Post-bed, Unison-feed, Lockstitch Machine with Vertical-axis Large Hook

High-quality stitches which match the car seat designs Soft-to-the-touch stitches help create a relaxed state of mind, as if sitting on a sofa

Product features

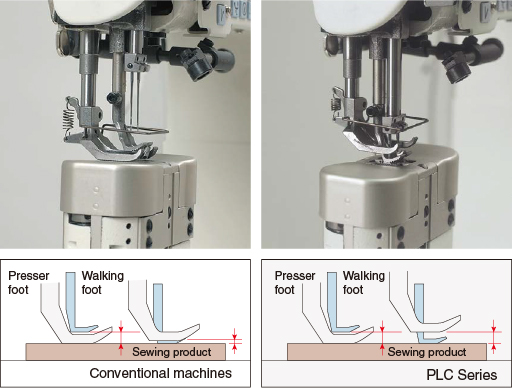

The alternating vertical movement mechanism prevents irregular stitches

- The machine comes with JUKI's unique alternating vertical movement mechanism, where the presser foot's amount of alternating vertical movement does not change even when the material weight changes.

- The amount of alternating vertical movement of the presser foot does not decrease even when a heavy-weight material is sewn. Therefore, the efficiency of the walking foot does not decrease so as to prevent uneven material feed.

- The amount of alternating vertical movement is adjustable up to 6.5mm according to the weight of the material or any multi-layered part of it.

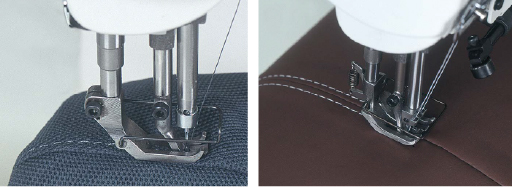

Consistent stitching performance

The PLC-1700 Series machines have substantially been improved in their overall "efficiency of feed. " The machine smoothly handles large and heavy-weight materials with an increased efficiency of feed, thereby producing consistent seams free from irregular stitches (differences in stitch length).

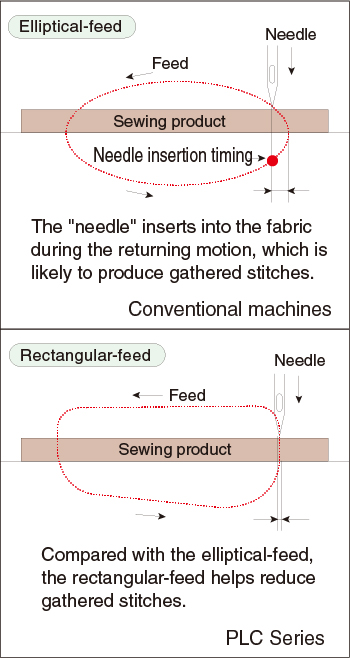

Powerful rectangular-feed mechanism

- JUKI's unique feed mechanism has been employed to eliminate stitch gathering, which is likely to occur with the conventional feed mechanism (elliptical-feed).

- The rectangular-feed locus produces an increased efficiency of feed with consistency from the beginning to the end of sewing.

- Since the feed dog's amount of lift is small, material flopping, noise and vibrations can be reduced.

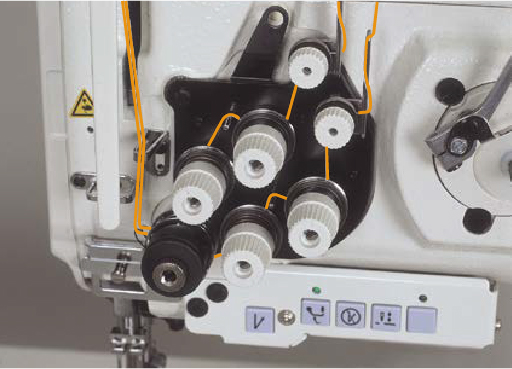

Dual-tension mechanism

The machine is able to perform sewing with low-count thread under a higher tension, which is difficult for the conventional single-tension method, with ease.

The machine comes with a dual-tension thread tension system

(two tension posts are used for a single thread).

The machine performs sewing with consistency with a broader range of needle counts up to #0

In addition, it achieves the maximum stitch length of 12mm- A triangular cam has been adopted for the feed rock cam. This enables consistent sewing with a thread count of up to 0.

