Managerial Training Course - Production Design

- Home

- Services

- JUKI e-learning

- Managerial Training Course - Production Design

Course overview

- Course aim

- Learn and understand the optimal production line design method and system.

It also aims to "review factory lines and systems so that you can find improvements." - Target persons

- In charge of IE / Line leader

- Lecture time

- Approximately 200 minutes (Total video play time: Approximately 100 minutes)

- Supported language

- English / Japanese

Course details

Chapter 1 : What is production design?

Learn the purpose of production design and the methods to do it.

Table of contents

- 1.1Objectives of production design

- 1.2Analysis of the actual status

Chapter 2 :Organization effeciency

Learn about organization efficiency, which is a numerical representation of "Is work evenly distributed to operators?".

Table of contents

- 2.1ABC Game

- 2.2Bottleneck process

- 2.3How to obtain the organization effeciency

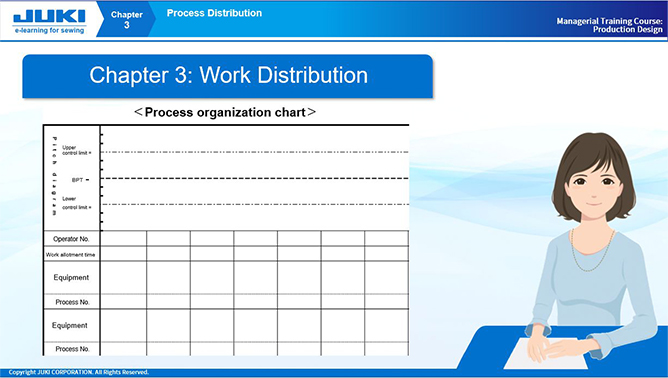

Chapter 3 :Process Distribution

Learn about process distribution using the process organization chart.

Table of contents

- 3.1Process organization chart

- 3.2Points for process distribution

- 3.3How to improve the bottleneck process

- 3.4Summary of process distribution

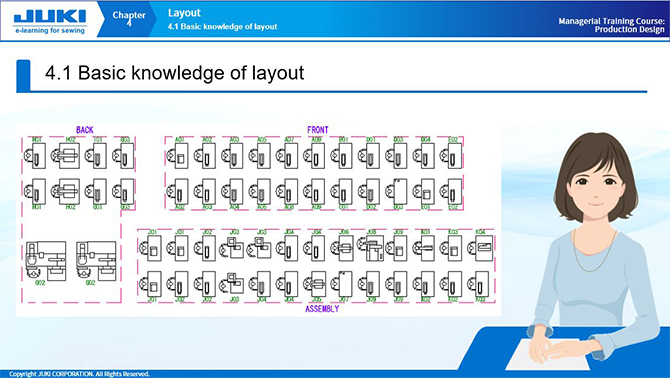

Chapter 4 :Layout

Learn about layouts that reflect process distribution.

Table of contents

- 4.1Basic knowledge of layout

- 4.2Pattern of layout

- 4.3Example of implementation

Chapter 5 :Examination of production systems

Learn about the optimal production system for mass production and vast variation in small order quantity production.

Table of contents

- 5.1Major production system

- 5.2Responding to changes in production systems

- 5.3Summary of production systems

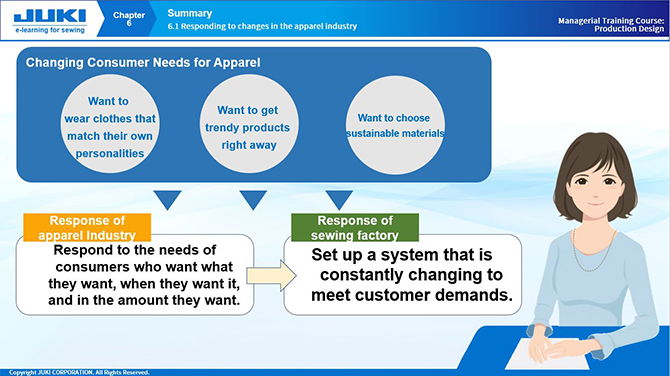

Chapter 6 :Summary

Learn how to be a highly productive factory while adapting to changes in the apparel industry.

Table of contents

- 6.1Responding to changes in the apparel industry

- 6.2What sewing factories are required to do