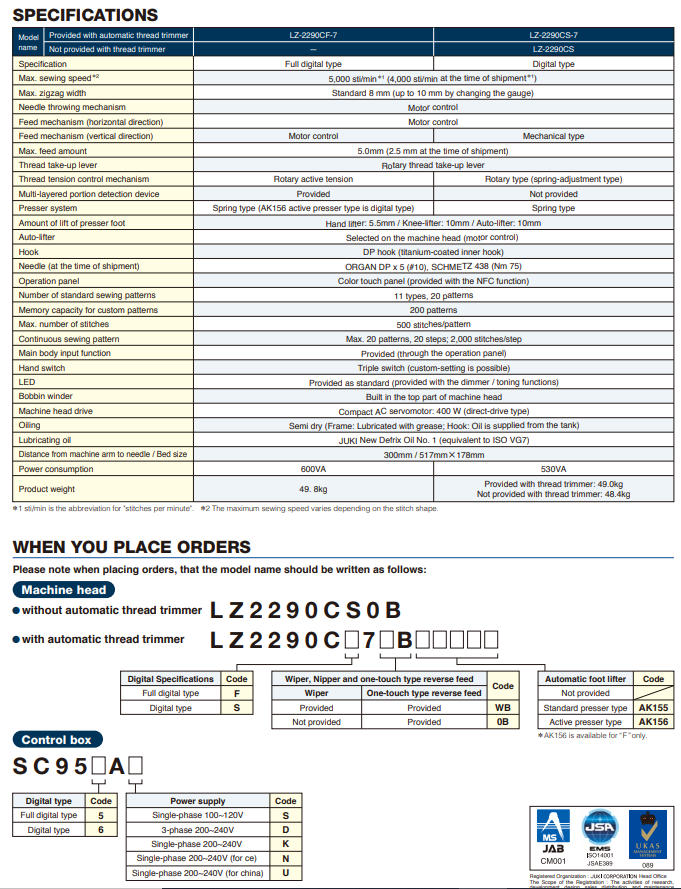

Specification