Would you like to worry about this?

- Some parts require humidity control

- We want to manage loose parts and cut parts

- The first-in first-out rule is not thorough.

- Parts shipping errors have resulted in double troubles

- More parts types and more complicated warehouse management

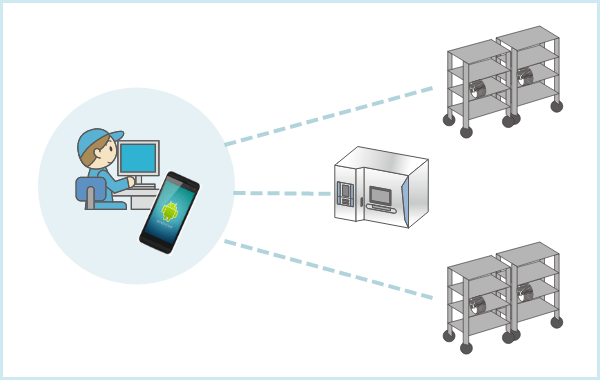

- We don't know where the parts I'm looking for

- Have ordered excess parts

- We want to reduce the burden on workers

- It is troublesome if the person in charge of the parts business takes a rest

- The parts management is not put into a database.

- We want to shorten the inventory timing proposal

- We want to shorten the lead time and use the funding

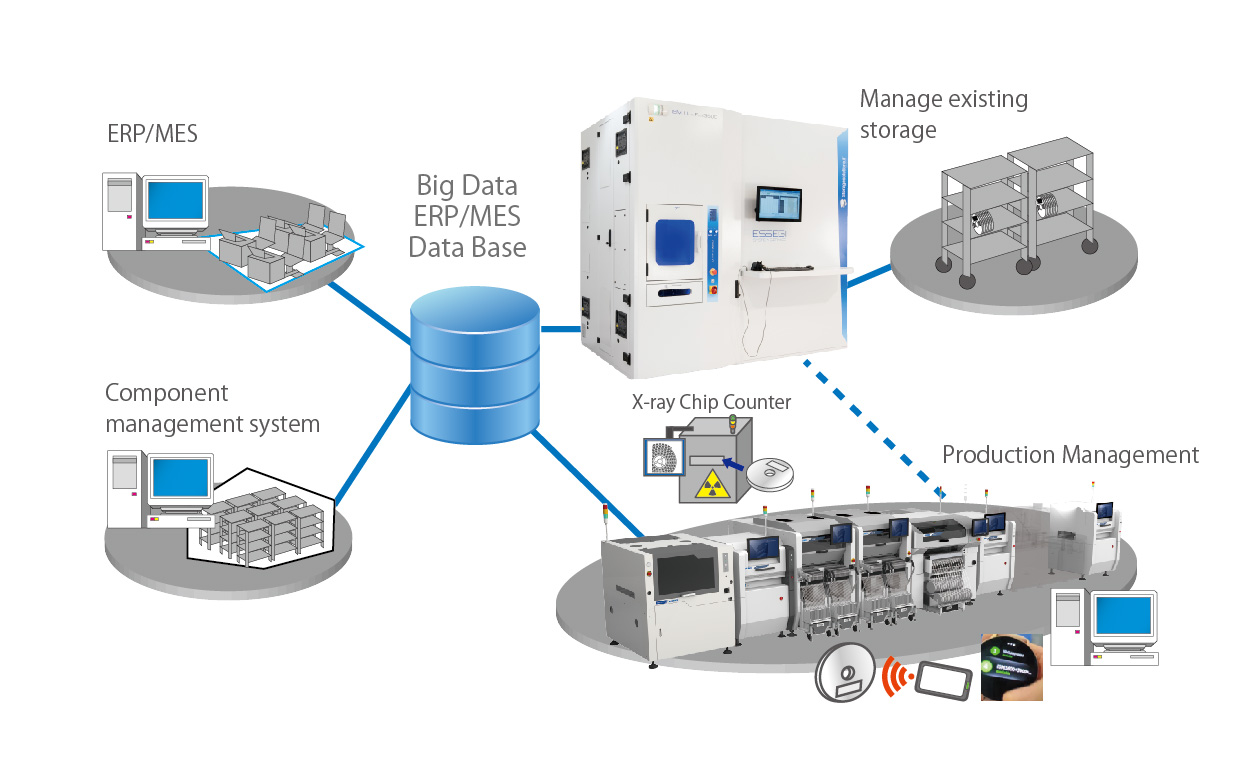

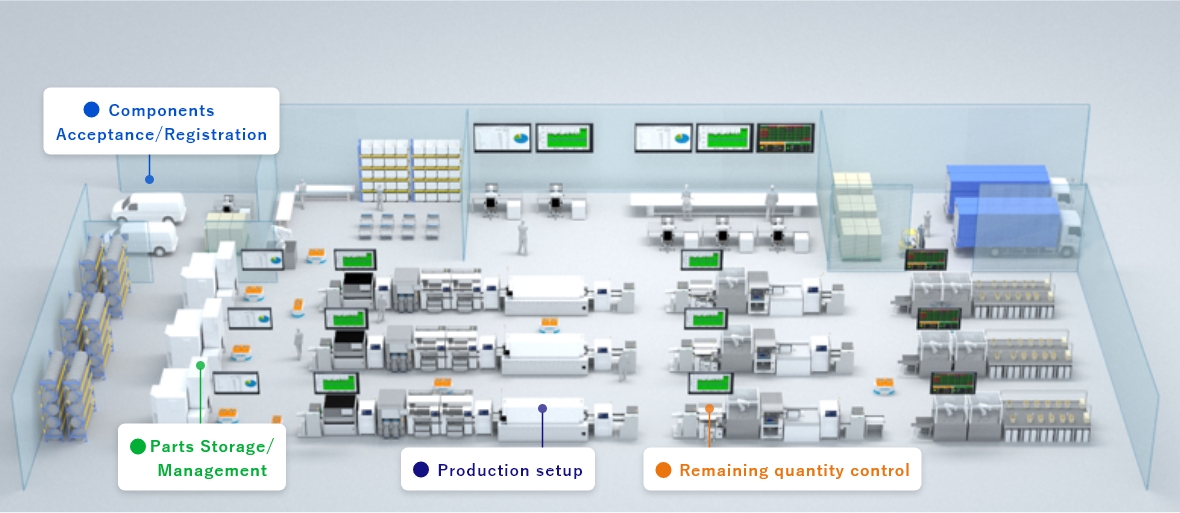

JUKI's parts management automation solution solves various problems in parts management, such as space saving and system linkage.

It can be used not only to manage electronic components but also to manage components in the assembly process.Narrow down introduction examples

- All

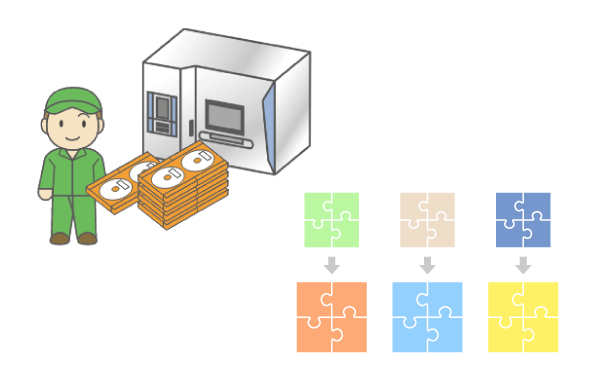

- Components Acceptance/Registration

- Parts Storage/Management

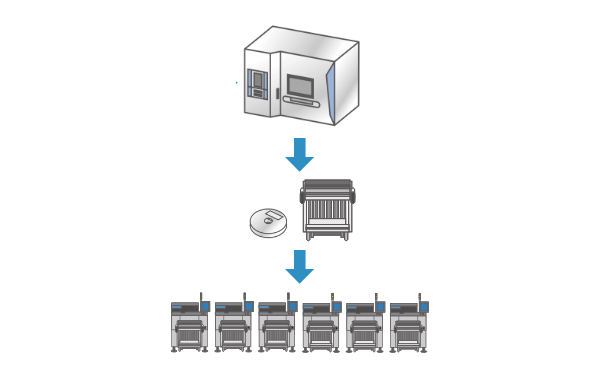

- Production setup

- Remaining quantity control