Proposal of optional items for "PS-900/910 Series" to further improve productivity and sewing quality

Your Ingenuity creates opportunities for Automation.

JUKI’s unique synchronization technology controls the machine head, hook and feed mechanism, thereby creating the most favorable seams. In case of continuous circumference sewing, the sewing machine constantly detects the direction of sewing. As a result, consistent-quality seams are produced regardless of the direction of sewing.

We have prepared a lineup of 10 options "for PS-900/910 Series" to strongly support your production.

Lineup

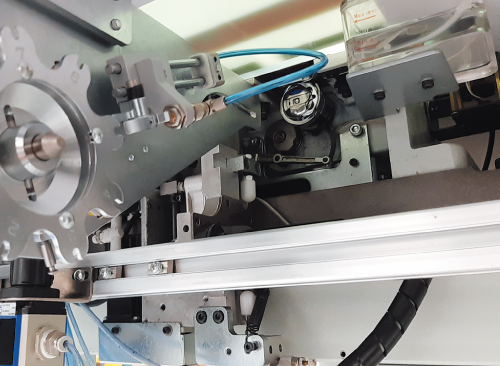

BK-10 Bobbin changer device

BK-10 Bobbin changer device automatically changes pre-set bobbin cases, saving operators the trouble of changing bobbins and increasing the production efficiency. Up to 7 spare bobbins can be set in the cassette.

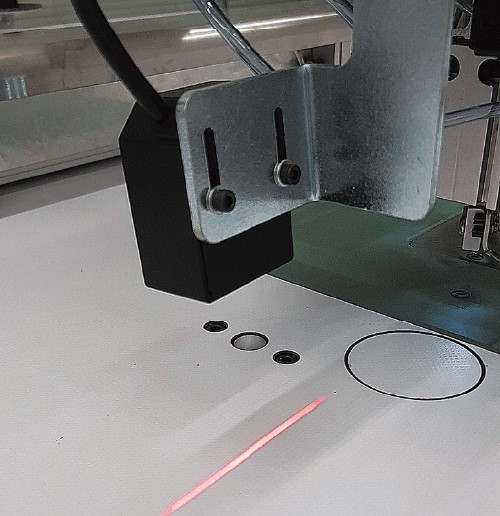

Barcode reader

The barcode reader can read the barcode pasted on the specified position of the template and call the sewing data of the template. Therefore, it is possible to eliminate human error such as erroneous recall of sewing data. Retrofitting is required if the country is not RFID certified.

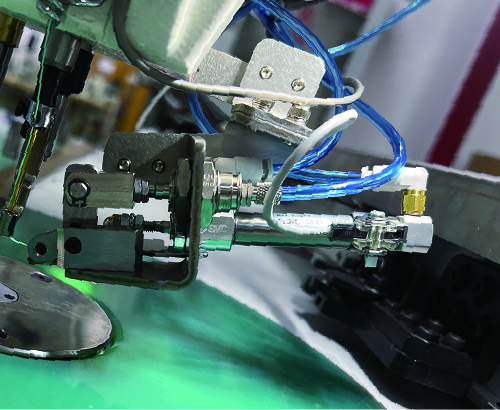

Needle thread clamp unit

The needle thread clamp unit prevents the needle thread and bobbin thread from becoming entangled at the start of the next sewing by grasping the tip of the needle thread after thread trimming, resulting in beautiful seams from the beginning.