Direct-drive, high-speed, lockstitch sewing system

with automatic thread trimmer

Creation of “sewing”..

A state-of-the-art sewing system that revolutionizes the perfection for “sewing”.

Succeeding the traditionally required experience and instincts, digitalized setting capability in JUKI’s all new DDL-9000C digital sewing system presents the best sewing conditions everywhere and anywhere.

Product overview

Product features

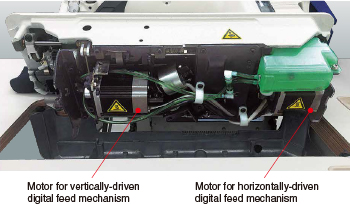

“Double digital feed mechanism” installedWorld first

Thanks to the world’s first vertically-and horizontally-driven digital feed mechanism, the feed dog height can be adjusted with ease according to the material fabric of product to be sewn, thereby improving seam quality.

Thanks to this digital feed mechanism, thread trimming is carried out with the feed dog lowered in the case the shorter-thread remaining thread trimming function is enabled. As a result, the clearance provided between the throat plate and the material is eliminated, thereby stabilizing the length of thread remaining after thread trimming. The feed dog does not protrude the top surface of throat plate when the sewing machine stops with its needle bar up, thereby facilitating placement/removal of the material on/from the top surface of throat plate and preventing the material from being damaged by the feed dog.

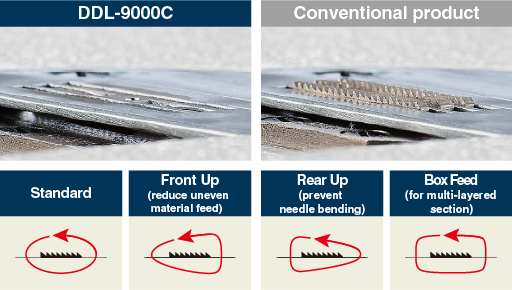

Various kinds of feed locus can be selected

Digitalized vertically- and horizontally-driven feed mechanism allows easy adjustment of settings such as the feed locus only on the operation panel according to the material to be sewn.

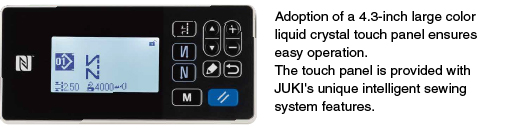

Digitalized control panel

Two different modes; i.e., the operator mode which prioritize ease of operation and the serviceperson mode, are prepared to respectively display indications according to the user.

In addition, installation of NFC enables data transfer to an Android tablet. Data transferred from the sewing machine to an Android tablet can be edited on the tablet.

Management of sewing performance and sewing machineby the utilization of IoT (Internet of Things)

Data on sewing machine adjustments made according to the product to be sewn can be transferred to a commercially-available Android tablet in contactless mode.

This enables quick check for uniform settings as well as confirmation of conditions of sewing machines in a sewing line, thereby facilitating setup changes. The operation panel is also provided as standard with a USB port. Data anagement and software update can be carried out with ease using a USB thumb drive.

Data items of sewing can be numerically managed to ensure “stable quality” and “reduction in time required for setup changes”. Quantified sewing data can be externally taken from the sewing machine using an Android tablet or USB thumb drive.

JUKI Smart APP allows you to send and confirm various data

In the application, there are items of management setting (terminal registration), sewing machine data (sewing data), problem-solution chart. In the problem-solution chart, we can generate production graphs, the availability chart, etc. for each acquired sewing machine data so it can be used for checking the current situation and analyzing it.

*Android OS Version 6.0 is recommended to use JUKI Smart APP.

(Operation is confirmed with respect to Versions 5.0 and later.)

Contact JUKI distributor in your area for how to use the application software.

Adoption of the needle-thread active tension Needle tension is digitally controlled

Needle thread tension which matches sewing conditions given can be set on the operation panel and stored in memory.

The needle thread tension adjustment needs experience. However, for this sewing machine, thread tension data stored in memory is reproducible, thereby reducing the setup time when the product to be sewn is changed.

Example: Needle-thread active tension demonstrates its effectiveness in the topstitching process.

For welting shoulders of a difficult-to-sew material, uniform stitches can be produced continuously by appropriately changing the sewing conditions even if the right and left material fabric differ in texture grain.

