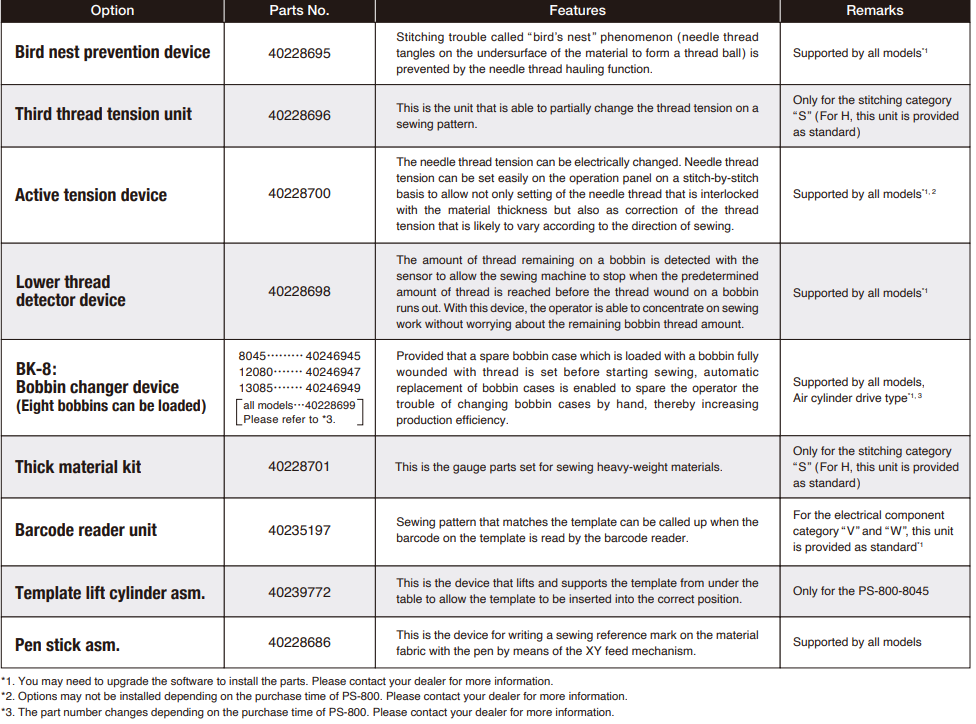

Smart Factory solutions for sewing factories proposed by JUKI: Deskilling with the pattern seamer

The challenges facing sewing factories

Do you face any of the following challenges?

Shortages of labor and young applicants; the retirement of skilled workers and aging of maintenance personnel; difficulties in handing down expertise, training successors, and training employees; the need to boost operator motivation; the demand for the small-lot production of highly diverse products; the need to facilitate setup procedures, upgrade plant management, go paperless, stabilize quality, and simplify maintenance operations...

JUKI’s digital solutions

JUKI can solve all of these challenges.

Let’s aim to create a “smart factory” with JUKI!

The pattern seamer enables sewing only by pinching parts in various sewing templates.

The sewing machine automatically sews the fabric to ensure consistent quality management,

even when controlled by a novice operator with limited experience.

The new PS-800 Series and PS-900 are engineered to realize the latest deskilling proposals from JUKI.

Each machine can automate a range of processes. The capabilities depend only on your originality and ingenuity.

JUKI is happy to deploy its pattern seamers to help customers promote the deskilling and

automation of their lines based on JUKI knowhow in pattern preparation for sewing items.

Any operator becomes useful even on their first day on the job!

Features of the JUKI pattern seamers

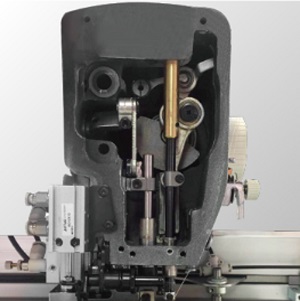

Dry head + High speed sewing

This sewing machine head introduces the world’s most advanced dry technology.Only the hook section requires oiling.

The dry structure helps achieve a maximum revolution count of 3,000 sti/min for all pattern seamer models.

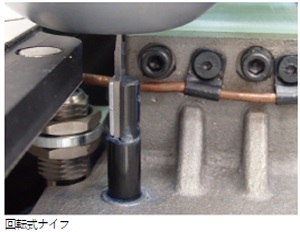

Cloth trimmer type

The cloth trimmer type is equipped with not only a laser cutter, but also a rotary knife.

Rotary knife

This knife is ideally suited to sewing products designed with both straight and curved portions.

Cloth can be trimmed after sewing by clamping the template in place.

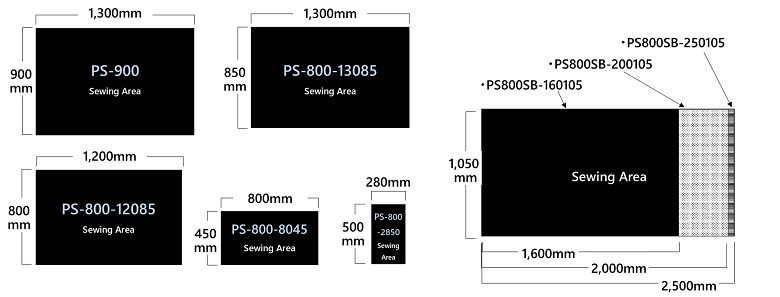

Wide-ranging sizes are available.

Five different sizes are available, including a new model that supports extra-large sizes (added to the lineup at the end of 2022).

The PS-800-8045, PS-800-6045 and PS-800-2850 are small-footprint models that can be installed in sewing lines as well as parts sewing lines.

Case studies on JUKI pattern seamers in use

PS-800HB-13085

・Sewing area ▶X: 1,300 mm, Y: 850 mm

・Case study: Sewing decorative stitches for furniture, etc.

PS-800SB-8045 with Vacuum device

・Sewing area ▶X: 800 mm, Y: 450 mm

・Case study: Sewing of kangaroo pockets for hoodies

Mini PS(PS-800SB-2850)

・Sewing area ▶X: 280 mm, Y: 500 mm

・Case study: Sewing of V-shaped slits in sleeves

Released in 2022

PS-800SB-2850

Pattern seamer Sewing area 280 mm (X) x 500 mm (Y)

PS-900

Pattern seamer with a 360° rotation needle bar

Sewing area 1,300 mm (X) x 900 mm (Y)

The PS-900 achieves sewing speeds of up to 3,000 sti/min and supports a diverse range of sewing works and materials.