LH-4500C

![]()

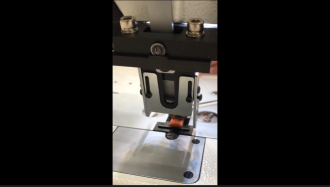

Tape cutter device

Eliminate manual tape cutting process

The tape cutter device (AT-45) improves productivity in processes such as taping, where a thread cutter cannot be used and scissors are used.

It is used a motor-driven, so its operating noise is considerably lower than that of the air-driven tape cutter.

Since air-piping is not required, the sewing machine can be moved freely in case of changing layout.

(option)

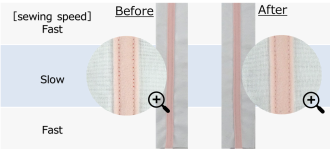

Active presser

Presser foot pressure can be set numerically on the panel according to the sewing speed.

This enables stable presser foot pressure in response to speed changes during sewing.

It is also flexible enough to change materials from thin to thick fabrics.

Multilayered portion detection

By measuring the fabric thickness of flat and multilayered areas, sewing data (pitch, presser, sewing speed, thread tension, and number of stitches) can be set for each area.

When a multilayered area is detected, it automatically switches the setting data of thread tension, etc., to prevent stitch gathering at the multilayered portion.

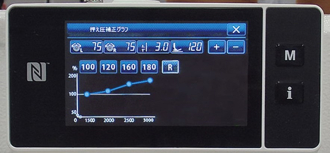

Active tension

It is possible to correct the left and right thread tension individually.

This allows the needle thread tension to be corrected individually when (1) sewing speed changes or (2) sewing conditions are different on the left and right sides.

In addition, the needle thread tension can be corrected according to the amount of remaining bobbin thread (3) by detecting the amount of remaining bobbin thread, thereby realizing stable sewing.

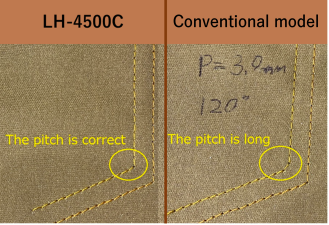

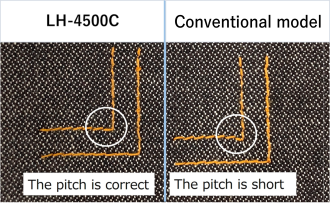

Corner stitching

Automatic correction of needle count for corner stitching

When sewing corner stitches, by setting the angle of the corner in advance, the number of stitches and stitch width are automatically set accordingly.

In processes that require a high level of skill, operation can be completed simply by switching the lever at the corner.

De-skilling reduces process time by about 50% and increases productivity.

In terms of quality, the shape of the corners does not change, and stitch defects such as floating seams on the inside corners are eliminated, ensuring stable quality. (only LH-4588C)

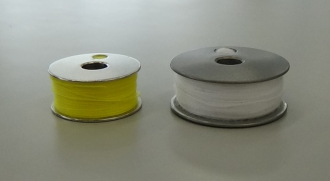

Large hook

The large hook, which was previously limited to thick material specifications, is now standard equipment for foundation (F) and medium-weight material specifications (S).

Reduced setup time

The new large hook can wind about twice as much as a standard size bobbin, which reduces the time required to change bobbins by half in a day, thereby increasing productivity.

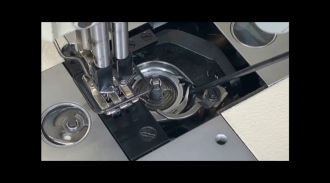

Reduction in time for adjustment

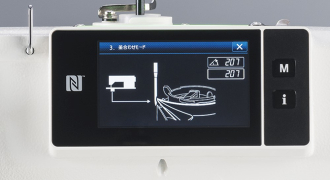

Numerical display of hook timing adjustment and thread trimming timing on the panel

The approximate position can be determined by turning the pulley by hand and adjusting the hook timing and angle suited for thread trimming timing position displayed on the panel, making adjustments easy.

Newly adopted hook driving shaft base adjustment

The new hook driving shaft allows the hook timing to remain the same even if the needle width is changed, no need to readjust it.

In addition, the needle guard adjustment of the hook has been changed to a screw type for easy adjustment.

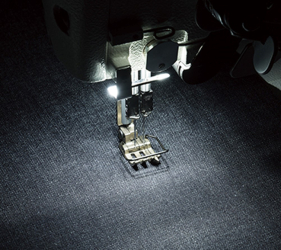

LED hand light

Reducing operator fatigue

For the LED hand light, the improved toning function with two additional colors (white / light bulb color) is provided.

The color can be adjusted according to the shade of the fabric, reducing eye fatigue of operators who spend long hours sewing.

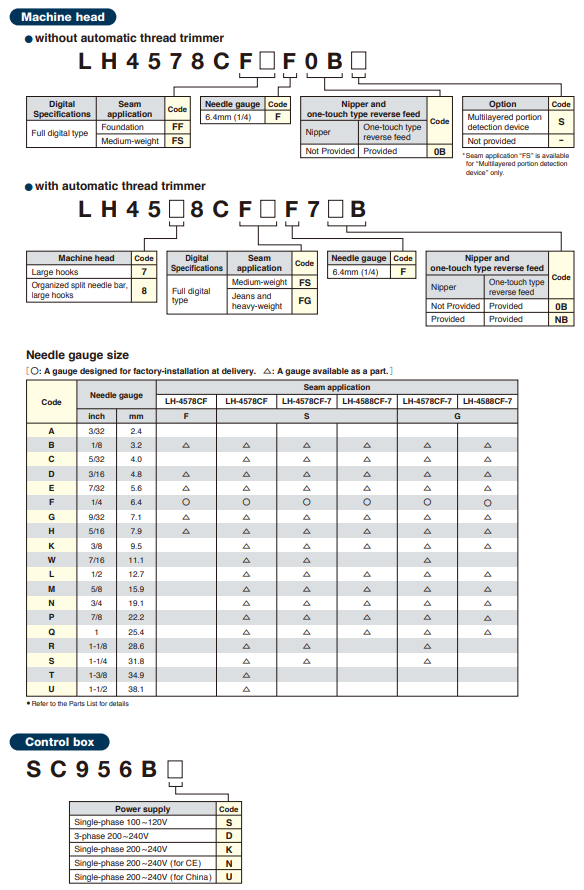

Specification