- The machine comes provided as standard with a handwheel which is larger than the S type (standard) so as to increase the material-penetrating force of the needle.

- In order to ensure an efficiency of feed (presser foot pressure) which is larger than that provided by the S type (standard), a double-coil spring is equipped as standard for the pressure bar spring.

- The maximum stitch length is 12mm for both forward and reverse feed directions. In addition, the alternating vertical movement dial is provided as standard.

Basic performance

The basic performance (specifications) has been dramatically improved

- A maximum number of revolutions of 2500sti/min (increased by 25%) is achieved to increase productivity.

- The machine is able to support a maximum stitch length of 9mm (12mm for the L type).

- It is now possible to factory-install the presser foot with a center guide for 2needles at the time of delivery.

Higher lift of the presser foot

The presser foot lift is as high as 16mm, allowing the user to handle the material with ease.

Simple-setting of the amount of alternating vertical movement

The vertical strokes of the presser foot and walking foot (alternating vertical movement) can be easily changed using a large dial mounted on the top surface of the machine head. In addition the sewing speed is automatically adjusted with the set value. With this feature, ideal sewing conditions are maintained at all times.

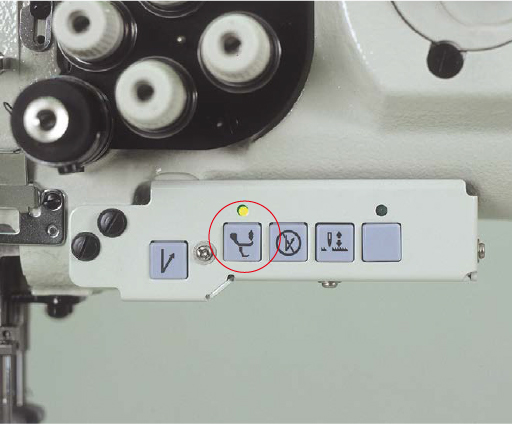

Instantaneous change-over device for the alternate vertical movement amount (DL device)

- The machine has been provided with a DL device, which demonstrates its ability in processes for sewing lots of multilayered parts of material.

- The amount of alternating vertical movement is instantly maximized by turning on the DL switch placed under the arm or the knee switch.

Safety mechanism

Even in a situation such that the thread is caught in the hook, the safety device automatically works to prevent the hook from breaking. Resetting is possible only with a button.

Thread trimming without fail

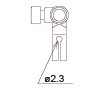

(PLC-1710-7, PLC-1760-7)- The count of thread which can be cut by the thread trimmer is TEX 50 to 135.

- The knife pressure is easily adjustable when the count of thread is changed.

Specification

| Model name | PLC-1710-7 | PLC-1710 | PLC-1760-7 | PLC-1760 | PLC-1760L |

|---|---|---|---|---|---|

| Type | 1-needle | 2-needle | |||

| With automatic thread trimmer | - | With automatic thread trimmer | - | Thick-thread long-pitch type | |

| Sewing speed | 2,500sti/min* | 1,800rpm*(P=0~10mm) 1,600rpm*(P=10~12mm) |

|||

| Needle | 134×35 Nm110~160 Standard Nm140 |

134×35 Nm140~200 Standard Nm200 |

|||

| Thread | TEX 50~135 | TEX 105~270 | |||

| Max. stitch length | 9mm (forward / backward) | 12mm (forward / backward) | |||

| Stitch adjusting method | By dial | ||||

| Thread take-up | Slide type | ||||

| Automatic reverse feed function | Pneumatic type | By lever | Pneumatic type | By lever | By lever |

