“Guide on JUKI exhibits in Texprocess2019”

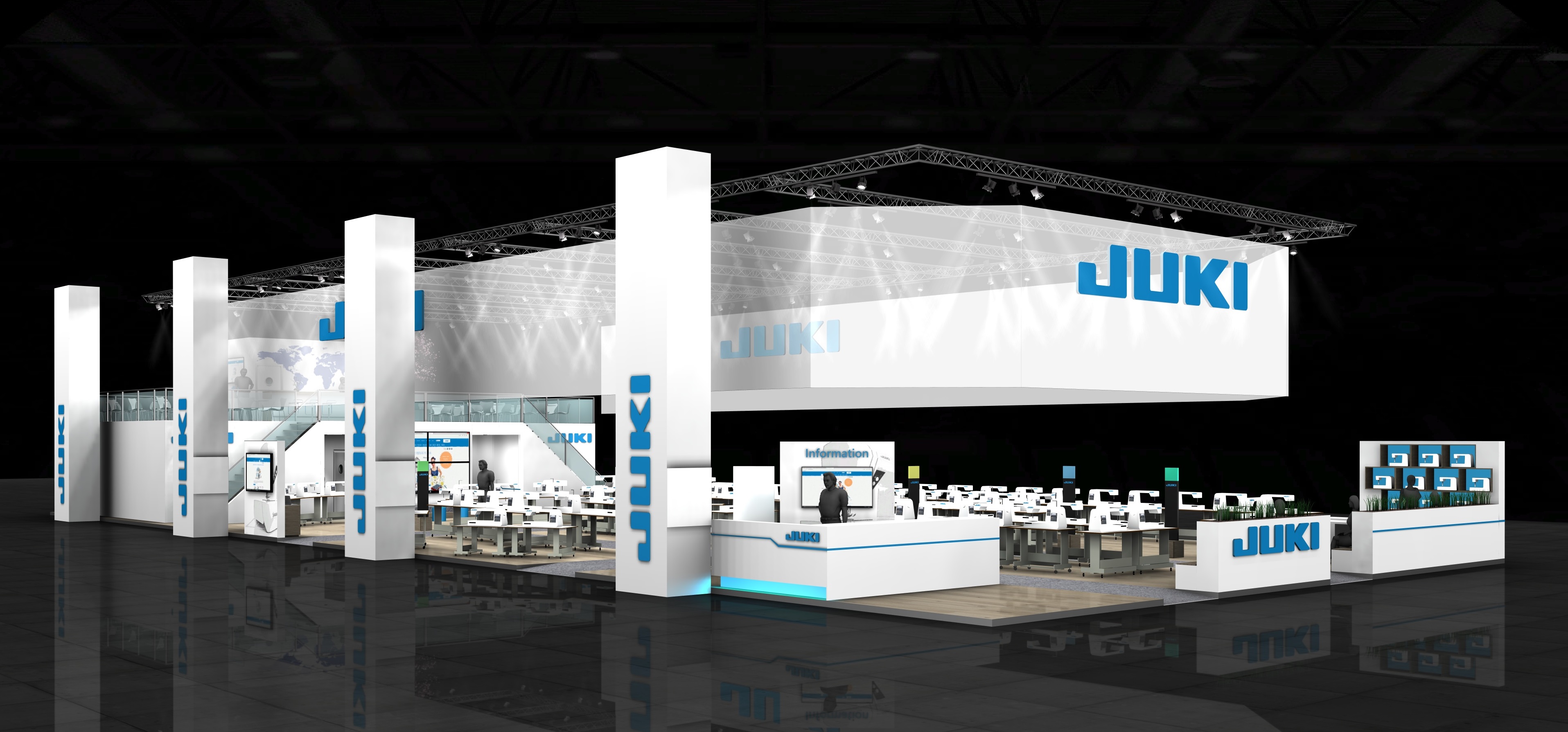

JUKI will be taking part in the Texprocess 2019 to be held from May 14 to 17 this year at Frankfurt international exhibition center (Frankfurt am Main) in Frankfurt, Germany. Seventy models (including 31 new models) of industrial sewing machines and 10 models (including five new models) of household sewing machines will be on display in JUKI booth (Booth C90 in Hall No. 5.0). The allocated exhibition space will be 656 square meters.

