2 Head High-speed placement and area production are achieved

Movie Catalog download ContactFeatures

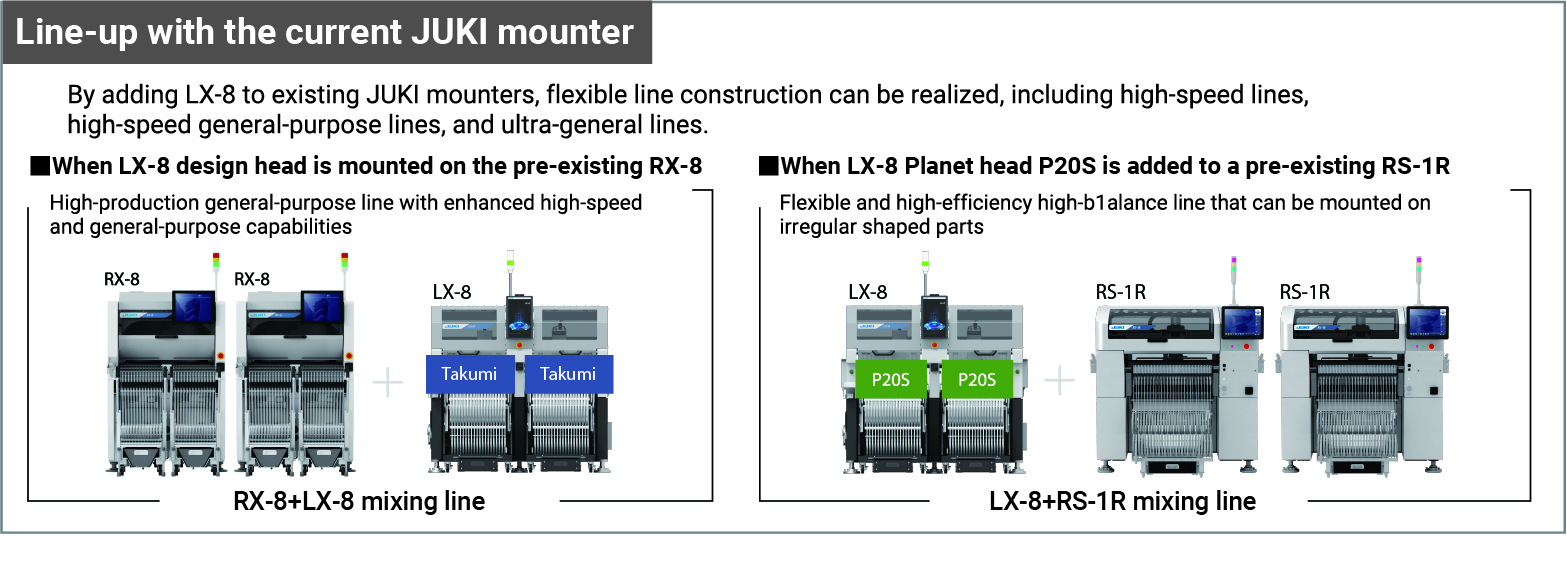

*Please inquire about Planet Head P20S

High Productivity

Achieves high-efficiency production through high area productivity and ultra-high speed equipment of the highest level in its class

It boasts the highest 105,000CPH in its class*, and is equipped with ultra-high speed, space-saving

features, while boasting high area productivity and achieving highly efficient production.

