We want to improve productivity and quality in collars and Sleeve plackets...

Success Story: Shirt factory

- Home

- Solutions

- JUKI Smart Solutions

- Success Story: Shirt factory

| Country | India |

|---|---|

| Manufacturing items | Men's dress shirts |

| Production quantity | 14,400 shirts/day |

| Proposed solution |

Automation

Digitization

Networking |

| Achieved benefits |

Improvements in productivity

Manpower saving

Deskilling

Improved quality |

Overview

When building a new factory of a similar scale to the existing factory, despite of little larger initial investment, our proposal of smart factory allowed the company to achieve the target ROI in a shorter period of time.

Target

Solutions

Point 1

Point 1

Automation of cutting, sewing, and finishing processes!

A number of automatic machines was proposed to the cutting process (CAM and automatic clothes spreading machine), finishing process (alliance equipment such as automatic folding machines), and sewing process (variety of automatic machines).

By automating these processes lacking manpower and time, the new factory was successful to improving its productivity with stable quality, while reducing required manpower.

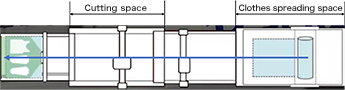

(1) Cutting process

Before

Clothes spreading by hand

Automation

After

Clothes spreading by automatic clothes spreading machines

Before

Cutting by hand using vertical blade cutting machine

Automation

After

Automatic cutting by CAM

*A smart solution to automate a series of processes from clothes spreading to cutting was proposed. Operators are engaged in the initial clothes setup and the final pickup tasks only.

(2) Finishing process

Before

Automation

After

A proposal of a finishing system line using hangers

Customer's challenge

(3) Sewing process

Before

(1) Collar process

Operation using single-needle lockstitch sewing machines

Automation

After

Replaced with PS-800 (pattern seamer)

By simply setting relevant forms, scanned RFID data from these forms empowers a single sewing machine to sew different patterns for various processes.

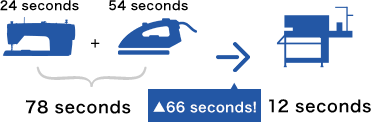

Before

(2) Sleeve placket process

Two processes are involved in the sleeve placket process (sleeve placket folding and ironing and sleeve placket sewing + stitching)

Automation

After

A sleeve placket automatic machine enabled to finish both processes with a single automatic machine, improving productivity!

