Dog ear prevention device for MOL-254

- Home

- Services

- Optional parts

- Dog ear prevention device for MOL-254

By preventing the belt loop

folded portion from protruding,

it can be sewn neatly and

cut short without waste!

Full set part No.40280415

- Quality improvement

- Productivity improvement

Contents of the set

- ●Presser footNEW

- ●Fork mechanismNEW

- ●Fullness mechanismNEW

- ●System Rom

- ●Lower plateNEW

● It is also necessary to replace the system ROM. Be sure to consult your local JUKI authorized dealer for the replacement work.

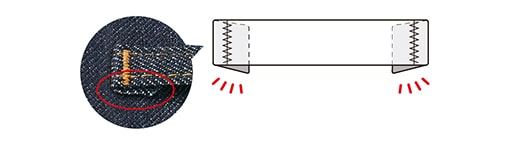

Prevents dog ears

Sample protrusion of the belt loop folded portion

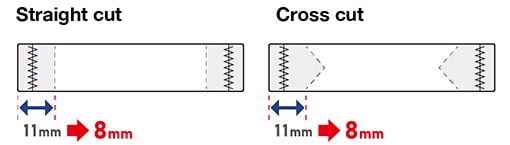

Cut length shortened

New dog ear prevention device

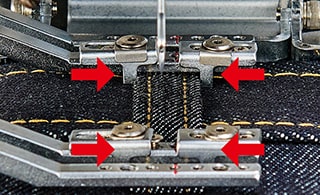

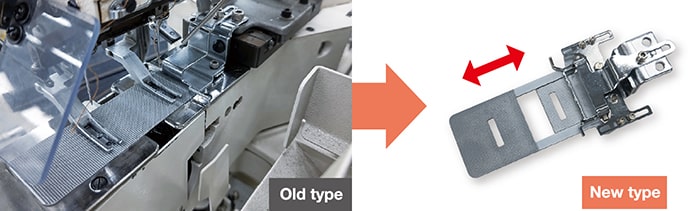

Presser footNEW

The presser foot has a tongue that holds the side of the belt loop. It holds securely even after the fork comes out and prevents dog ears. The tongue can be adjusted vertically and horizontally.

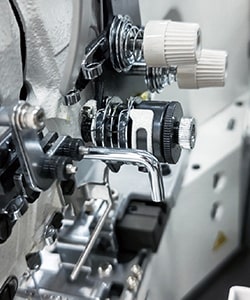

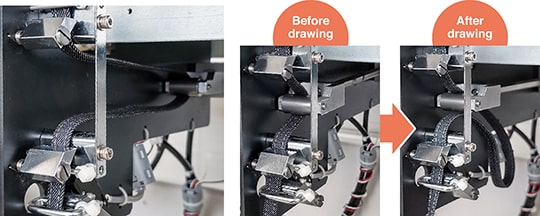

Fork mechanismNEW

The tip of the fork is now openable and can accommodate a wide range of belt loop thicknesses.

Fullness mechanismNEW

The holding of the belt loop at the fullness part has been changed from a spring type to a plate type, and it can be held securely on the entire surface. It securely holds the entire belt loop even when the fullness is not in use.

Lower plateNEW

Adjustable according to the length of the belt loop.

Previously, it was necessary to replace the lower plate when the belt loop length was changed. By making it adjustable, you can now change the belt loop length without changing the lower plate, reducing the setup time.

Introducing a wide range of optional parts for MOL-254

Belt-loop feeding device

- Quality improvement

- Productivity improvement

Part Number : G57302540A0

The belt-loop feeding device is a cylinder-type device that supports conveying the belt loop to the sewing machine main unit. It is located at the bottom of the table and pulls out the loop before supplying it, making it possible to smoothly supply the belt loop to the main unit of the sewing machine. Furthermore, a sensor detects when the belt loop becomes clogged and prevents the feeding failure.

Air gun

- Quality improvement

Part Number : G57602540A0

This is an air gun attached to the main unit. The lint accumulated during sewing can be blown away with air, which helps prevent product stains and product defects due to lint involvement.

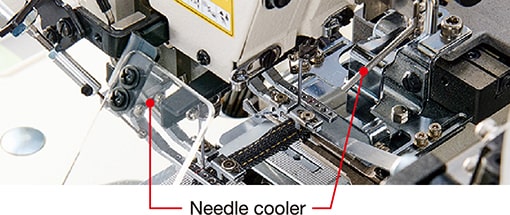

Needle cooler

- Quality improvement

- Productivity improvement

Part Number : G57702540A0

The needle cooler is attached to the needle base of a sewing machine and blows air onto the needle during sewing to suppress needle heat generation and reduce damage to the thread.

Needle thread breakage detector

- Quality improvement

Part Number : G57802540A0

It detects needle thread breakage by the thread take-up spring. When needle thread breakage is detected, sewing of the next loop is stopped, preventing sewing with a broken thread.