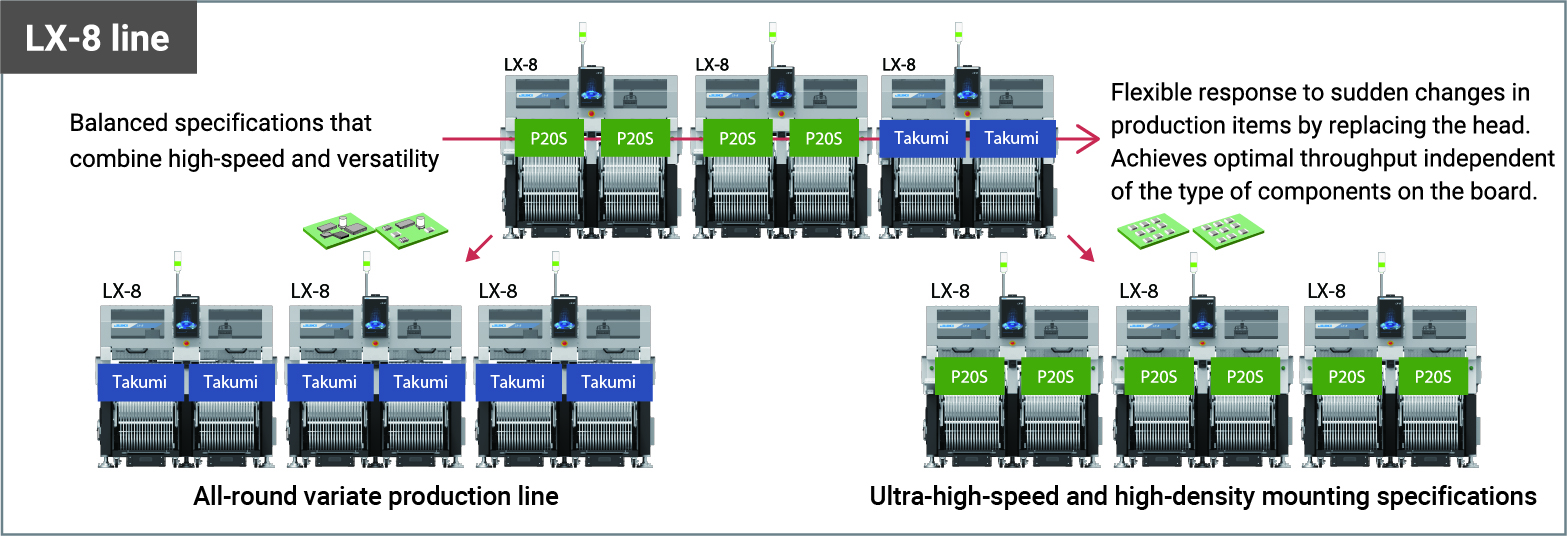

Left and right heads can be freely combined

Planet head P20S/Takumi head, selectable for each characteristic

NEWP20S head

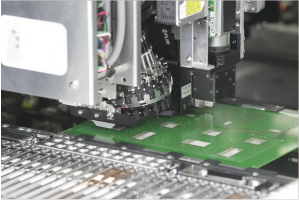

Planet head P20S has a planet-head construction that sucks continuously with 20 nozzles. Even a very small part of 0201 achieves stable suction reliability.

Takumi head

TAKUMI head for high-precision laser recognition adjusts head height to match placement component height.

High-speed mounting is realized at the optimum height from very small parts to large parts.

Feeder-mounted number-class No.1

The number of feeder slots is 160 or more, the highest in the class. Since it is possible to set the next feeder for production in the feeder bank beforehand, the setup change time can be drastically shortened,and production preparation can be simplified and made more efficient.

*Contact us for details.

NEWNew User Interface pursuing ease of use

A smartphone-like operating feel that can be operated with intuition, color-conscious for all users and easy-to-view screens in dark themes, and high-priority functions have been placed on the top screen.This is a new type of operation panel that pursues ease of use.

*Contact us for details.

High Flexibility

Head replacement

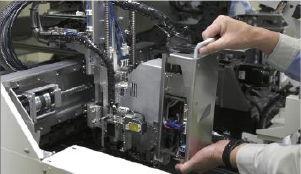

The head of LX-8 can be replaced.

By simply placing the heads optimally without changing the line layout, the machine can flexibly respond to variable and variable-quantity production.

Flexible head configuration

Head can be replaced by the user. It can flexibly respond to changes in production boards.

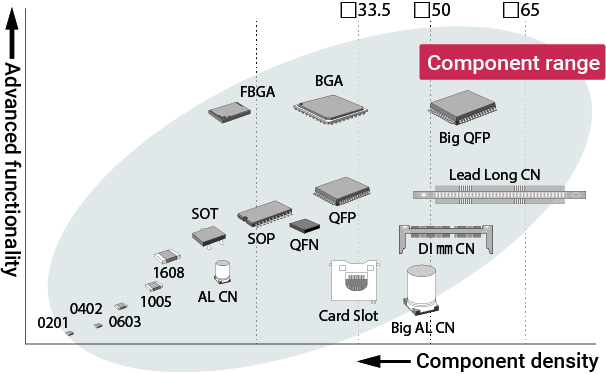

Wide component range

Supports components from 0201* (metric) up to 65 mm square or 10 x 90 mm.

