Computer-controlled Cycle Machine with Input Function

(For 2-color-thread sewing)

Two-color stitching is possible by one machine.

It is suitable for sports shoes, bags and car seats such as the topstitch and parts sewing, etc.

Product features

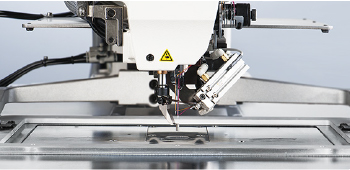

Two-color stitching is possible by changing over the needle bar

- In the case where a needle-bar changeover command is entered into a sewing pattern, the sewing machine will stop at the command position, automatically change over the needle bar and re-start sewing over the needle bar and re-start sewing with the second color thread (second kind of thread).

- The sewing operator can check the color of thread which is used with the operation panel.

The operating time is reduced

- Previously, sewing a sewing product with two kinds of thread which are different in color required the operator to change the sewing thread or to re-place the sewing product on a different sewing machine. This latest model sewing machine is able to perform sewing with two different-in-color threads (i.e., two kinds) simply by placing the sewing product on this sewing machine once. This helps significantly reduce the operator's operating time. Furthermore, possible subtle differences in position of the sewing product which can be caused by re-placing it on a different sewing machine are eliminated, thereby improving and/or stabilizing the seam quality.

- Needle bar switching speed is very fast.

Needle-bar changeover speed is fast

The needle-bar changeover speed is the fastest in the world which reduces the loss of cycle time at the time of needle-bar changeover, thereby increasing the productivity.

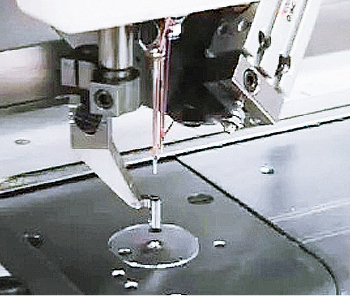

Thread retaining mechanism which clamps the thread without fail

For the needle thread changeover function, this sewing machine is provided with a needle thread suction and clamp mechanism which is not found on competitors' sewing machines. The needle thread suction and clamp mechanism clamps the thread of the needle which is at rest to prevent it from being caught by the needle which is being used for sewing. In this way, the mechanism prevents entanglement of the two threads without fail. This mechanism is also effective in preventing slip-off of the thread at the beginning of sewing.

Thread presser mechanism

The sewing machine is provided with a thread presser mechanism which clamps the thread of the inactive needle under the thread take-up lever to prevent the thread from slipping out of the needle eyelet when the thread take-up lever is operating.

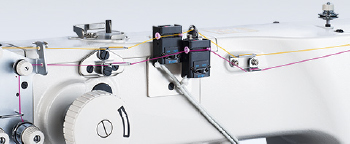

Safety mechanism

The sewing machine is provided with the wiper-returning detection sensor. It works to cause an error in case of needle thread trimming failure to prevent thread entanglement after the occurrence of the error. In addition, the sewing machine is provided with two optical sensors which respectively work to detect the flow of the two threads. This ensures highly-accurate thread breakage detection.

Basic performance

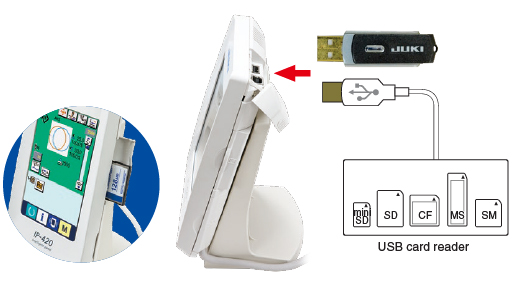

Operation panel provided with programmable functions IP-420 (provided as standard)

The IP-420 touch panel offers market-proven ease of operation. It is provided with a wide screen and programmable functions. Data can be input/edited while visually checking the needle movement. The color LCD unit displays sewing data such as stitch shape, needle thread tension, enlargement/reduction ratio, sewing speed and the number of stitches at a glance.

The memory storage capability of the main body of the sewing machine has been dramatically enhanced

Now the USB-ready main body of the sewing machine uses many different kinds of media. In addition to the Compact Flash card, the main body of the sewing machine is provided as standard with a USB connector. Now, data can be input/output to/from various kinds of media (SD (Secure Digital Card), CF (Compact Flash), SM (Smart Media), FD (floppy disks) etc.) by means of a USB thumb device and a card reader.