Active presser foot pressure mechanismThe presser foot pressure is digitally controlled

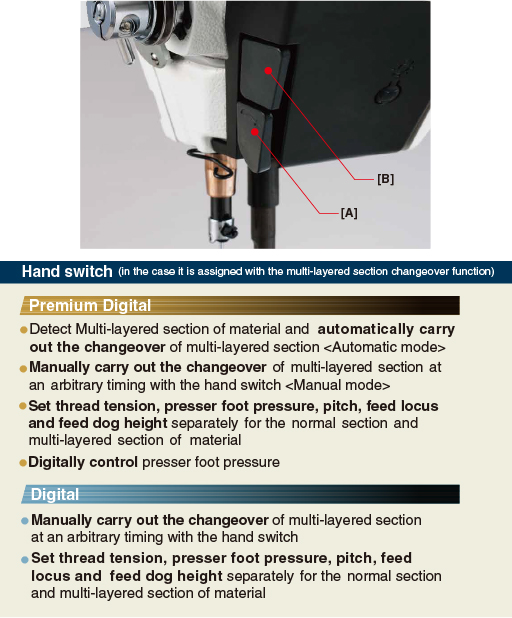

Digital control system controls the presser foot pressure. Under the automatic mode, the multi-layered section detection function detects changes in material thickness to increase/decrease the presser foot pressure accordingly.

Under the manual mode, the presser foot pressure control function is assigned to the hand switch to enable operation with the hand switch.

The active presser foot pressure mechanism demonstrates its effectiveness in prevention of stitch gathering and loose stitches.

The needle thread tension, presser foot pressure, pitch, feed locus and feed dog height can be totally changed to link their adjustments appropriately.

Needle thread clamp

The device clamps the needle thread and draws it under the material at the beginning of sewing. The needle thread clamp device works to reduce the size of thread tangling in on the wrong side of the material.

This expands the area around the needle entry, thereby allowing the use of various gauge components.Remaining thread at the end of sewing reduced to 3mm

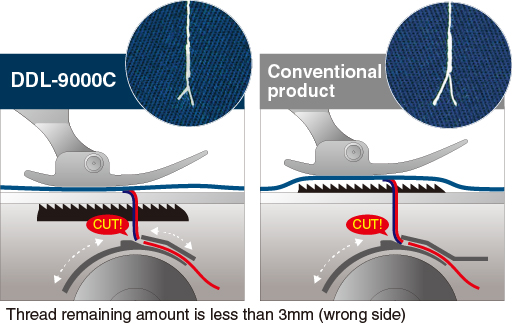

Newly adopted “double digital feed mechanism” controls up/down of the feed dog and the “double-edge driving rotary knife system” allows the feed dog to come down at the time of trimming the thread.

As a result, the knives intersect with each other just under the needle entry point.

This mechanism not only ensures the needle thread length of 3 mm or less that trails from the needle eyelet after thread trimming without being affected by the stitch length but also allows the operator to place/remove the material on/ from the sewing machine with ease.

Functions necessary for sewing machine operation can be used with the hand switch

Functions of two hand switches can be set through the operation panel. Since the reverse-feed stitching lever is provided as standard, added functions can be customized. 20 different functions (needle-up/ down correction sewing, everse-feed correction sewing, 1-time reverse-feed stitching cancellation function, etc.) are available. Highly convenient operation is enabled by setting the functions which match the sewing process in combination.

The hand switches have been factory-assigned respectively with [Α] “Touch-back switch” and [Β] “Custom switch” (to be set by the customer) at the time of shipment. The customer may assign other functions to these two hand switches.

Auto-lifter AK-154

Newly-developed auto-lifter device comes with a stepping motor. This not only increases the amount of lift of the presser foot from 8.5 mm to 13.5 mm at the maximum but also reduces the operating noise.

After the thread cutting of the sewing machine, thanks to the feature of the world's first top and bottom drive electronic feed mechanism to prevent the feed dog from protruding the top of throat plate, the material can be placed under presser foot and removed from there with ease and is not easily damaged.*To lift the presser foot to its maximum amount of lift, it is necessary to set the amount of lift in two stages.

*For the full-digital type model, the auto-lifter function is provided as standard.

Basic performance

Commitment to seam quality “Reverse-feed stitching function by means of the reverse feed lever” is provided as standard

The operator carries out fine adjustment of correction sewing (within the stitch length of 1 pitch) using the reverse feed lever, thereby achieving “further improved seam quality”.

LED light

The LED light illuminates the needle entry area in the just-under direction from the right and left sides of the needle bar. In comparison with the single-direction illumination, this LED light helps the operator carry out sewing more easily.

Illuminance of the LED light is adjustable in five levels.

It can also be used as an auxiliary lamp for working.