JUKI will be taking part in the Texprocess 2019 to be held from May 14 to 17 this year at Frankfurt international exhibition center (Frankfurt am Main) in Frankfurt, Germany. Seventy models (including 31 new models) of industrial sewing machines and 10 models (including five new models) of household sewing machines will be on display in JUKI booth (Booth C90 in Hall No. 5.0). The allocated exhibition space will be 656 square meters.

For the industrial sewing machines, with the concept of “JUKI Smart Solutions – Innovation with our Best Global Support – (JUKI globally supports you with smartification of your factories) “, solutions for total production lines are displayed. The products displayed include the automatic sewing machines for improving productivity and quality as well as the state-of-the-art industrial sewing machines incorporating highly advanced automation / digitalization technologies which complement manual work, and peripheral products intended for relevant operations other than sewing. In addition, various solutions utilizing the IoT technologies which are currently required to solve problems in sewing workshops are proposed.

For the household sewing machines, mainly focusing around the new models, the sewing machines which make the best out of JUKI’s experience and strength are introduced.

Overview of the exhibition sections and main sewing machines to be displayed

A.Section for smart manufacture line (JaNets)

1. With an eye on car seat / leather sewing, the smart manufacture line which connects digital sewing systems and network system is demonstrated.

2. With the image of workwear parts sewing / assembling line, an example of utilization of the IoT technologies for the purpose of the “visualization of production” is introduced.

B.Section for non-apparel products

In this section, sewing lines with the image of automotive interiors / furniture sewing are on display including heavy-weight sewing machines that are best suited to intended uses.

C.Section for polo shirts

The latest models are displayed in this section focusing around the image of polo-shirt sewing line. All models displayed in this section provide excellent flexibility and cost-effectiveness.

D.Section for shirts

Now, dress shirts sewing requires automatic machines. In this section, various automatic sewing machines which contribute to improved productivity and quality are introduced.

E.Section for jeans

In this section, the manufacture line for sewing aprons with jeans material is demonstrated. Labor-saving automatic sewing machines including a pocket setter (with two color threads) are introduced. This section is arranged for introducing equipment that has excellent material responsiveness, improves productivity and quality and achieves deskilling.

F.Section for sportswear / underwear

In this section, the manufacture line with the image of sportswear / underwear sewing as well as a broad range of solutions other than for sewing such as boding and garment printing are introduced.

G.Section for household sewing machines

In this section, household sewing machines including the latest computer-controlled sewing machine, sewing machine with a long arm and sewing machine specifically developed for quilting are on display. This section also includes a hands-on corner to allow visitors to actually operate the sewing machines that interest them.

New products in the respective sections

A.Section for smart manufacture line (JaNets)

AMS-251/perforation <1-needle CNC sewing machine (head turning type/perforated material sewing type)>

●Product summary

With its machine-head turning mechanism, this sewing machine achieves improved and uniform seam quality regardless of the sewing direction. With this capability, this sewing machine is best-suited to sewing decorative stitches on car seats, luxury bags and school bags as well as to sewing large products such as air bags which do not permit irregular stitches, thereby meeting the needs of various industries. Furthermore, this sewing machine produces beautifully-finished seams on perforated materials by carrying out sewing while finely correcting needle entry positions by means of JUKI’s unique image recognition technology.

PLC-2760V-7 <Semi-dry head, post-bed, unison-feed, 2-needle lockstitch sewing system with vertical-axis large hook and thread trimmer>

●Product summary

●Product summary

This sewing machine digitalizes adjustment values to be used for sewing and is able to easily transfer the adjustment value data to other sewing machines utilizing the IoT. These features contribute to substantially shortened preparation time for sewing and stabilized quality by sharing data. The sewing machine comes with the active presser foot pressure mechanism, which controls the presser foot pressure digitally to enable numerical control. In addition, the machine is provided with the multi-layered portion detection function (automatic sewing data changing) which detects multi-layered portions of material during sewing and automatically changes sewing adjustment values (stitch length, needle thread tension, presser foot pressure, amount of the alternating vertical movement of the walking foot and presser foot) according to the change in material thickness provided that those adjustment values are registered in prior to the start of sewing work.

B.Section for non-apparel products

AMS-221F <Computer-controlled cycle machine with input function>

●Product summary

The AMS-221F is a newly developed sewing machine which produces further improved seam quality. New “feed control” software for feeding sewing products as well as the feed mechanisms with increased rigidity contribute to the improved feed accuracy, thereby reducing uneven material feed which has conventionally occurred during the normal feed and reverse feed sewing. For sewing extra-heavy and hard fabric, the newly developed retry function provides the needle with an increased fabric penetrating force. In addition, the shorter-thread remaining function allows the sewing machine to shorten the length of needle / bobbin threads remaining after thread trimming to 5 mm or less. As a result, manual thread nipping after the completion of sewing is no longer required.