Specification

| Model name | AMS-221ENTS3020 | ||

|---|---|---|---|

| Application | 2-color-thread sewing | ||

| Sewing area | Monolithic feeding frame | ||

| Pneumatic feeding frame (lifting amount: 30mm) | |||

| Max. sewing speed | 2,500sti/min* | ||

| Sewing area | X : 300mm × Y : 200mm | ||

| Stitch length | 0.1~12.7mm (0.05mm step) | ||

| Needle bar stroke | 41.2mm | ||

| Lift / Stroke of the intermediate presser | Lifting amount: 20mm / Stroke: Standard 4mm (0~10mm) | ||

| Variable lower position of the intermediate presser | Standard 0~3.5mm (max. 0~7.0mm) | ||

| Needle | DP×17 (#18) | ||

| Thread | #50~#20 | ||

| Hook | Double-capacity shuttle hook | ||

| Storage of pattern data in the memory | Main-body memory : Max. 500,000 stitches, 999 patterns (max. 50,000 stitches / pattern) | ||

| External media : Max. 50,000,000 stitches, 999 patterns (max. 50,000 stitches / pattern) | |||

| Enlarging / Reducing facility | 1~400% (0.1% step), Pattern enlargement / reduction can be done by increasing / | ||

| decreasing either stitch length or the number of stitches | |||

| Bobbin thread / Product counter | Up / Down system (0~9,999) | ||

| Lubrication | Semi-dry / hook section: minute-quantity lubrication (tank system) | ||

| Lubricating oil | JUKI New Defrix Oil No.2 (equivalent to ISO VG32) | ||

| Sewing machine motor | AC servomotor 550W (direct-drive system) | ||

| Power requirement / Power consumption | Single-phase, 3-phase 200~240V/450VA | ||

| Compressed air / Air consumption | 0.6MPa, 2.8dm³/min (ANR) | ||

| Dimensions / Weight | 1,200mm(W) × 1,000mm(D) × 1,200mm(H) (thread stand is not included), 210kg | ||

* Stitch length is 4mm or less for the AMS-221EN.

* "sti/min" stands for "Stitches per Minute."

- For CompactFlash™, please use genuine JUKI products.

- "CompactFlash™"is a registered trademark of SanDisk Corporation, U.S.A.

- Microsoft Windows is a trademark of Microsoft Corporation, U.S.A., registered in the U.S.A. and other countries.

- Other company names and product names/brand names are trademarks or registered trademarks of the respective companies.

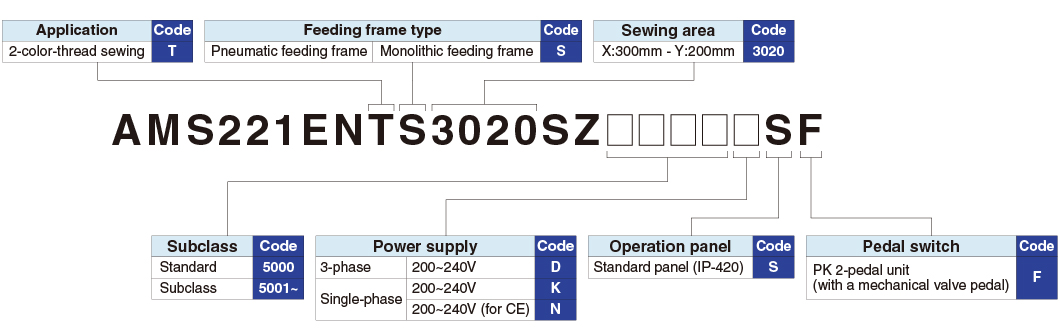

When you place orders

Gauge

AMS-221ENTS3020

| Sewing spec. | Standard | - | |||

|---|---|---|---|---|---|

| Needle size used | #14~#18 | #18~#20 | |||

| Guage | Figure | P/N | Remarks | P/N | Remarks |

| NEEDLE HOLE GUIDE |  |

B242621000B | Φ2.0 | B242621000D | Φ2.4 |

| INNER HOOK PRESSER |  |

14103352 | Needle guard 1.3mm | 14103352 | Needle guard 1.3mm |

| INNER HOOK |  |

40061991 | - | 40061991 | - |

| INTERMEDIATE PRESSER |  |

40140277 | Φ1.8 | 40140277 | Φ1.8 |

| THREAD TRIMER LEVER (SMALL) ASM. |  |

B24152800A0 | - | B24152800A0 | - |