JUKI will be launching a new series of computer controlled eyelet buttonholing sewing machines, the MEB 3200C System, in April 2022. The series will be a full lineup of models for sewing items of all types. Digitized data on the buttonhole size and shape, thread tension, and knife cutting press ure for the sewing of “eyelet buttonholes” will reduce sewing setup times and ensure the consistent reproduction of stitches ideal for every sewing material. Every machine in the MEB3200C System automatically sews buttonholes and cuts them open with perfect precision.

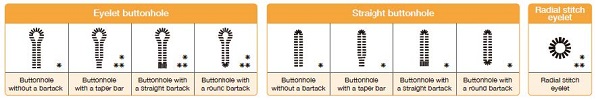

"Eyelet buttonholing" is a sewing technique mainly used to sew heavy weight materials for garments like coats,jackets, and jeans. The MEB3200C System can sew not only eyelet buttonholes, but also straight buttonholes and radial stitch eyel ets. In addition to the 11 standard patterns built in, the machine memory can store up to 99 user selected or custom patterns. The series supports all types of buttonholing by offering models for men's and women's garments, models for jeans, and models for cotton pants and working pants.

The MEB-3200C System machines operate with a newly designed color touch panel. This panel gives users full touch control of not only buttonhole size and shape, but also the thread tension and knife cutting pressu re. A new user interface (UI) is also configured for the easy setting of detailed sewing specifications, which contributes to reduce setup times and improve sewing quality.

With the recent changes in consumer behavior and diversifying customer needs, sewing factories must excel at the small lot production of widely divergent products in small quantities, as well as the production high quality products in short periods at low cost. The new MEB 3200C System offers the improved operability to support frequent

changes in sewing items. Another boost in setup speed comes with a wireless data transfer capability: by placing a tablet nearby the touch panel, sewing setting data are instantly transferred from the tablet to machine. The machines can also be used for pr oduction management by linking them with JUKI's dedicated application.

JUKI will provide Smart Factory solutions that not only improve production efficiency in sewing processes, but also connect and visualize an entire sewing factory. JUKI’s Smart Factory connect and visualize an entire sewing factory. JUKI’s Smart Factory solutions automate, digitize, and network solutions automate, digitize, and network wholewhole--sewing processes to take full control at every step, from the presewing processes to take full control at every step, from the pre--processes to the final postprocesses to the final post--process touches.process touches.

Features (New functions)

1.Color touch panel for intuitive operation

A color LCD operation touch panel comes as standard, along with a newly developed user interface (UI) to streamline the setting and confirmation of data. Operators can now intuitively check stitch shapes and set values and machine functions in fewer steps.

2.Automati zed knife pressure for increased productivity

The sewing machine comes with a vertically driven cloth trimmer powered by a stepping motor for easier setting of the knife pressure. Once the knife pressure is set, the pressure stays the same even after the k nife holder is replaced or repaired.

3.Equipped with a color tunable LED light

The sewing machine is equipped with a color tunable LED light that enables the adjustment of the daylight white color and light bulb color. The LED color can be selected to suit the sewing material and environment for improved workability.

4.Thread stabilization

A shot of air from an accessory air gun makes it easier to thread the machine head.For looper thread, a pipe installed in the looper thread path stabilizes sewing by shielding the thread from air flow from air conditioners, etc.

5. Reduced power consumption

The new motor control reduces the power consumption in standby by 55% in comparison with the conventional models and minimizes heat generation in the machine head.