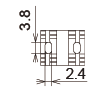

| Needle bar stroke | 36mm | 38mm | |||

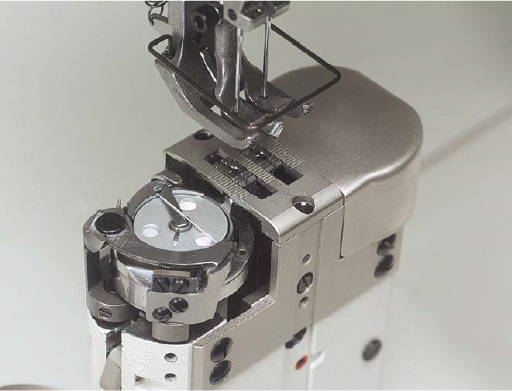

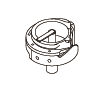

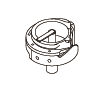

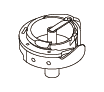

| Hook | Vertical-axis 1.6-fold capacity hook (latch type) | Vertical-axis 1.6-fold capacity hook (cap type) |

|||

| Lift of the presser foot | By hand: 9mm, Auto: 16mm | ||||

| Alternating vertical movement | 1~6.5mm | 2.5~6.5mm | 1~6.5mm | 2.5~6.5mm | 1~6.5mm |

| Alternating vertical movement adjusting method | Dial | Slot slide | Dial | Slot slide | Dial |

| DL device | Provided as standard | - | Provided as standard | - | Option |

| Safety mechanism | Provided as standard | ||||

| Bobbin thread winder | Built in the machine arm | ||||

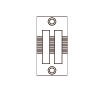

| Bottom-feedmicro-adjustment mechanism | Provided as standard | ||||

| Lubrication | Lubrication: Centralized tank method* Lubrication with an oiler for the hook section | ||||

| Distance from needle to machine arm | 255mm | ||||

| Post height | 161.7mm | ||||

| Bed size | 517mm×178mm | ||||

| Knee-lifter | - | Provided as standard | - | Provided as standard | Provided as standard |

| Auto-lifter | Provided as standard | Option | Provided as standard | Option | Option |

| Weight of the machine head | 55kg | 55kg | 56kg | 56kg | 58kg |

| Air consumption | 0.3dm³/min (ANR) |

- | 0.3dm³/min (ANR) |

- | 0.3dm³/min (ANR) |

*sti/min is the abbreviation for “stitches per minute”