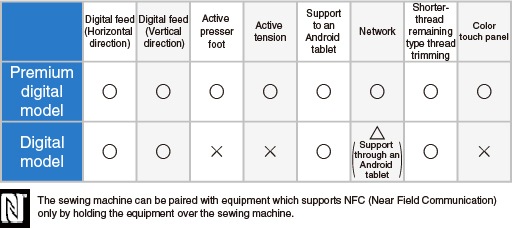

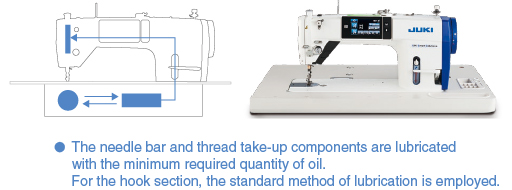

DDL-9000C Series comes in two different types

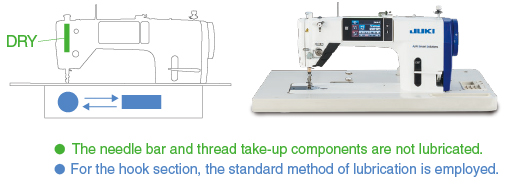

These two types of the DDL-9000C Series are environmentally friendly sewing machines that prevent the material from being stained with oil

- SMSemi-dry head typeDDL-9000C-MMax. sewing speed: 5,000sti/min*

Sewing work free from oil stains by means of our leading-edge dry-head technology.

With the advanced dry technology of enabling operation without being lubricated, a frame which does not need lubrication has been developed. It is provided with not only a high-speed sewing capability, but also a safety feature for preventing oil stains.

*sti/min is the abbreviation for “stitches per minute”

- SSMinute-quantity lubrication typeDDL-9000C-SMax. sewing speed: 5,000sti/min*

The sewing speed of 5000 sti/min, which is the highest speed of any direct-drive lockstitch machines, contributes to increased productivity.

The DDL-9000C-S is the standard model developed with the emphasis on durability. It produces seams with consistency when run at speeds which falls in the range of the highest sewing speeds.

*sti/min is the abbreviation for “stitches per minute”

Specification

| MODEL | DDL-9000C-SMS | DDL-9000C-SSH | |||

|---|---|---|---|---|---|

| Type | Digital Type | ||||

| Application | Medium-weight | Heavy-weight | |||

| Lubrication | Semi-dry | Minute-quantity lubrication | |||

| Max. sewing speed | 5,000sti/min*1 | 4,500sti/min*2 | |||

| Hand switch | Provided as standard (At the time of shipment: Hand switches are assigned respectively with the touch-back switch function and the one-touch changeover switch function.) |

||||

| Max. stitch length | 5mm | ||||

| Thread trimming method | Double-edge rotary system | ||||

| Needle bar stroke | 30.7mm | 35.0mm | |||

| Feed dog height | 0.8mm | 1.2mm | |||

| Needle thread tension | Spring type | ||||

| Presser foot pressure | Spring type | ||||

| Lift of the presser foot | By hand: 5.5mm, By knee: 15mm Auto: 1st stage 5.0 mm (*0.1~8.5mm), 2nd stage 8.5 mm (*8.5~13.5mm) *Adjustable on the operation panel | ||||

| Needle | DB×1·DP×5 (#11) #9~18 (Nm65~110) |

DB×1·DP×5 (#21) #20~23 (Nm125~160) |

|||

| Bobbin thread winder | Built in the top of machine head (provided with the bobbin thread retaining plate) | ||||

| Lubricating oil | JUKI New Defrix Oil No.1 or JUKI CORPORATION GENUINE OIL 7 (equivalent to ISO VG7) | ||||

| Size of bed | 517×178mm (distance from needle to machine arm: 303mm) | ||||

| Machine head drive | Compact AC servomotor (400W) that is directly connected to the main shaft (direct-drive system) | ||||

| Power consumption | 520VA | ||||

| Net weight | Machine head: 40.5kg (with AK-154) | ||||

*sti/min is the abbreviation for “stitches per minute”

*1 Stitch length of 4.00mm or less: 5,000sti/min; Stitch length of 4,05 - 5.00mm: 4,000sti/min

*2 Stitch length of 4.00 or less: 4,500sti/min; Stitch length of 4.05 - 5.00mm: 4,000sti/min

