JUKI Corporation will soon launch its DX-01 Electronic Belt Feed Single-Needle Lockstitch Sewing System, a top-tier flat-bed model featuring a “six-belt feed assist mechanism” for peerless sewing precision.

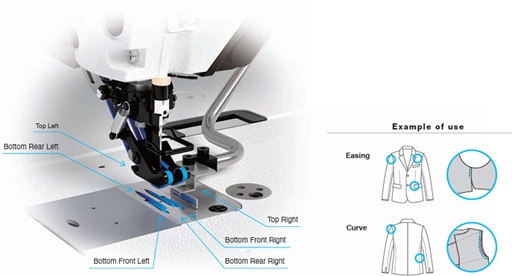

This advanced machine features a belt-feed-type assist mechanism that enables highly accurate and stable fabric feeding by precisely controlling the rotation of six belts arranged above and below the fabric. The DX-01 dramatically simplifies complex three-dimensional sewing tasks such as curved seams on shoulders and collars, as well as gathering. These operations, which have traditionally relied heavily on operator skill, can now be streamlined across a wide range of apparel items.

Sewing factories have been grappling with severe labor shortages and a decline in skilled workers due to the aging workforce in recent years. This product resolves labor shortages in sewing factories by enabling complex sewing processes without advanced technical expertise. Unprecedented levels of deskilling have now been achieved. JUKI remains committed to the proactive development, production, and promotion of products that support the sustainability of both apparel and society.

Certified under the JUKI SUSTAINABLE PRODUCTS certification system, this product not only enhances productivity and operability while reducing power consumption and improving working conditions for operators.

Click here for details https://www.juki.co.jp/en/sustainability/society/technology.html

Features

Deskilling with the New “Six-Belt Assist Mechanism” Technology

The precisely controlled upper and lower belts of the six-belt feed assist mechanism replicate the advanced fabric handling techniques of skilled operators. This system is especially effective in demanding processes that require delicate curve stitching, such as side panels, center back seams, and sleeve attachment (including easing stitching, curve stitching, and easing + curve stitching). Productivity and operator efficiency are significantly improved.

* Easing: A technique that adds fullness to a flat fabric to shape it into a three-dimensional form.

Inputting the Belt Feed Amount as a “Ratio”

By simply entering the differential amount between upper/lower and left/right belts as a ratio (%) relative to the set stitch length, the optimal feed amount is automatically configured. Although complex mechanisms often lead to difficult setup procedures, the machine offers intuitive and user-friendly feed settings and input.

Reduced Setup Time with the New “Threadless Preview Function” Concept

A key innovation in the DX-01 is “threadless preview,” a trial stitching mode where the needle stands still while the belt feed stays in motion. The threadless preview mode shortens setup times and reduces fabric waste by eliminating the need to undo stitches, an added step required with conventional “trial stitching.”

Operator-friendly Design

The system combines the intuitive, operator-friendly features of a traditional analog machine, such as a standard knee lifter lever and reverse stitching lever, with digital enhancements such as an active suspended ruler that automatically shifts left and right to match the stitch width and a trio of customizable hand switches that can be freely assigned to any of 22 functions.