In addition, component height up to 25 mm, so it is possible to mount a wide range of components.

*Contact us for details.

Large parts are supplied in trays

By using a tray server TR8 in which the main unit head sucks parts directly from the tray, it is possible to suck irregularly shaped parts such as connectors and heavy parts directly with the head.

Optimal for LED placement

With Planet head P20S, stable recognition can be achieved even with continuous-mounting, enabling high-quality mounting for producing LED indicator lamps.

High Quality

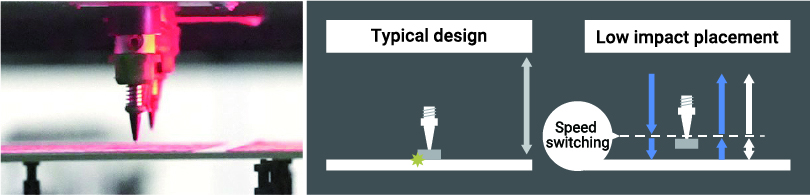

Low impact placement for flexible circuits

Low impact feature allows separately adjusting the down and up speed of the nozzle during placement. This minimizes the load on the part and on the board during placement. This is optimal for placing very small parts that require a lot of accuracy.

NEWP20S head

State-of-the-art centering and inspection vision system

With Planet head P20S, it is possible to detect the reversal of the front and back sides, inspect the tip standing, and detect the presence or absence of components. Realizes high-quality mounting of extremely small parts.

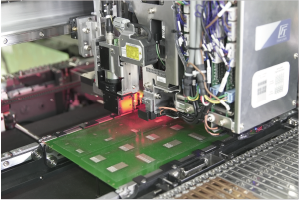

New high accuracy image-recognition for inspection and centering

Coaxial lighting technology with a new structure enables clearer imaging and realizes high-precision onboard recognition.

Takumi head

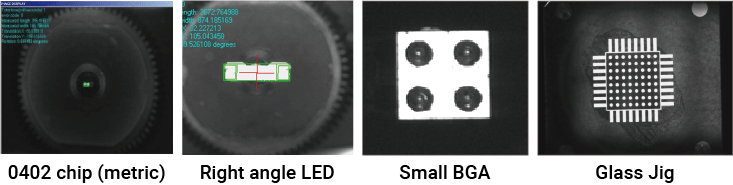

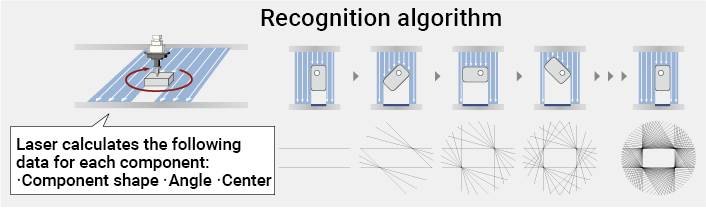

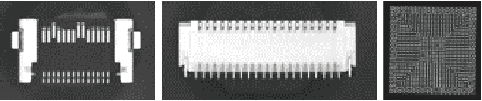

Realizes high-speed, high-precision recognition with JUKI’s proud laser-recognition technique

Various component shape can be recognized, such as SOP, QFP, BGA from 03015 minimal component to □50mm. Laser recognition realizes stable recognition and mounting without being affected by component variations such as electrode-shape and gloss.

Reduction of VCS image-recognition times

The adoption of an image-processing library HALCON has greatly reduced image-recognition times using VCS. It realizes high-speed recognition and mounting in not only chip components but also large components.

