Automatic 1-needle shoelace loop attaching machine

The automatic 1-needle shoelace-loop attaching machine AB-1360 is an automatic sewing machine that automatically feeds shoelace loops to tongues of sports shoes, and performs bartacking and loop folder in one process.

Product features

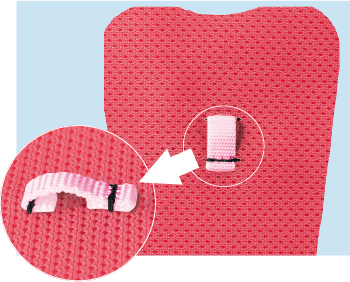

Attaching shoelace loops

The AB-1360 attaches shoelace loops to tongue section of sports shoes. Since the sewing machine is provided as standard with an LED marking light (cross-hair), accurate positioning of shoelace loops is ensured at all times. This sewing machine is able to attach shoelace loops in a series of processes (cutting, folding and bartacking of shoelace loops), thereby achieving the industry's fastest cycle time.

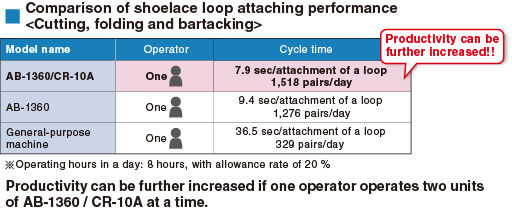

Both higher productivity and higher quality are achieved!! (AB-1360/CR-10A)

The AB-1360 / CR-10A sewing machine with a preset loader automatically feeds shoelace loops and shoe tongues to the correct shoelace loop attaching position, thereby no longer requiring manual positioning of those parts. The sewing machine is an automatic machine which realizes full-automatic sewing while eliminating inconsistency in quality and sewing position faults caused by the operator.

Deskilling

With the AB-1360, even an inexperienced operator is able to attach shoelace loops only by placing shoe tongues on the sewing machine and pressing the switch. Length of shoelace loops and their folding length can be changed with ease through the operation panel.

Basic performance

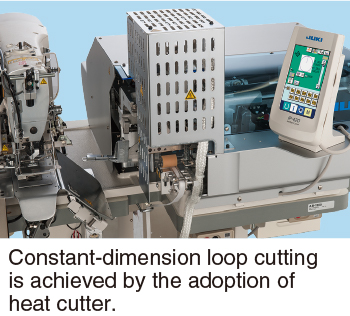

Increased productivity

With the AB-1360, not only shortening of time required for shoelace-loop attaching process but also labor-saving through elimination of preceding process (cutting of shoelace loops) can be realized. Furthermore, productivity can be substantially increased if the operator operates two units of the AB-1360 at a time. The sewing machine has adopted the electrothermal type cutter (heat cutter) for cutting shoelace loops, thereby preventing the loop material from fraying and achieving cutting of loops of constant length.

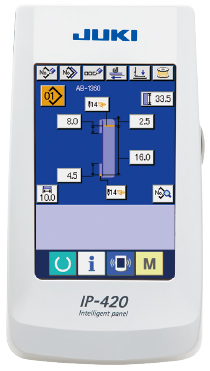

Operation panel

The AB-1360 has adopted, as its operation panel, the IP-420 which has a large color liquid crystal touch panel. With this operation panel, the operator can change the loop shape or sewing pattern.

Specification

| Model name | AB-1360 |

|---|---|

| On-board machine head | LK-1962/ABH (Specifically-designed semi-dry machine head) |

| Sewing speed (max.) | 2,500sti/min* |

| Lift of work clamp foot | 20mm |

| Hook in use | Horizontal-axis rotary hook |

| Needle bar stroke | 45.7mm |

| Needle | DP×17 (#18) |

| Shoelace loop width | 6~12mm |

| Finished length of shoelace loop | 15~20mm |

*sti/min stands for Stitches per Minute.

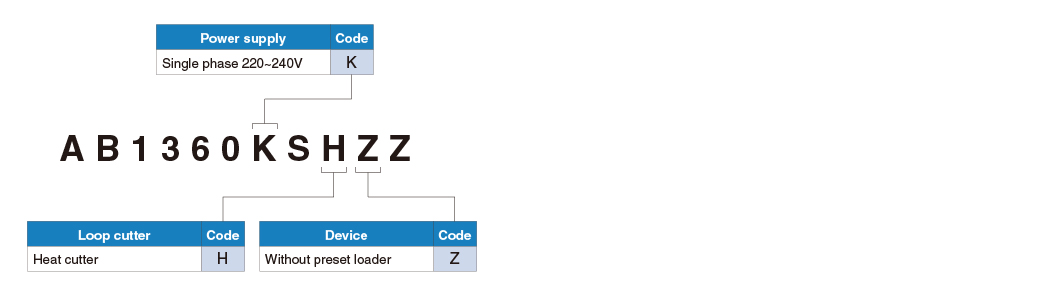

When you place orders

OPTIONAL DEVICE