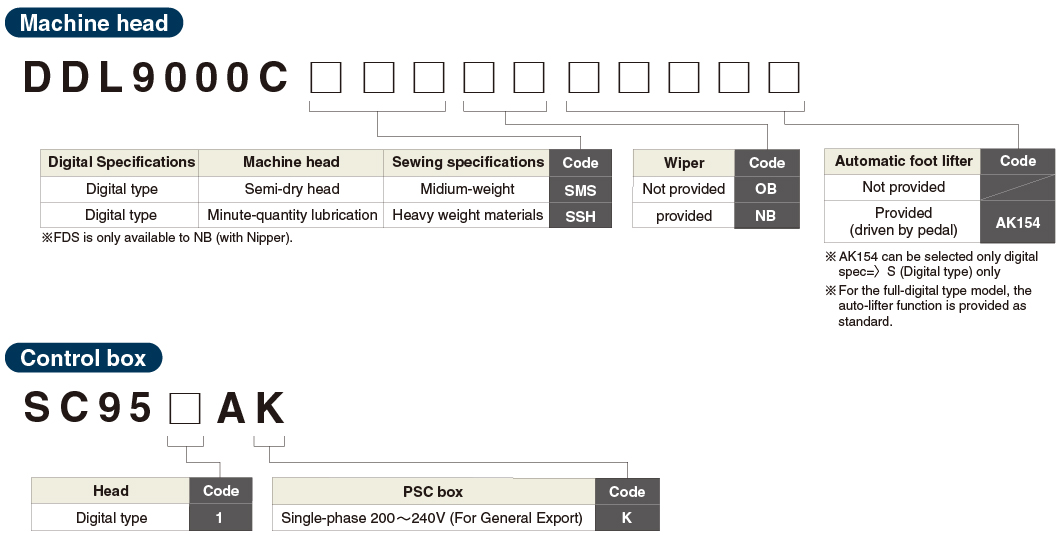

When you place orders

Gauge

DDL-9000C-SMS

| Guage | THROAT PLATE | PRESSER FOOT ASM. | FEED DOG | NEEDLE | ||||

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

||||

| Needle width | P/N | Remarks | P/N | Remarks | P/N | Remarks | P/N | Remarks |

| - | 11028008 | 3 sheets φ1.9_mm_Japan | B15240120BA | Width 1.9 | 23614506 | 3 teeth_pitch1.5_ Japan |

MDB100B1100 | #11_Organ_general_ Japan |

| - | B1109012I0B | 4 sheets φ1.6_mm_general_ Europe |

- | - | B1613012I00 | 4 teeth_pitch1.15_ general_Europe_ Shanghai |

MDB100B1400 | #14_Organ_ Shanghai |

| - | B1109552000 | 4 sheets φ1.9_inch_Shanghai | - | - | - | - | MC200500750 | Nm75_Shumets_ Europe |

| Guage | HOOK | NEEDLE BAR | BOBBIN CASE ASM. | BOBBIN | ||||

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

||||

| Needle width | P/N | Remarks | P/N | Remarks | P/N | Remarks | P/N | Remarks |

| - | 11038650 | Standard_general_Japan_Shanghai | 40086602 | Return 1.8_shankφ1.64_DLC_ general_Japan_Shanghai |

D1837555BAAA | - | 22964001 | Aluminium |

| - | 11141355 | Standard:C_with needle holder_Europe | 40086604 | Return 1.8_shankφ2.02_DLC_Europe | - | - | - | - |

| Guage | PRESSER_SPRING | SLIDE_PLATE | ||

|---|---|---|---|---|

| Figure |  |

|

||

| Needle width | P/N | Remarks | P/N | Remarks |

| - | 22907406 | - | 40172369 | Stainless_general_Shanghai |

| - | - | - | 40172367 | Iron_Europe_Japan |

DDL-9000C-SSH

| Guage | THROAT PLATE | PRESSER FOOT ASM. | FEED DOG | NEEDLE | ||||

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

||||

| Needle width | P/N | Remarks | P/N | Remarks | P/N | Remarks | P/N | Remarks |

| - | 40089605 | 4 sheetsφ2.6_no scale_general_ Europe_Japan |

D1524555EBL | Width2.2_general_ Europe_Japan |

11403003 | 4 teeth_pitcj1.8_ general_Europe_ Japan |

MDB100B2100 | Organ_#21_general;_ Japan_Shanghai |

| - | 11062007 | 3 sheetsφ2.6_no scale_Shanghai | 40064839 | Width1.9_ Shanghai |

11062601 | 3 teeth_pitch1.8_ Shanghai |

MC200501300 | Shumets_Nm130_ Europe |

| Guage | HOOK | NEEDLE BAR | BOBBIN CASE ASM. | BOBBIN | ||||

|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

||||

| Needle width | P/N | Remarks | P/N | Remarks | P/N | Remarks | P/N | Remarks |

| - | 11092251 | Thick | 40061767 | Return2.3_Shankφ2.04 | 11038759 | - | B9117012000 | Iron |

| Guage | PRESSER_SPRING | SLIDE_PLATE | ||

|---|---|---|---|---|

| Figure |  |

|

||

| Needle width | P/N | Remarks | P/N | Remarks |

| - | B1505552000A | - | 40172369 | Stainless_general_Shanghai |

| - | - | - | 40172367 | Iron_Europe_Japan |