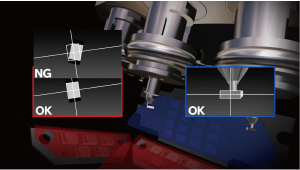

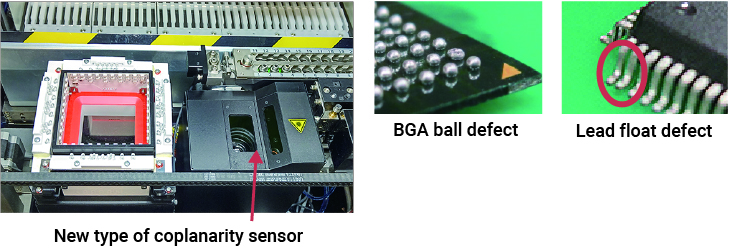

NEWNew type of coplanarity sensor

Simultaneous image-recognition and coplanarity inspection greatly improves placement tact compared with the conventional machine. High accuracy and high speed coplanarity checking prevent placement of defective component and enhance the reliability of the device.

*Please contact for detail

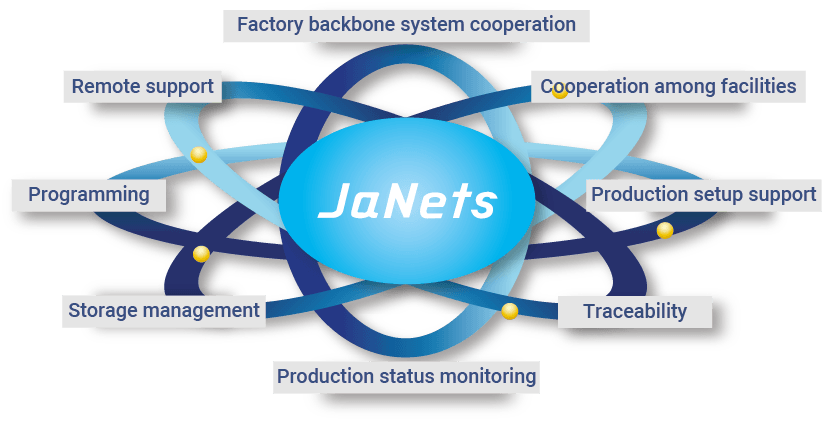

Integrates seamlessly with the production enviroment

SMT total system software JaNets and the system connected via JaNets help improve production effi ciency across the entire plant by monitoring production status, storage-management, and remote-support. In addition, IFS-NX option enables high-quality production, such as traceability and component mis-mounting protection.

Movie

Specification

| Advanced Flexible Mounter LX-8 | |||||||

|---|---|---|---|---|---|---|---|

| P20S*¹×P20S*¹ | P20S*¹xTakumi | TakumixTakumi | |||||

| Board size | Minimum | 50×50mm | |||||

| Single clamping | 410×400mm | ||||||

| Double clamping*¹ | 810×400mm*² | ||||||

| Component height | 3mm | 25mm | |||||

| Component size | Minimum | 0201*¹ | 03015 | ||||

| Maximum | □5 ㎜ | □65 ㎜ /10 ㎜ ×90 ㎜ /50 ㎜ ×75 ㎜ | |||||

| Placement speed (optimum) | 105,000CPH | 99,500CPH | 94,000CPH | ||||

| Placement accuracy | ±40μm(25μm*³)(Cpk ≧1) | ±35μm (Cpk ≧1)*⁴ | |||||

| Feeder capacity | Tape | Max. 136 | Max. 148 | Max. 160 | |||

| Tray*⁵ | _ | Max. 30 | Max. 60 | ||||

| Power | 3-phase AC200V (standard) AC200V ~ AC415V (when optional transformer is selected) | ||||||

| Apparent power | 2.49kVA | ||||||

| Operating air pressure | 0.5±0.05MPa | ||||||

| Air consumption (standard) | 50L/min(ANR) | ||||||

| Machine dimensions (WxDxH)⁶ | 1,600 ㎜ ×1,924 ㎜ ×1,440 ㎜ | ||||||

| Mass (approximately) | 2,400kg or less | ||||||

*1 Please contact for detail

*2 Factory default

*3 Image recognition, high-precision mode

*4 For laser recognition

*5 For TR8SR

*6 D dimension does not include the front operation monitor. H dimension does not include signal tower.