Point 2

Point 2

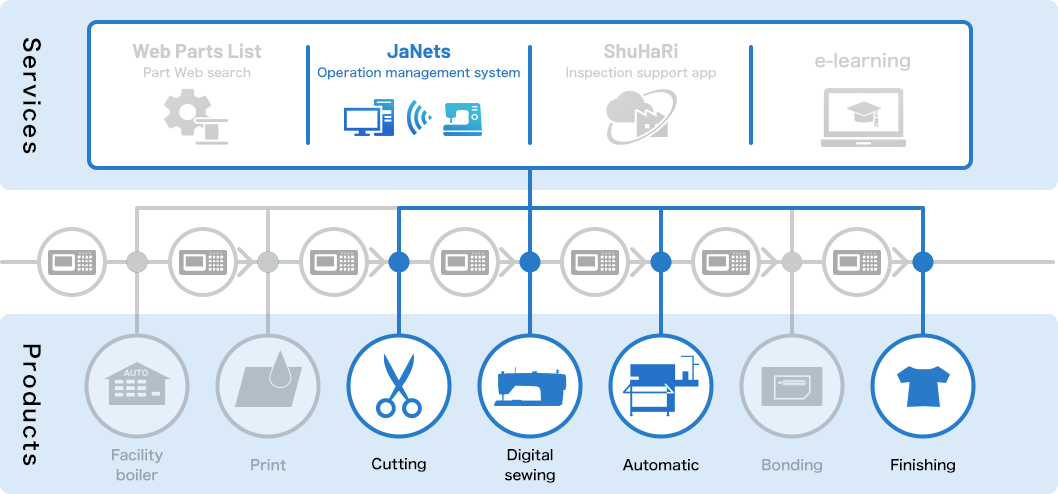

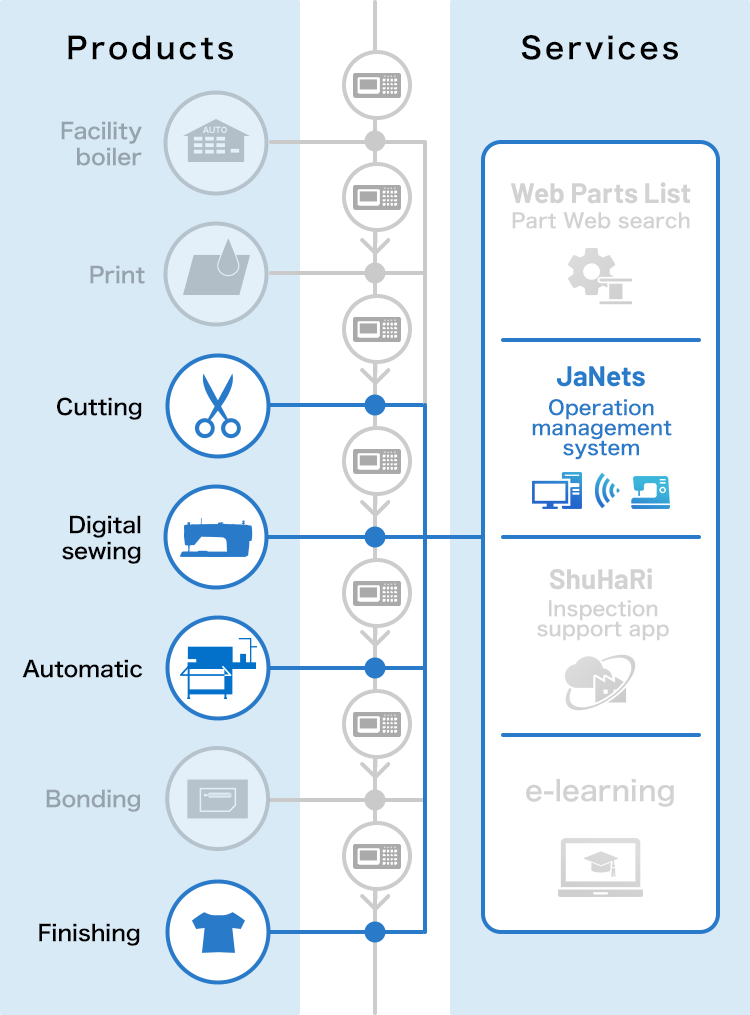

Digital sewing machines in the sewing process provide high visualization across the factory with JaNets!

By introducing digital sewing machines, the factory is successful to achieve "ideal" sewing through applying the sample data to the actual production line. In addition, JaNets, an operation management system, allowed real-time monitoring, comprehension, and management of the factory operation.

Customer's challenge

Item number changes a lot, sometimes twice or three times a day. We have to setup or tune our sewing machines...

(1) Introduction of digital sewing machines

Before

(1) Lockstitch sewing machines

Traditional lockstitch sewing machines required sewing stitching adjustments based on the fabric characteristics when the item number changes

Before

(2) Buttonholing sewing machines

Traditional buttonholing sewing machines required adjustments based on the shapes and sizes of buttonholes.

Digitization

After

Copying and pasting pattern data used in sample sewing allows sewing without sewing machine adjustments, dramatically shortening the process time

***When backing up bottleneck processes, simple copy-and-paste of data reduces the need of adjustment

(2) JaNets

Before

The production floor status could be only comprehended by a report on the following day.

Networking

After

Real-time monitoring of the production floor from the office.

Benefits

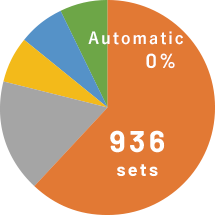

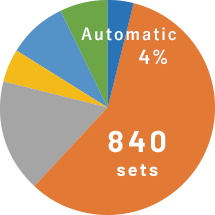

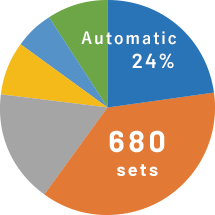

Before

Kaizen

Standard

Innovation

Smart factory

Starting from improvement from Before to Standard, then innovation is introduced by increasing the percentage of automatic machines and digital sewing machines.

By introducing automatic machines, total number of machines was drastically reduced.

-

Number of operators

1,227▶︎586 people

-

Productivity

11,680▶︎14,400 shirts/day

-

Installation space

400.1▶︎386.0m²

-

Period to achieve ROI

1.90 years