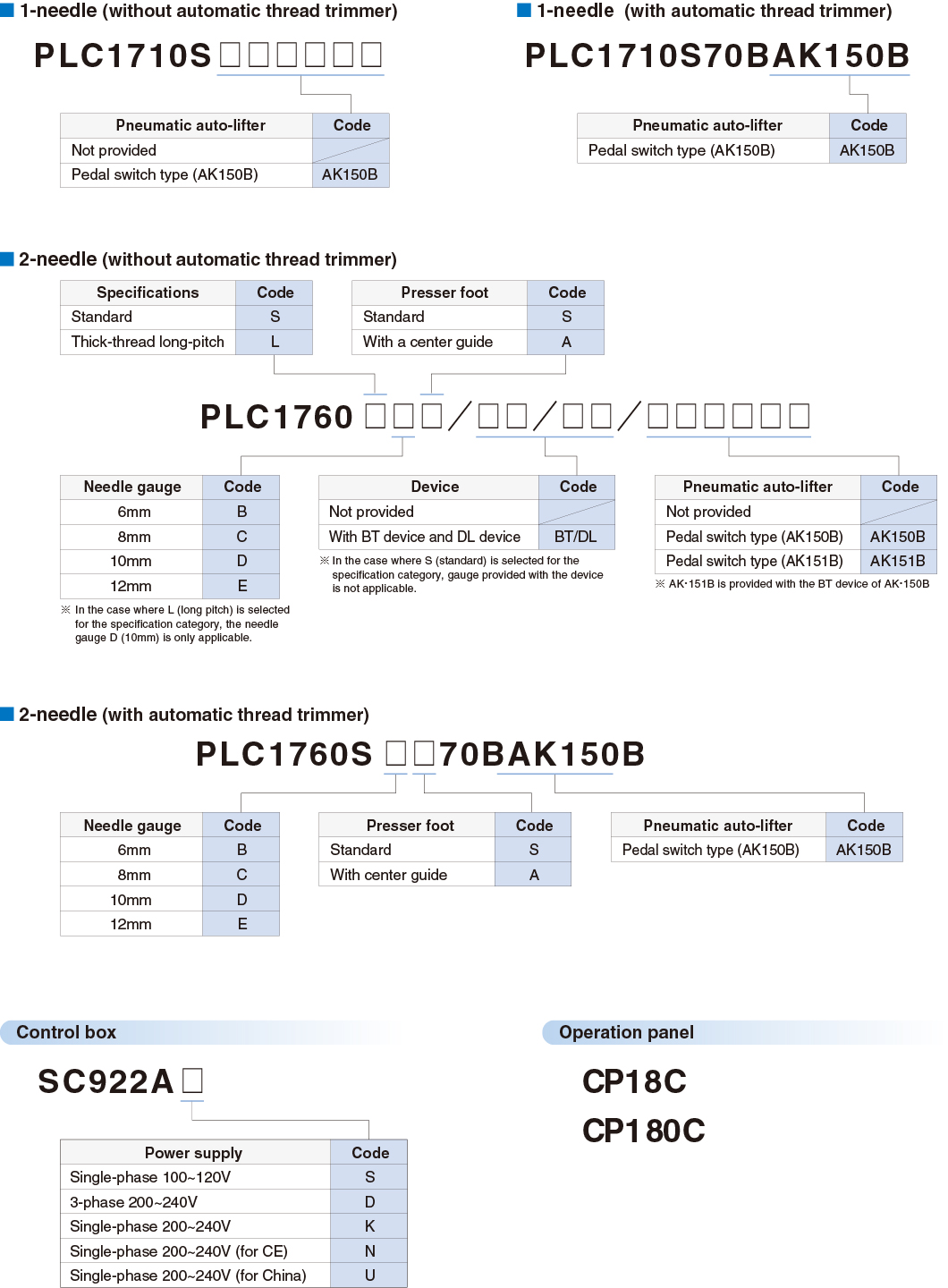

When you place orders

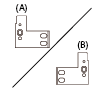

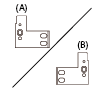

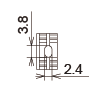

Gauge

PLC-1760-7

| Guage | THROAT PLATE | THROAT PLATE FOR ATTACHING THE LOWER TAPE | NEEDLE PLATE GUARD | FEED FOOT | FEED FOOT | FEEDING FEET FOR THE GUIDE | PRESSER FOOT |

|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

| Needle width | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 6mm | 40038759 | 40038769 | 40038790 | 40038846 | 10783157 | 40038854 | 40038800 |

| 8mm | 40038758 | 40038767 | 40038788 | 40038844 | 10783256 | 40038852 | 40038797 |

| 10mm | 40038757 | 40038765 | 40038786 | 40038842 | 10783355 | 40038850 | 40038795 |

| 12mm | 40038756 | 40038762 | 40038784 | 40038840 | 10783454 | 40038848 | 40038792 |

| Remarks | For needle thread breakage | For needle thread breakage | - | Standard | With groove | Standard | - |

| Guage | PRESSER FOOT WITH THE GUIDE | NEEDLE CLAMP | FEED DOG |

|---|---|---|---|

| Figure |  |

|

|

| Needle width | P/N | P/N | P/N |

| 6mm | 40038810 | 40038778 | 40038783 |

| 8mm | 40038808 | 40038776 | 40038782 |

| 10mm | 40038806 | 40038774 | 40038781 |

| 12mm | 40038802 | 40038772 | 40038780 |

| Remarks | - | - | Round hole |

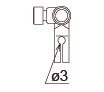

| Guage | NEEDLE | HOOKS (PAIR) | BOBBIN | MOVABLE KNIFE | FIXED KNIFE | CLAMP SPRING |

|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

| P/N | MC321001400 | 40038731 | 10759603 | 40038746 | 40038747 | 40039404 |

| Remarks | Schmetz 134-35 Nm140 | - | Aluminum bobbin (with knurling) |

- | - | - |

PLC-1760

| Guage | THROAT PLATE | THROAT PLATE FOR ATTACHING THE LOWER TAPE | NEEDLE PLATE GUARD | FEED FOOT | FEED FOOT | FEEDING FEET FOR THE GUIDE | PRESSER FOOT |

|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

| Needle width | P/N | P/N | P/N | P/N | P/N | P/N | P/N |

| 6mm | 40038996 | 40039004 | 40038790 | 40038846 | 10783157 | 40038854 | 40038800 |