C.Section for polo shirts

DDL-8000A <Direct-drive, high-speed lockstitch machine with automatic thread trimmer>

●Product summary

Provided with the highly-evaluated JUKI quality and simplified functions, the DDL-8000A is a valuable lockstitch machine with thread trimmer that has been developed in pursuit of ease of use. This sewing machine comes with the vertically- and horizontally-driven thread trimmer (similar to the DDL-9000C) and the stepping-motor type presser foot lifting device. In addition, the operation panel with the audio guidance is built in the front face of the machine arm for facilitating operation and improving viewability. The operation panel has been factory-provided with simple default functions that allow the operator to intuitively know the “operation rate of sewing machine” and “work progress”. When the oil amount in the sewing machine has reduced during sewing, the voice guidance gives an audio warning.

D.Section for shirts

DLU-5494N-7/X73202/TN10<1-needle, bottom and variable top-feed lockstitch machine / turning device (for topstitching shirt collars) >

●Product summary

This is the topstitch machine for shirt collars. Thanks to its digitally-controlled material edge sensor and cloth guide, the sewing machine topstitches shirt collars with a consistent edge width. Cycle sewing of topstitches can be carried out in repetition only by setting the edge width, collar angle, material-edge finishing position, etc. on the control panel in prior. In addition, the sewing machine is installed with the TN10 (turning device) and the stacker, allowing the operator to topstitch collars full-automatically only by placing collars on the sewing machine and pressing the start button.

E.Section for jeans

AMS-221ENTS3020 / X90004 < Two-color stitching pocket setter for jeans >

●Product summary

This model of sewing machine is a pocket setter for jeans. This single unit of sewing machine is able to perform two-color stitching. In the case of performing sewing with two different color threads, it has conventionally been required to change the thread currently used with different color thread or to re-place the material on another unit of sewing machine. With this pocket setter, the operator can sew the material continuously with two color threads (two different types of thread) once he/she places the material on this single unit of sewing machine, thereby substantially saving the operator’s working time. Re-placement of the material on different unit of sewing machine is likely to cause a minute change in position of the material. The AMS-221ENTS3020, however, performs stable stitching regardless of the operator’s skill while eliminating such a minute change in position of the material, thereby improving quality.

F.Section for sportswear / underwear

LZ-2290CF-7 <Semi-dry head, computer-controlled, lockstitch zigzag stitch sewing system (full digital type)>

●Product summary

Thanks to the motor-control of the vertical- / horizontal-direction feed, feed timing changing, which has conventionally been a time-consuming procedure, can be carried out with ease by operating the operation panel. As a result, seam quality (soft standard hard) that is suited to the intended process can be set. In addition, the feed locus can be changed to prevent material slippage, thereby achieving improved material responsiveness. In addition, this sewing machine is the world’s first rotary sewing machine that comes with the active tension. Stabilization of thread tension has conventionally been difficult when the amount of bobbin thread remaining in the hook is insufficient. However, the active tension serves to correct and stabilize the thread tension even when the remaining amount of bobbin thread has reduced. Furthermore, thread tension to be employed when sewing flat portions and multi-layered portions of material can be respectively set with the multi-layered portion detection device. With these settings, the multi-layered portion detection device helps the sewing machine solve the problems such as condensed stitch pitch or loose stitches which are likely to occur on multi-layered portions of material.

G.Section for household sewing machines

HZL-NX7 Kirei < High-performance long-arm computer-controlled sewing machine >

●Product summary

Inheriting the advantages of the HZL-DX7, the HZL-NX7 has a broadened sewing space of 304 mm (12 inches). In pursuit of the enhancement of quality of straight stitches, the new “Kirei” comes with the mechanism for easily changing over the type of machine head to the exclusive straight stitch machine head (provided with the throat plate and feed dog exclusively developed for sewing straight stitches). It is also provided with the JUKI Smart Feed (built-in cloth puling top feed unit) to achieve the beautiful exterior and easily-viewable needle entry area. With these features, the HZL-NX7 is the sewing machine that allows every user to enjoy sewing on a full scale.