MEB-3200C

![]()

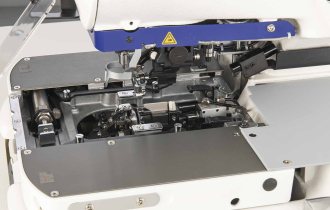

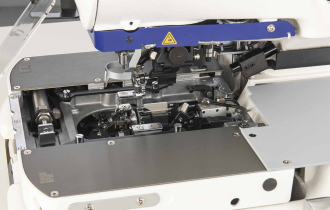

Automatized knife pressure

Significant reduction in change time of knife

Pulse motor control enables automatic control of the pressure of the cloth-cutting knife, making it possible to cut cloth with the same pressure even if the thickness or knife guard height changes.

This eliminates the need for readjustment of the pressure of the cloth-cutting knife settings during setup changes, leading to improved productivity.

Reduced knife and hammer burdens

The ability to cut cloth at the appropriate pressure keeps the life of knives and hammers, and contributes to a reduction in the frequency of parts replacement.

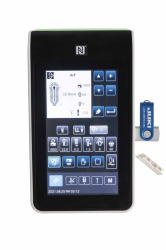

LCD touch panel

Large, highly visible touch panel for intuitive operation

Digitalization allows numerical setting of buttonholing size, shape, thread tension, and cutting pressure, and the operation panel has been redesigned with a large color LCD touch panel.

The intuitive operation shortens setting time and eliminates incorrect operation and sewing errors.

The panel is also equipped with NFC and USB, so sewing patterns and sewing data can easily be horizontally transferred to other digital sewing machines.

Knife controlled by a stepping motor

"Pulse motor control prevents poor sharpness caused by fluctuating air pressure of the knife as seen in air-driven machines.

In addition, air consumption is reduced to only 1/7 of that of a conventional buttonholing machine.

Power consumption during standby is also reduced (55% compared to conventional models)."

Active tension

Electronic control of needle and looper thread tension

The active tension mechanism automates needle and looper thread control, making it easy to reproduce the same sewing conditions for each pattern.

This allows for quick response to material changes, and greatly reduces setup and adjustment time.

Various buttonhole shapes

Wide variety of standard patterns to match all item specifications

Various buttonhole shapes can be selected on the panel by electronic control.

It equips eyelet, straight, and radial stitch buttonhole as standard, and matchs all item specifications.

(For radial stitch buttonholing, sewing data is standard, but knife and presser foot pressure are optional.)

LED light

The machine is equipped with a color-tunable LED light that can be adjusted from daylight white to light bulb color. The LED can be adjusted to suit the sewing material and environment for improved workability.

Stabilization of upper and lower threads

The lower thread path is equipped with a pipe to prevent wind, dust, and thread wear, thus ensuring consistent stitch quality.

Threading is also made easy with an attached air gun that blows in the thread.

Multi-cutting device

Multi-cutting device eliminates the need to change knife when switching between eyelet and straight buttonhole

The pressure of the cloth-cutting knife is divided into a eyelet and a straight section, allowing sewing of buttonholes of different sizes without need to change knife. (The knife of the straight part is dropped multiple times according to the length.)

This eliminates the need for two buttonholing machines, and allows for small-lot production with frequent design changes.

(Subclass)

Laser marker

Easy positioning, consistent quality, and reduced fabric setting time. Since light is emitted from both vertical and horizontal directions, the cross position does not change even if the fabric thickness changes, eliminating the need for readjustment.

(Option)

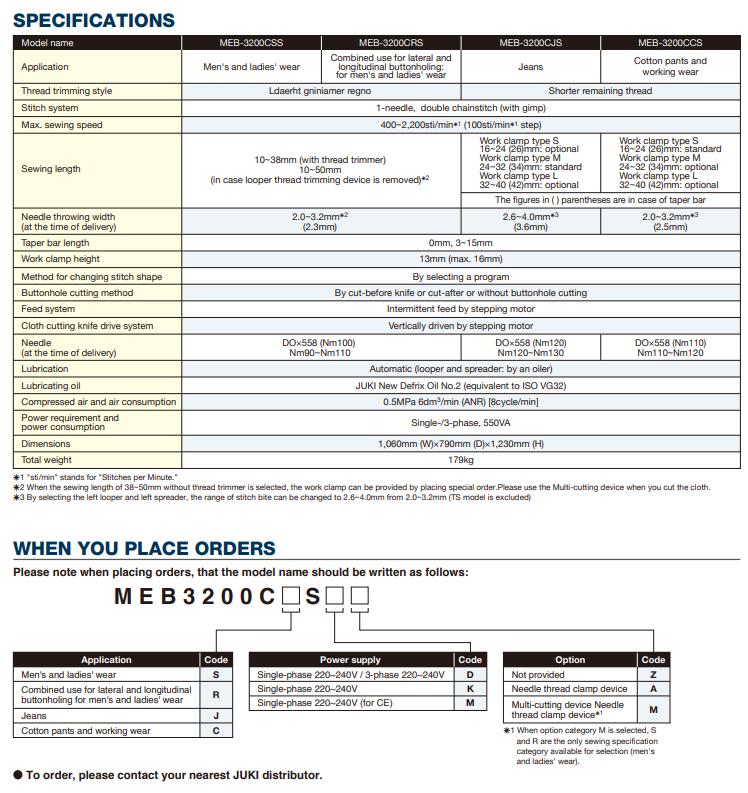

Specification