Basic Knowledge of Sewing - Lockstitching

- Home

- Services

- JUKI e-learning

- Basic Knowledge of Sewing - Lockstitching

Course overview

- Course aim

- Focusing on the "six major elements" that make up the lockstitch seams, participants to acquire the skills to deal with sewing problems that occur in actual sewing operation.

- Target persons

- Sewing machine maintenance staff / Intermediate-level sewing operator

- Lecture time

- Approximately 300 minutes (Total video play time: Approximately 100 minutes)

- Supported language

- English / Japanese / Chinese / Vietnamese / Hindi

Course details

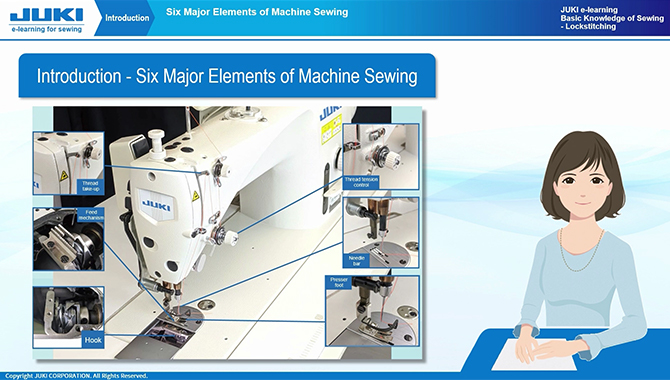

Preface: Six Major Elements of Machine Sewing

Learn about the six elements that make up a seam and their role.

Table of contents

- 0.1Types of Stitches

- 0.2What are the Six Major Elements of Machine Sewing

- 0.3Problems experienced in sewing process

- 0.4Summary

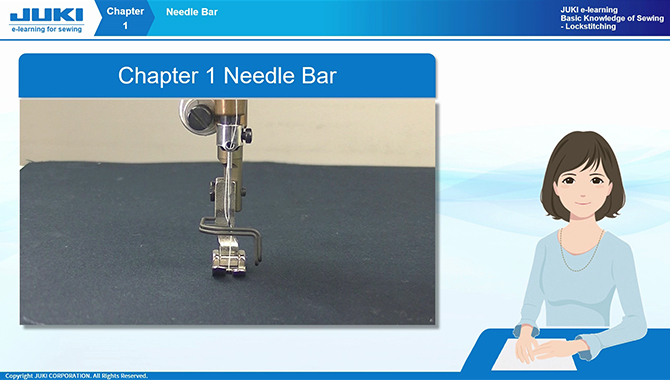

Chapter 1:Needle bar

Learn about the effects of needle bar strokes on sewing, the role of needles, and how to deal with needle sewing problems.

Table of contents

- 1.1Functions of the Needle Bar

- 1.2Needle Bar Stroke

- 1.3Functions of the Needle

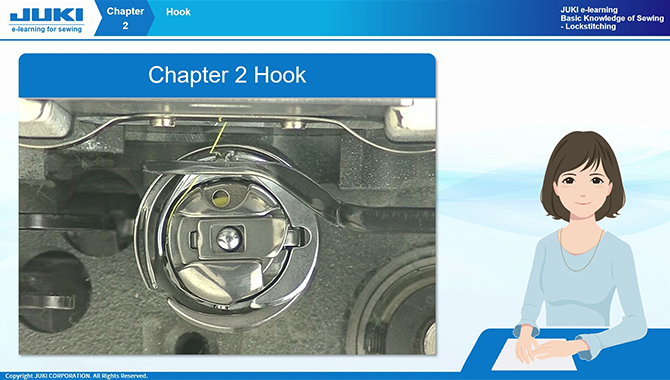

Chapter 2 : Hook

Learn about the types of hooks, their effects on sewing, and how to adjust the timing and amount of oil.

Table of contents

- 2.1Functions of the Hook

- 2.2Parts of a Hook

- 2.3Perfect Stitch and Hitch Stitch

- 2.4Types of Hooks

- 2.5How the Hook Works

- 2.6Requirements for the Hook to Work Correctly

- 2.7Range of Hook Products

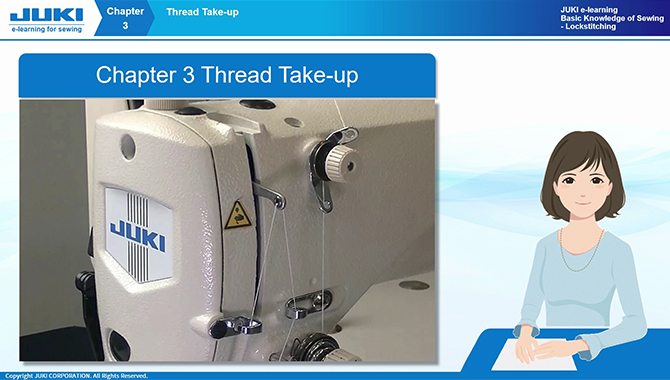

Chapter 3 : Thread Take-up

Learn about the role and type of thread Taku-up and the effect of needle thread supply on sewing.

