DDL-9000CF

![]()

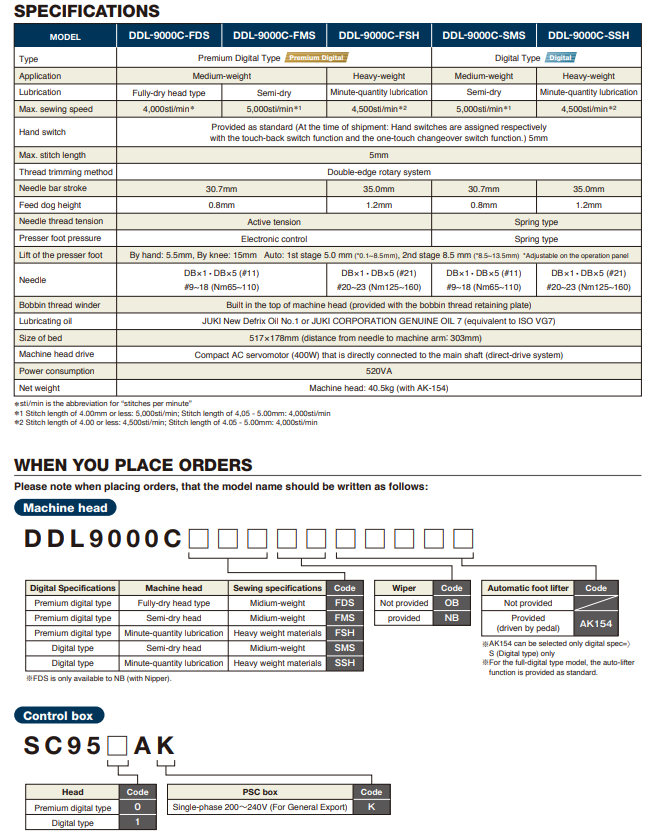

Double digital feed mechanism

Vertically and horizontally-driven digital feed mechanism

Thanks to the world's first vertically-and horizonally-driven digital feed mechanism, the feed dog height can be adjusted with ease according to the material fabric of product to be sewn, thereby improving seam quality.

Type of feed locus

Four patterns are available. All can be done with panel settings for optimum sewing to suit the material.

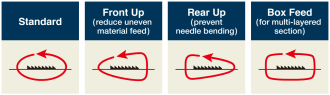

Remaining thread at the end of sewing reduced to 3mm or less

The newly adopted "double digital feed mechanism" with vertical control and double rotary knife system stabilizes the amount of thread remaining at 3 mm or less.

Active tension

Needle thread tension which matches sewing conditions given can be set on the operation panel and stored in memory.

This sewing machine, thread tension data stored in memory is reproducible, thereby reducing the setup time when the product to be sewn is changed.

(Only DDL9000CF)

Active presser foot

Not only can the pressing pressure be controlled numerically on the panel, but it is also controlled so that the pressing pressure is always constant by varying the pressing pressure according to the sewing speed.

(Only DDL9000CF)

Wide work space

The long distance from the machine arm to the needle contributes to improve workability for large sewn items such as jeans. The height also allows the operator to see the hand without disturbing the operator's line of sight.

(140mm*303mm)

Needle thread clamp

The needle thread clamp device works to reduce the size of thread tangling (bird's nest) in on the wrong side of the material. This expands the area around the needle entry, thereby allowing the use of various gauge components.

Reverse feed lever

The operator carries out fine adjustment of correction sewing (within the stitch length of 1-pitch) using the reverse feed lever, thereby achieving “further improved seam quality”.

Oil stain prevention

This environmentally friendly sewing machine prevents materials from being stained with oil.

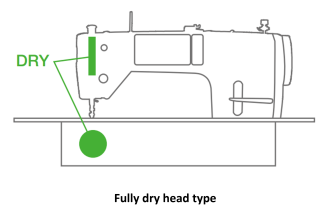

Fully-dry head type (FD)

The DDL-9000C is the comfort sewing machine that prevents oil stains on the material during sewing. It totally supports the improvement of finished seam quality. (Only DDL9000CF)

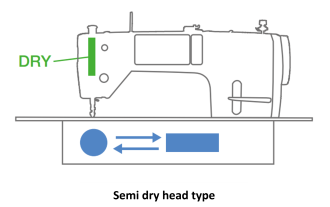

Semi-dry head type (FM/SM)

With the advanced dry technology of enabling operation without being lubricated, a frame which does not need lubrication has been developed. It is provided with not only a high-speed sewing capability, but also a safety feature for preventing oil stains.

※H type (Heavy) is only available with minute-quantity lubrication.

IoT data management

Data on sewing machine adjustments made according to the product to be sewn can be transferred to a commercially-available Android tablet in contactless mode. JUKI Smart APP allows you to send and confirm various data.

Click here to download the JUKI Smart app

LED light

The LED light illuminates the needle entry area in the just-under direction from the right and left sides of the needle bar. In comparison with the single-direction

illumination, this LED light helps the operator carry out sewing more easily.

Illuminance of the LED light is adjustable in five levels.

It can also be used as an auxiliary lamp for working.

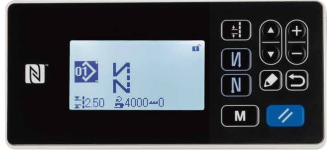

Digitalized control panel

Two different modes; i.e., "operator mode" which prioritize ease of operation and "maintenance person mode", are prepared to respectively display indications according to the user. In addition, installation of NFC enables data transfer to an Android tablet. Data transferred from the sewing machine to an Android tablet can be edited on the tablet.

DDL9000CF(Premium Digital)

Adoption of a 4.3-inch large color liquid crystal touch panel ensures easy operation.

DDL9000CS(Digital)

A black-and-white LCD switch panel and voice-guided operation instructions make it easy for operators to understand how to operate the machine.

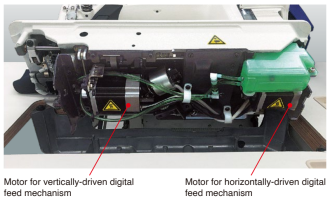

仕様