Features of the Laser Centering

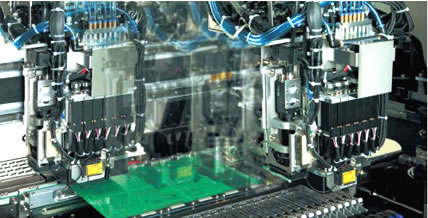

JUKI’s original technology supports the high accuracy and high repeatability required for high density placement.

High accuracy, high-speed mounting

High-speed, on-the-fly centering

on-the-fly centering

A high resolution laser is mounted on the head to center components in all directions including angle. Centering is done on-the-fly, allowing high speed placement of components from small chips to SOPs.

Adaptable centering

Centering accommodates component variations

Laser centering measures the components on the side. It is not affected by variations of component color or width/length so, unlike vision centering, there is no need to edit component data for different component vendors.

Component check function improves placement reliability

Since the laser is mounted on the head, it can be used to monitor the presence of components the entire time from pick to placement. This is difficult to accomplish with vacuum detection only. The placement reliability is also improved because the release of the component is confirmed after placement.

Since the laser is mounted on the head, it can be used to monitor the presence of components the entire time from pick to placement. This is difficult to accomplish with vacuum detection only. The placement reliability is also improved because the release of the component is confirmed after placement.