Table of contents

- 3.1Functions of the Thread Take-up

- 3.2Type of Thread Take-ups

- 3.3Amount of needle thread supplied by the Take-up Mechanism

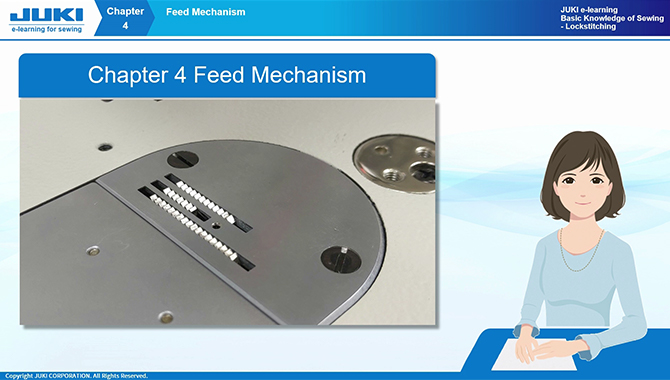

Chapter 4 : Feed Mechanism

Learn about the types of feed mechanism, the effect on the sewing of the feed dog, and how to adjust the timing of the feed upper and lower cams.

Table of contents

- 4.1Functions of the Feed Mechanism

- 4.2Types of Feed Mechanisms

- 4.3Influence of the Feed Dog on Sewing Quality: (1) Shape

- 4.4Influence of the Feed Dog on Sewing Quality: (2) Adjustment

- 4.5Feed Timing

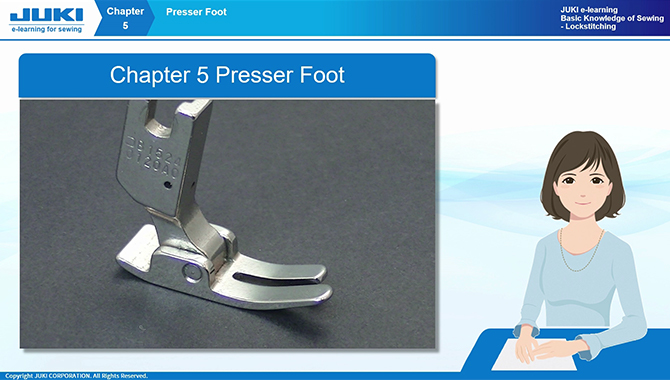

Chapter 5 : Presser Foot

Learn about the effects of different presser foot shapes and surface treatments on sewing, and the effects of presser foot pressure on sewing.

Table of contents

- 5.1Functions of a Presser Foot

- 5.2Types of Presser Feet

- 5.3Presser Foot Shapes and Surface Treatment

- 5.4Holding Pressure Given by the Presser Foot

- 5.5Daily Inspection of Presser Foot

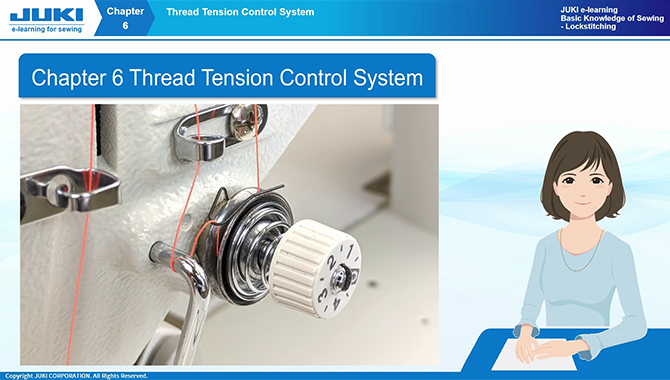

Chapter 6 : Tread tension control

Learn about the role of thread tension, threading, types of thread tension controllers, adjustment of various springs, measures against bobbin slipping, and the effects of thread tension on sewing.

Table of contents

- 6.1Functions of the Thread Tension Control System

- 6.2Correctly Threading the Sewing Machine

- 6.3Making Sewing Stitch Adjustments

- 6.4Needle Thread Tension Controlling Elements

- 6.5Types of Needle Bar Thread Guides

- 6.6Adjusting the Bobbin Thread Tension

- 6.7Bobbin Slipping

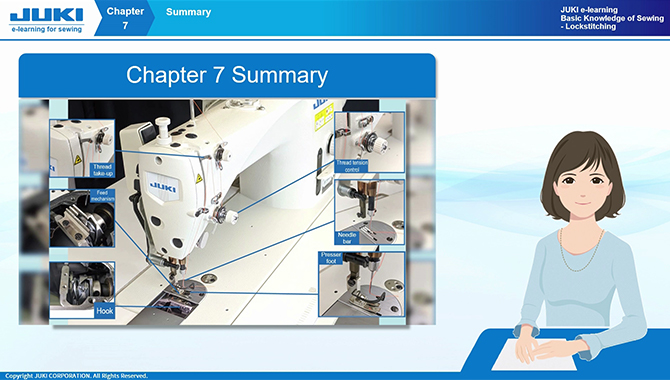

Chapter 7 : Summary

You will learn a summary of what you have learned in Chapters 1 to 6 and a correspondence table format for sewing problems that are likely to occur depending on the type of fabric.

Table of contents

- 7.1Six Major Elements of Machine Sewing and How They Affects Sewing Quality

- 7.2Problems Related to the Type of Material Being Sewn

- 7.3Basic Knowledge of Sewing - Lockstitching