| 8mm | 40038995 | 40039001 | 40038788 | 40038844 | 10783256 | 40038852 | 40038797 |

| 10mm | 40038994 | 40038999 | 40038786 | 40038842 | 10783355 | 40038850 | 40038795 |

| 12mm | 40038993 | 40038997 | 40038784 | 40038840 | 10783454 | 40038848 | 40038792 |

| Remarks | Standard | Standard | - | Standard | With groove | Standard | - |

| Guage | PRESSER FOOT WITH THE GUIDE | NEEDLE CLAMP | FEED DOG |

|---|---|---|---|

| Figure |  |

|

|

| Needle width | P/N | P/N | P/N |

| 6mm | 40038810 | 40038778 | 40039009 |

| 8mm | 40038808 | 40038776 | 40039008 |

| 10mm | 40038806 | 40038774 | 40039007 |

| 12mm | 40038802 | 40038772 | 40039006 |

| Remarks | - | - | Slot |

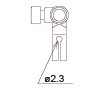

| Guage | NEEDLE | HOOKS (PAIR) | BOBBIN |

|---|---|---|---|

| Figure |  |

|

|

| P/N | MC321001400 | 40039010 | 10759603 |

| Remarks | Schmetz 134-35 Nm140 | - | Aluminum bobbin (with knurling) |

PLC-1760L

| Guage | THROAT PLATE | NEEDLE PLATE GUARD | FEED FOOT | FEEDING FEET FOR THE GUIDE | PRESSER FOOT | PRESSER FOOT WITH THE GUIDE |

|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

| Needle width | P/N | P/N | P/N | P/N | P/N | P/N |

| 10mm | 40038893 | 40038786 | 40038898 | 40039271 | 40038795 | 40038806 |

| Remarks | For L | - | For L | For L | - | - |

| Guage | NEEDLE CLAMP | FEED DOG |

|---|---|---|

| Figure |  |

|

| Needle width | P/N | P/N |

| 10mm | 40038774 | 40038897 |

| Remarks | - | For L |

| Guage | NEEDLE | HOOKS (PAIR) | BOBBIN |

|---|---|---|---|

| Figure |  |

|

|

| P/N | MC321002000 | 40038870 | 10759603 |

| Remarks | Schmetz 134-35 Nm200 | - | Aluminum bobbin (with knurling) |

PLC-1710-7

| Guage | THROAT PLATE | PRESSER FOOT | NEEDLE PLATE GUARDS (PAIR) | FEED DOG | FEED FOOT | FEED FOOT | |

|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

| Needle width | P/N | P/N | P/N | Remarks | P/N | P/N | P/N |

| - | 40038969 | 40017286 | 40038972 | A pair | 40038971 | 21444559 | 23032055 |

| Remarks | - | - | 40038976 | B pair | Standard | Standard | With groove |

| Guage | NEEDLE | HOOKS (PAIR) | BOBBIN | MOVABLE KNIFE | FIXED KNIFE | CLAMP SPRING |

|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

| P/N | MC321001400 | 40038731 | 10759603 | 40038746 | 40038747 | 40039404 |

| Remarks | Schmetz 134-35 Nm140 | - | Aluminum bobbin (with knurling) | - | - | - |

PLC-1710

| Guage | THROAT PLATE | PRESSER FOOT | NEEDLE PLATE GUARDS (PAIR) | FEED DOG | FEED DOG | FEED FOOT ASM. | FEED FOOT ASM. | FEED FOOT ASM. | |

|---|---|---|---|---|---|---|---|---|---|

| Figure |  |

|

|

|

|

|

|

|

|

| Needle width | P/N | P/N | P/N | Remarks | P/N | P/N | P/N | P/N | P/N |

| - | 40038970 | 40017286 | 40038972 | A pair | 40038971 | 40040294 | 21444559 | 40040295 | 23032055 |

| Remarks | - | - | 40038976 | B pair | Standard | For thick thread | Standard | For thick thread | With groove |

| Guage | NEEDLE | HOOKS (PAIR) | BOBBIN |

|---|---|---|---|

| Figure |  |

|

|

| P/N | MC321001400 | 40039010 | 10759603 |

| Remarks | Schmetz 134-35 Nm140 | - | Aluminum bobbin (with knurling) |